News

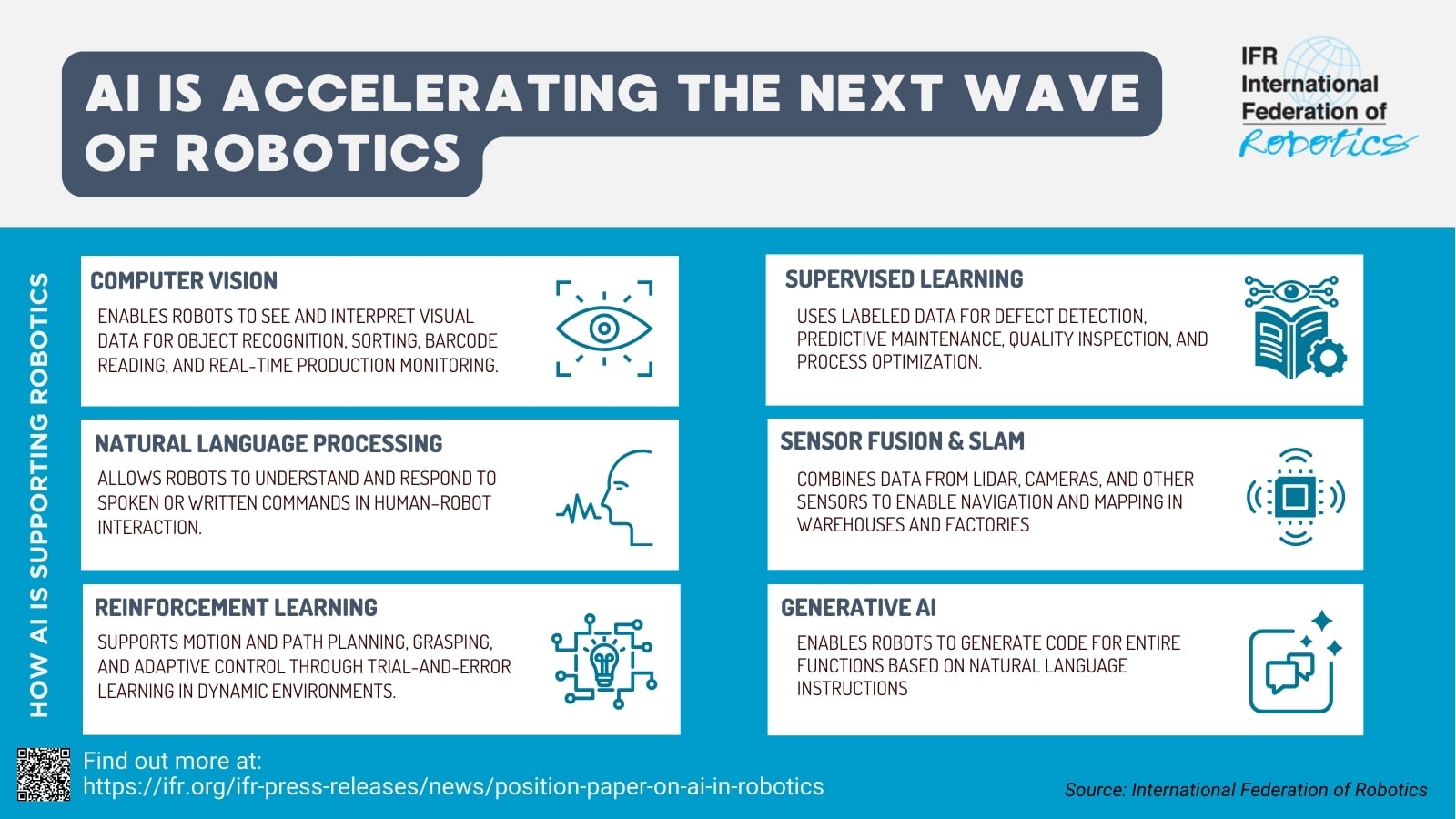

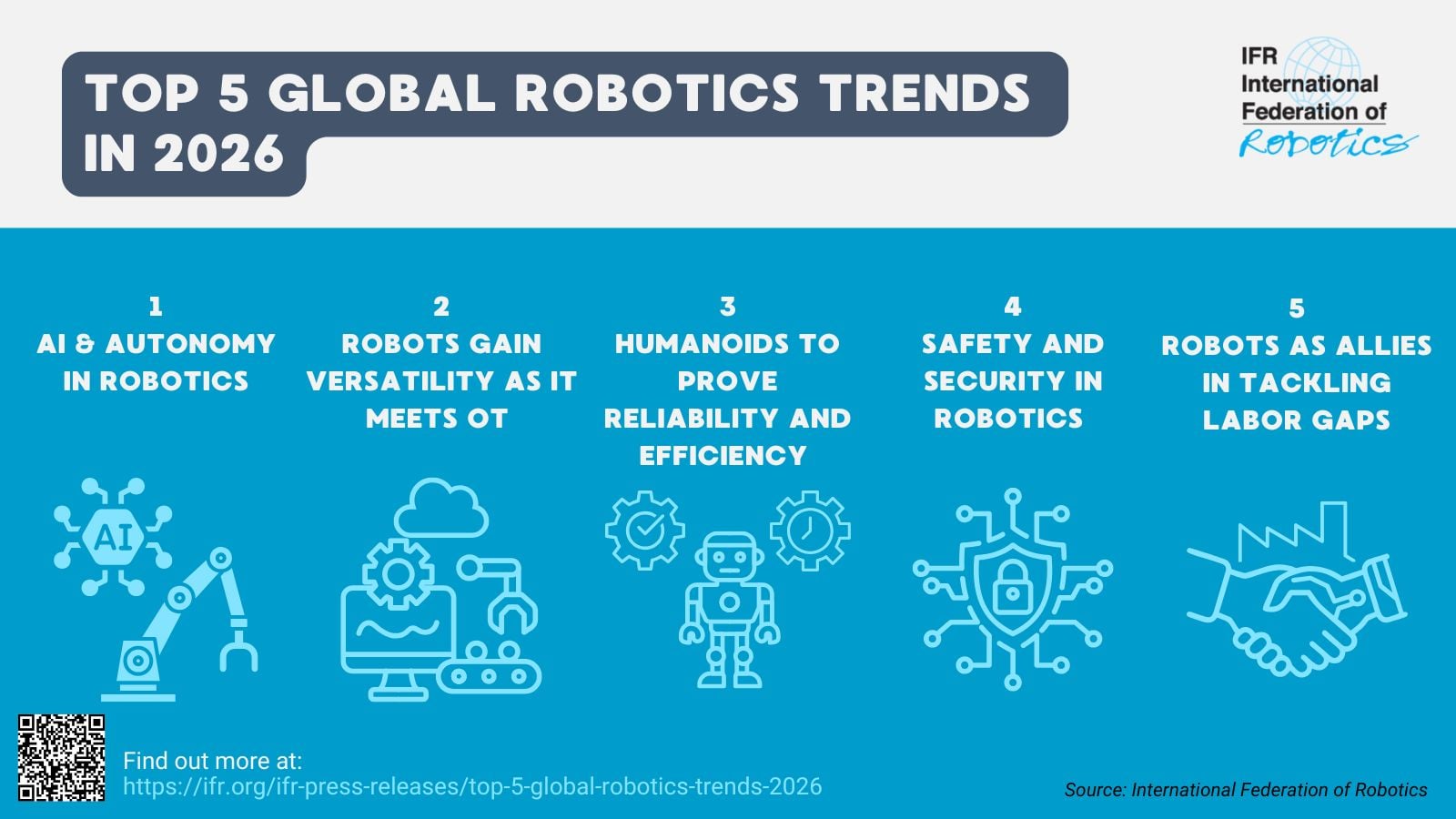

IFR position paper on AI in robotics released

AI in Robotics - Trends, Challenges, Commercial Applications

Topics and Definitions

Events

Services

Newsletter Registration

The IFR Newsletter - published quarterly - informs about sector relevant news - press releases, in-depth blogs, positioning papers and case studies on robot use. In addition, we inform about upcoming events, and new IFR members. Each newsletter highlights a report by the current IFR president. Please register for an automatic supply.

IFR Secretariat

The General Secretariat is responsible for the daily management of IFR and the coordination of all major activities, events and collaboration. The General Secretariat handles all questions regarding IFR membership.

Dr. Susanne Bieller

IFR General Secretary

Phone: +49 69-6603-1502

E-Mail: secretariat(at)ifr.org

Silke Lampe

Communication Manager

Phone: +49 69-6603-1697

E-Mail: secretariat(at)ifr.org

Credits · Legal Disclaimer · Privacy Policy ·World Robotics Terms of Usage · © IFR 2026