Timeline

-

Commemorative publication on the history of robots in Italy by SIRI

2025

To commemorate its 50th anniversary and preserve the legacy of Italian robotics, the SIRI initiated the publication of a dedicated book, that not only traces SIRI’s journey but also highlights Italy’s pioneering contributions to robotics even before the Association’s founding. Find our more at 50th Anniversary of SIRI

To commemorate its 50th anniversary and preserve the legacy of Italian robotics, the SIRI initiated the publication of a dedicated book, that not only traces SIRI’s journey but also highlights Italy’s pioneering contributions to robotics even before the Association’s founding. Find our more at 50th Anniversary of SIRI -

The Meca500 - smallest 6-axis-robot

2016

The Meca500 is the smallest six-axis industrial robot on the market. It weighs only 4.6 kg, and that's with its controller, which is embedded in the robot's base. The payload of the robot is 0.5 kg. And finally, the robot's repeatability is 5 micrometers.

Source

The Meca500 is the smallest six-axis industrial robot on the market. It weighs only 4.6 kg, and that's with its controller, which is embedded in the robot's base. The payload of the robot is 0.5 kg. And finally, the robot's repeatability is 5 micrometers.

Source -

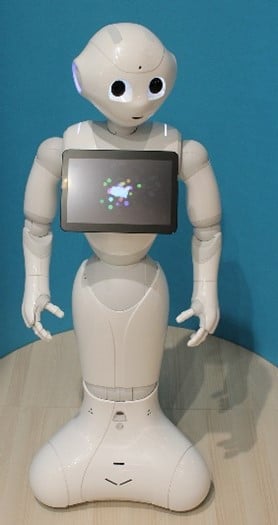

Softbank introduces Pepper

2014

Pepper was jointly developed by the French company Aldebaran Robotics SAS and the Japanese telecommunications and media group SoftBank Mobile Corp. It is the first humanoid social robot with the ability to recognize faces and basic human emotions through analysing facial expressions and tone of voice. It is currently employed at various shops, restaurants and other public spaces around the world. © photo Aldebaran

Pepper was jointly developed by the French company Aldebaran Robotics SAS and the Japanese telecommunications and media group SoftBank Mobile Corp. It is the first humanoid social robot with the ability to recognize faces and basic human emotions through analysing facial expressions and tone of voice. It is currently employed at various shops, restaurants and other public spaces around the world. © photo Aldebaran -

Precise Automation introduced the first collaborative SCARA robot

2013

The PF400 is a tabletop robot with an intrinsic safety system. It is opening up opportunities for laboratory automation, as it provides a small footprint and can be used without shields. Its four axis motion controller combines the advantages of bigger and more powerful controllers with a significantly lower prize and a small size and power profile required for laboratory uses. Source

The PF400 is a tabletop robot with an intrinsic safety system. It is opening up opportunities for laboratory automation, as it provides a small footprint and can be used without shields. Its four axis motion controller combines the advantages of bigger and more powerful controllers with a significantly lower prize and a small size and power profile required for laboratory uses. Source -

First Humanoid Robot in Space

2011

A Robonaut (R2B) launches up to the International Space Station. R2 is the first humanoid robot in space. Initially R2 was deployed on a fixed pedestal inside the ISS. Next steps include a leg for climbing through the corridors of the Space Station, upgrades for R2 to go outside into the vacuum of space.

source

A Robonaut (R2B) launches up to the International Space Station. R2 is the first humanoid robot in space. Initially R2 was deployed on a fixed pedestal inside the ISS. Next steps include a leg for climbing through the corridors of the Space Station, upgrades for R2 to go outside into the vacuum of space.

source -

KUKA (Germany) launched a new series of shelf-mounted robots (Quantec) with a new controller KR C4

2010

The Quantec K robots have an extremely low base, allowing a greater lower reach for unloading applications. The new KR C4 controller generation is the first to combine the complete safety controller in a single control system. This allows all tasks to be carried out at once.

source

The Quantec K robots have an extremely low base, allowing a greater lower reach for unloading applications. The new KR C4 controller generation is the first to combine the complete safety controller in a single control system. This allows all tasks to be carried out at once.

source -

Cyberdyne launches HAL, the first powered exoskeleton to support paraplegics

2009

HAL (Hybrid Assistive Limb) jointly was developed by Japan's Tsukuba University and the company Cyberdyne. It is a powered exoskeleton that is designed to support and expand the physical capabilities of its users, particularly people with physical disabilities. HAL 3 provides only leg function, HAL 5 is a full-body exoskeleton for the arms, legs, and torso. In 2013, HAL received global safety certification. Source image © Cyberdyne

HAL (Hybrid Assistive Limb) jointly was developed by Japan's Tsukuba University and the company Cyberdyne. It is a powered exoskeleton that is designed to support and expand the physical capabilities of its users, particularly people with physical disabilities. HAL 3 provides only leg function, HAL 5 is a full-body exoskeleton for the arms, legs, and torso. In 2013, HAL received global safety certification. Source image © Cyberdyne -

Release of ROS (Robot Operating System)

2009

Willow Garage releases the first version of ROS, an open source collection of software intended to reduce programming effort and propel the development of robot applications. ROS has quickly gained acceptance and has a growing community, which is supported by the Open Source Robotics Foundation (OSRF) and the ROS Industrial Consortium. ROS has a tremendous impact on the education of young roboticists and is widely spread in the academic world. Source

-

ABB, Sweden, launched the smallest multipurpose industrial robot, IRB120

2009

ABB's smallest ever multipurpose industrial robot weighs just 25kg and can handle a payload of 3kg (4kg for vertical wrist) with a reach of 580mm.

source

ABB's smallest ever multipurpose industrial robot weighs just 25kg and can handle a payload of 3kg (4kg for vertical wrist) with a reach of 580mm.

source -

Yaskawa Motoman, Japan, introduces control system to sync up to 8 robots

2009

Yaskawa Motoman, Japan, introduced the improved robot control system (DX100) which provided the fully synchronized control of eight robots, up to 72 axis. I/O devices and communication protocols. Dynamic interference zones protect robot arm and provide advanced collision avoidance.

source

Yaskawa Motoman, Japan, introduced the improved robot control system (DX100) which provided the fully synchronized control of eight robots, up to 72 axis. I/O devices and communication protocols. Dynamic interference zones protect robot arm and provide advanced collision avoidance.

source -

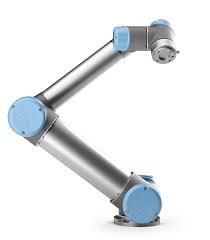

Universal Robots sold its first cobot

2008

The Danish company Universal Robots introduced UR5, a robot capable of safely operating alongside workers, eliminating the need for safety caging or fencing. UR5 was the first cost-efficient and user-friendly collaborative robot. It paved the way for the industry to target small and medium-sized manufacturers who had previously considered robotics too costly and complex. Source

The Danish company Universal Robots introduced UR5, a robot capable of safely operating alongside workers, eliminating the need for safety caging or fencing. UR5 was the first cost-efficient and user-friendly collaborative robot. It paved the way for the industry to target small and medium-sized manufacturers who had previously considered robotics too costly and complex. Source -

FANUC, Japan, launched a new heavy duty robot with a payload of almost 1,200kg

2008

"The M-2000iA is the world's largest and strongest six-axis robot," said Rich Meyer, product manager, Fanuc Robotics . "It has the longest reach and the strongest wrist surpassing all other six-axis robots available today. The wrist strength sets a record, but more importantly, allows our customers to move large heavy parts a great distance with maximum stability."

source

"The M-2000iA is the world's largest and strongest six-axis robot," said Rich Meyer, product manager, Fanuc Robotics . "It has the longest reach and the strongest wrist surpassing all other six-axis robots available today. The wrist strength sets a record, but more importantly, allows our customers to move large heavy parts a great distance with maximum stability."

source

-

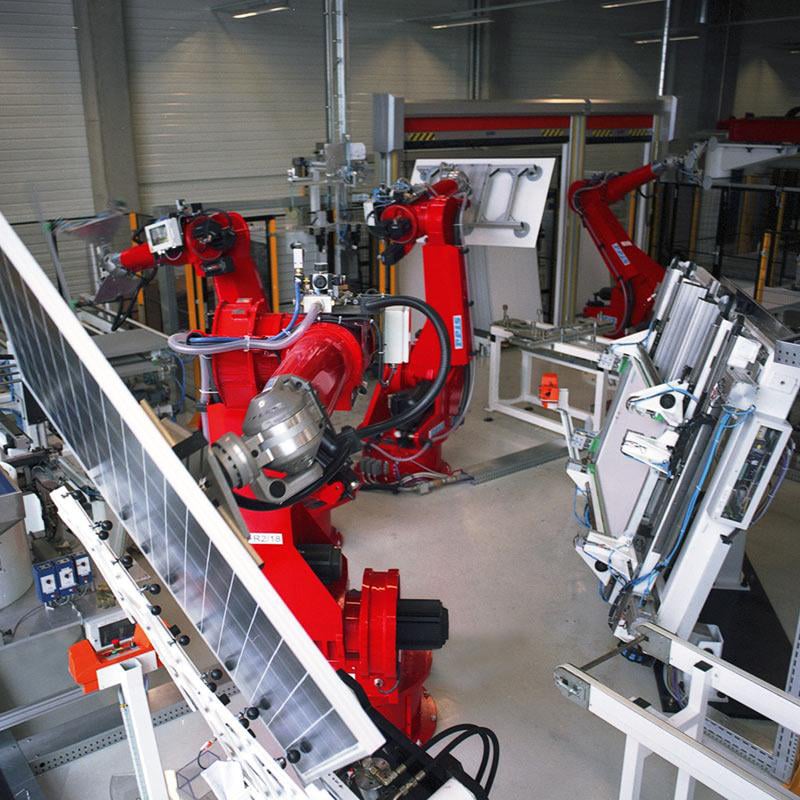

With the first systems realized in 2006, Reis Robotics became market leader for photovoltaic module production lines

2007

Since 2006 the new application field of photovoltaic became an important market for the use of robots

source

Since 2006 the new application field of photovoltaic became an important market for the use of robots

source -

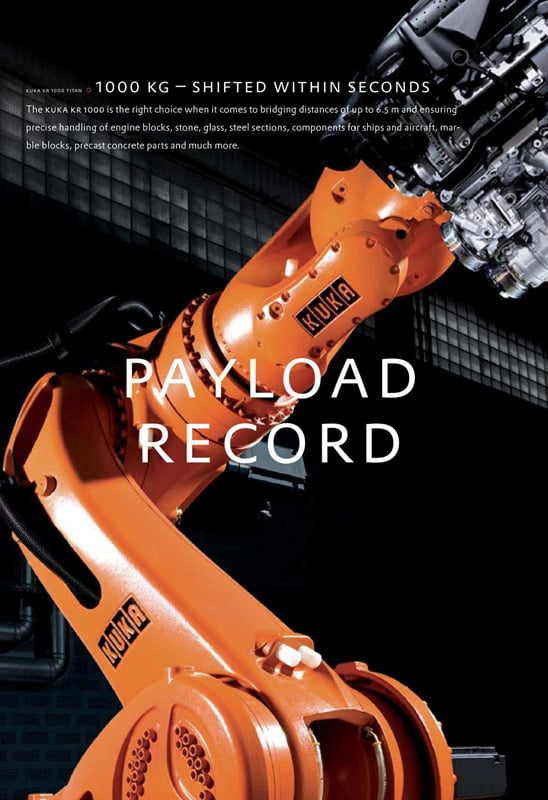

KUKA, Germany, launched the first long range robot and heavy duty robot with a payload of 1,000 kg

2007

It expands the application possibilities of industrial robots and creates a new class of reach and payload combinations

source

It expands the application possibilities of industrial robots and creates a new class of reach and payload combinations

source -

Motoman, Japan, launched super speed arc welding robots which reduces cycle times by 15%, the fastest welding robots in existence in 2007

2007

This speed is achieved with a 40% axis movement increase. Their design reduces air-cut time 30%.

source

This speed is achieved with a 40% axis movement increase. Their design reduces air-cut time 30%.

source -

Motoman, Japan, launched human sized single armed (7 axis) and dual armed robot (13 axis) with all of the supply cables hidden in the robot arm

2006

It significantly increases the robot's freedom of movement. Robots with dual robot arms, offering human-like flexibility in their movements, are ideal for machine tending and assembly - even beverage serving. The Robot Bar grabs national attention.

source

It significantly increases the robot's freedom of movement. Robots with dual robot arms, offering human-like flexibility in their movements, are ideal for machine tending and assembly - even beverage serving. The Robot Bar grabs national attention.

source -

KUKA, Germany presents the first Light Weight Robot

2006

Developed in cooperation with DLR, Institute of Robotics and Mechatronics, Germany, the outer structure of the KUKA lightweight robot is made of aluminum. It has a payload capacity of 7 kg and, thanks to its integrated sensors, is highly sensitive. This makes it ideally suited to handling and assembly tasks. Due to its low weight of just 16 kg - the first robot weighted two tons!, the robot is energy-efficient and portable and can perform a wide range of different tasks.

source

Developed in cooperation with DLR, Institute of Robotics and Mechatronics, Germany, the outer structure of the KUKA lightweight robot is made of aluminum. It has a payload capacity of 7 kg and, thanks to its integrated sensors, is highly sensitive. This makes it ideally suited to handling and assembly tasks. Due to its low weight of just 16 kg - the first robot weighted two tons!, the robot is energy-efficient and portable and can perform a wide range of different tasks.

source -

Comau, Italy, introduced the first Wireless Teach Pendant (WiTP)

2006

All the traditional data communication/robot programming activities can be carried out without the restrictions caused by the cable connected to the Control Unit, but at the same time absolute safety is ensured.

source

All the traditional data communication/robot programming activities can be carried out without the restrictions caused by the cable connected to the Control Unit, but at the same time absolute safety is ensured.

source

-

Kiva Systems presents the DU 1000 warehouse logistics robot

2005

Founded in 2003 as Distrobot System and soon renamed to Kiva Systems, the Drive Unit (DU) is a mobile robot that carries inventory shelves to human workers (instead of letting the worker go to the shelf) to pick items. The company and its technology were acquired by Amazon in 2012. Since then, Amazon uses the robot exclusively in their warehouses.

Photo: JOEL EDEN, Photography KIVA Systems

Founded in 2003 as Distrobot System and soon renamed to Kiva Systems, the Drive Unit (DU) is a mobile robot that carries inventory shelves to human workers (instead of letting the worker go to the shelf) to pick items. The company and its technology were acquired by Amazon in 2012. Since then, Amazon uses the robot exclusively in their warehouses.

Photo: JOEL EDEN, Photography KIVA Systems -

Motoman, Japan, introduced the improved robot control system 〈NX100〉 which provided the synchronized control of four robots, up to 38 axis

2004

The NX100 programming pendant has a touch screen display and is based on WindowsCE operative system

source

The NX100 programming pendant has a touch screen display and is based on WindowsCE operative system

source -

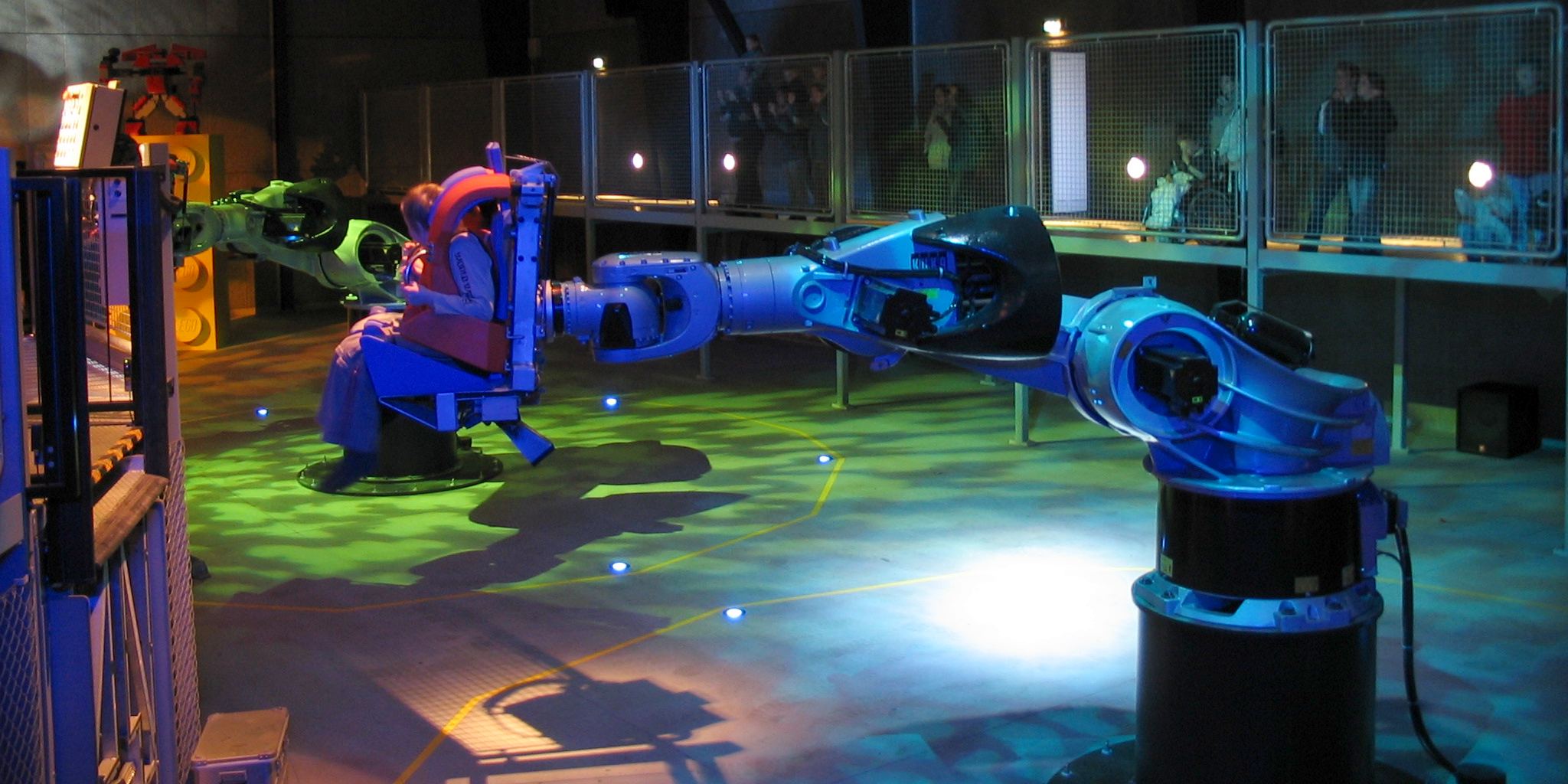

Robocoaster, the first entertainment robot based on an articulated robot by KUKA, Germany

2003

KUKA is the first robot manufacturer to bring people and robots into close contact: in the Robocoaster, the robot whirls passengers around in the air - an extraordinary entertainment ride for amusement parks and events.

source

KUKA is the first robot manufacturer to bring people and robots into close contact: in the Robocoaster, the robot whirls passengers around in the air - an extraordinary entertainment ride for amusement parks and events.

source -

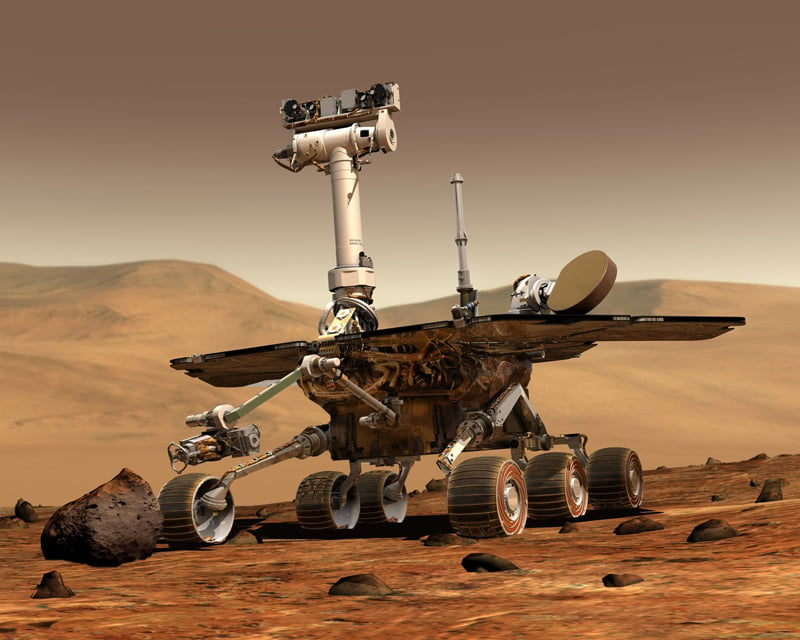

Robots go to Mars

2003

Mars Exploration Rover Mission is an ongoing robotic space mission involving two rovers, Spirit and Opportunity, exploring the planet Mars. It began in 2003 with the sending of the two rovers to explore the Martian surface and geology.

source

Mars Exploration Rover Mission is an ongoing robotic space mission involving two rovers, Spirit and Opportunity, exploring the planet Mars. It began in 2003 with the sending of the two rovers to explore the Martian surface and geology.

source -

Roomba - the first domestically available robot vacuum cleaner

2002

Roomba (developed and commercialized by iRobot) was the first commercially available autonomous vacuum cleaner. It could detect dirty spots on the floor and avoid obstacles and stairs and returned to its charging dock when finished.

image © 2006 Larry D. Moore, CC BY-SA 4.0

Roomba (developed and commercialized by iRobot) was the first commercially available autonomous vacuum cleaner. It could detect dirty spots on the floor and avoid obstacles and stairs and returned to its charging dock when finished.

image © 2006 Larry D. Moore, CC BY-SA 4.0 -

Intuitive Surgical commercialized Da Vinci surgical robot

1999

The da Vinci is a surgical robot designed for minimally invasive procedures. It has four arms equipped with surgical instruments and cameras that a physician controls remotely from a console. Source image © Intuitive Surgical

The da Vinci is a surgical robot designed for minimally invasive procedures. It has four arms equipped with surgical instruments and cameras that a physician controls remotely from a console. Source image © Intuitive Surgical -

Reis introduces integrated laser beam guiding within the robot arm

1999

Reis Robotics receives patent on the integrated laser beam guiding through the robot arm and launches the RV6L-CO2 laser robot model. This technology replaces the need of an external beam guiding device thus allowing to use laser in combination with a robot at high dynamics and no collision contours

source

Reis Robotics receives patent on the integrated laser beam guiding through the robot arm and launches the RV6L-CO2 laser robot model. This technology replaces the need of an external beam guiding device thus allowing to use laser in combination with a robot at high dynamics and no collision contours

source -

First remote diagnosis for robots via Internet by KUKA, Germany

1999

-

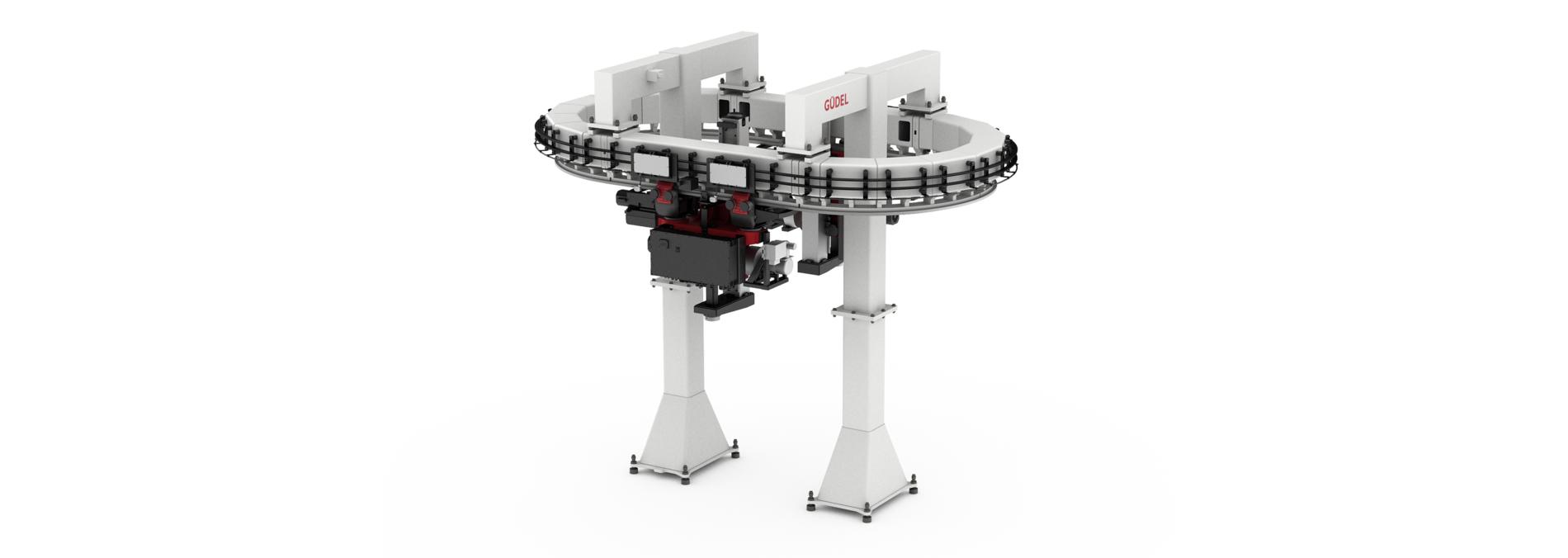

Güdel, Switzerland, launched the “roboLoop” system, the only curved-track gantry and transfer system

1998

The roboLoop concept enables one or more robo-carriers to track curves and to circulate in a closed system, thereby creating new possibilities for factory automation.

source

The roboLoop concept enables one or more robo-carriers to track curves and to circulate in a closed system, thereby creating new possibilities for factory automation.

source

-

ABB, Sweden, developed the FlexPicker, the world’s fastest picking robot based on the delta robot developed by Reymond Clavel, Federal Institute of Technology of Lausanne (EPFL)

1998

It was able to pick 120 objects a minute or pick and release at a speed of 10 meters per second, using image technology.

source

It was able to pick 120 objects a minute or pick and release at a speed of 10 meters per second, using image technology.

source

-

Reis Robotics launches the 5. robot control generation ROBOTstar V, with one of the shortest interpolation cycle times for robot controls

1998

Reis Robotics launches the 5. robot control generation ROBOTstar V, with one of the shortest interpolation cycle times for robot controls source

-

KUKA, Germany, launched the first PC-based robot control system

1996

It was possible, for the first time, to move robots in real time using a 6D mouse on an operator control device. This teach pendant featured a Windows user interface for control and programming tasks.

source

It was possible, for the first time, to move robots in real time using a 6D mouse on an operator control device. This teach pendant featured a Windows user interface for control and programming tasks.

source -

Motoman introduced the first robot control system 〈MRC〉 which provided the synchronized control of two robots

1994

MRC also made it possible to edit robot jobs from an ordinary PC. MRC offered the ability to control up to 21 axes. It could also synchronize the motions of two robots.

source

MRC also made it possible to edit robot jobs from an ordinary PC. MRC offered the ability to control up to 21 axes. It could also synchronize the motions of two robots.

source -

Demaurex, Switzerland, sold its first Delta robot packaging application to Roland

1992

The first application was a landmark installation of 6 robots loading pretzels into blister trays. It was based on the delta robot developed by Reymond Clavel, Federal Institute of Technology of Lausanne (EPFL).

source

The first application was a landmark installation of 6 robots loading pretzels into blister trays. It was based on the delta robot developed by Reymond Clavel, Federal Institute of Technology of Lausanne (EPFL).

source -

ABB, Sweden, launched an open control system 〈S4〉

1992

The S4 controller was designed to improve two areas of critical importance to the user; the man-machine interface and the robot's technical performance.

source

The S4 controller was designed to improve two areas of critical importance to the user; the man-machine interface and the robot's technical performance.

source

-

Wittmann, Austria introduced the CAN-Bus control for robots

1992

"In practical terms, these features can add up to faster operations for robot workcells, which is why Wittmann Robot and Automation Systems Inc. of Torrington, Conn., adopted CANbus for all its CNC robots 18 months ago. Sales manager Ken Heyse explains that Wittmann's previous CNC controller, which used a single microprocessor for all robot and peripheral functions, had to perform various subroutines sequentially, potentially interrupting the operation of the robot. CANbus, by contrast, handles data locally. The robot itself, its pendant, stackers, and other downstream equipment all process data in their own microprocessors. Only then does a master controller coordinate all those efforts. In Wittmann's CANbus CNC controls, all the robot programs and related subroutines run simultaneously on the different microprocessors. The result, Heyse says, is a speedier workcell." source

-

The first AMR to be used in a hospital

1988

One of the first autonomous mobile robots (AMR) - a robot that can plan and execute its own path to its destination - was developed by Joseph Engelberger’s company Transitions Research Corporation (later renamed HelpMate Robotics Inc). The robot called Helpmate was used as a courier to transport objects within hospitals. The first one was purchased and deployed by a hospital in Danbury, Connecticut (USA), but the robot was soon used in more than 100 different hospitals around the world. image © Kaluga.2012 (scan from print), CC BY-SA 3.0, via Wikimedia Commons

One of the first autonomous mobile robots (AMR) - a robot that can plan and execute its own path to its destination - was developed by Joseph Engelberger’s company Transitions Research Corporation (later renamed HelpMate Robotics Inc). The robot called Helpmate was used as a courier to transport objects within hospitals. The first one was purchased and deployed by a hospital in Danbury, Connecticut (USA), but the robot was soon used in more than 100 different hospitals around the world. image © Kaluga.2012 (scan from print), CC BY-SA 3.0, via Wikimedia Commons -

ABB, Sweden produced the fastest assembly robot (IRB 1000)

1984

It was equipped with a vertical arm, a sort of hanging pendulum robot. The robot could work quickly across a large area without the need to traverse. It was as much as 50% faster than conventional arm robots. (Lars Westerlund, The Extended Arm of Man)

source

It was equipped with a vertical arm, a sort of hanging pendulum robot. The robot could work quickly across a large area without the need to traverse. It was as much as 50% faster than conventional arm robots. (Lars Westerlund, The Extended Arm of Man)

source -

Adept, USA, introduced the AdeptOne, first direct-drive SCARA robot

1984

Electric-drive motors connected directly to the arms eliminating the need for intermediate gear or chain system. The simplicity of the mechanism made AdeptOne robots very robust in continuous industrial automation applications, while maintaining high accuracy.

source

Electric-drive motors connected directly to the arms eliminating the need for intermediate gear or chain system. The simplicity of the mechanism made AdeptOne robots very robust in continuous industrial automation applications, while maintaining high accuracy.

source -

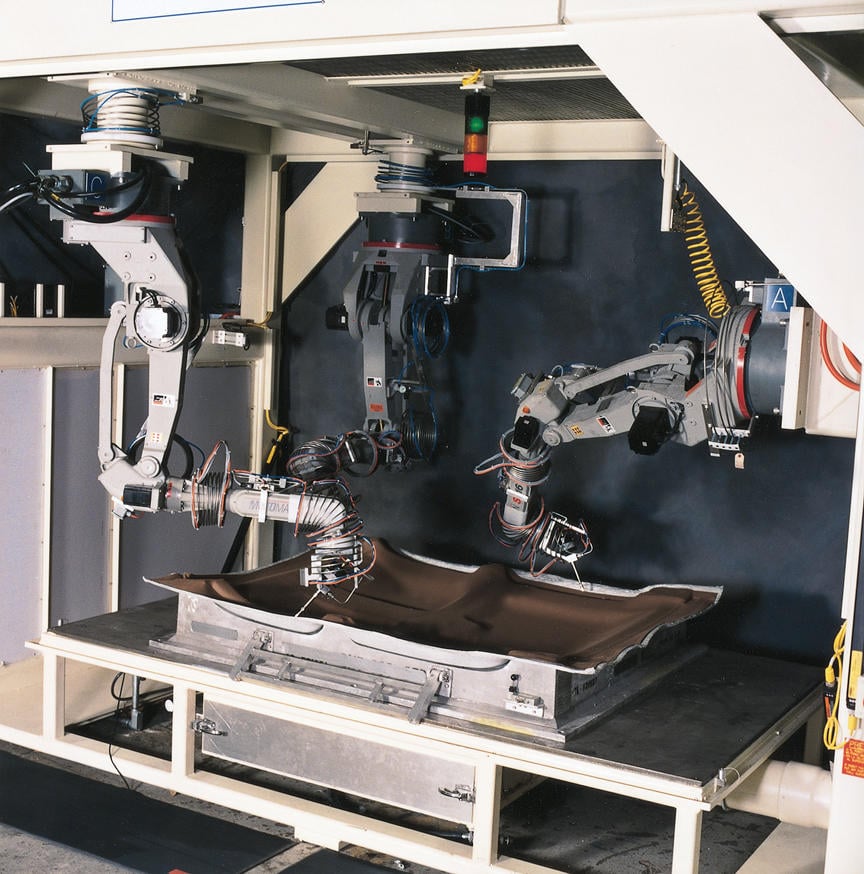

Flexible Automated Assembly Lines

1983

Westinghouse issues a research report on APAS, or adaptable-programming assembly systems, a pilot project for using robots in a more flexible automated assembly line environment. The approach uses machine vision in the positioning, orienting and inspection of the component parts. source

-

IBM develops a programming language for robotics, AML

1982

AML (A Manufacturing Language), a powerful, easily used programming language was developed by IBM, USA, specifically for robotic applications. Using an IBM Personal Computer manufacturing engineers could quickly and easily create application programs.

source

AML (A Manufacturing Language), a powerful, easily used programming language was developed by IBM, USA, specifically for robotic applications. Using an IBM Personal Computer manufacturing engineers could quickly and easily create application programs.

source -

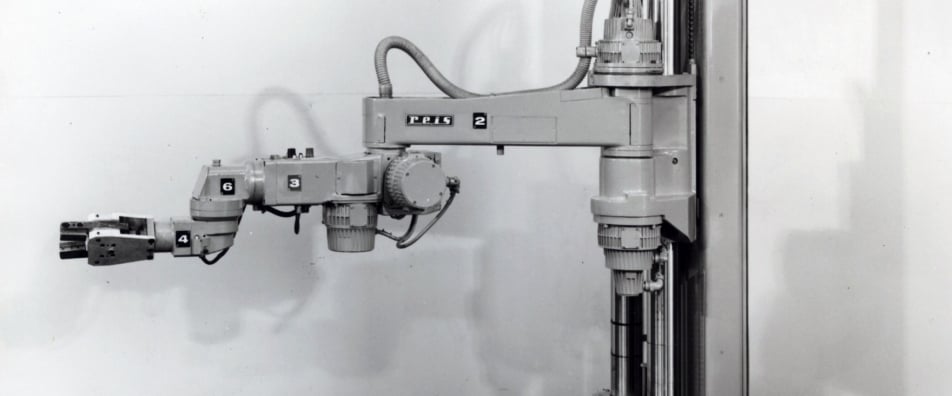

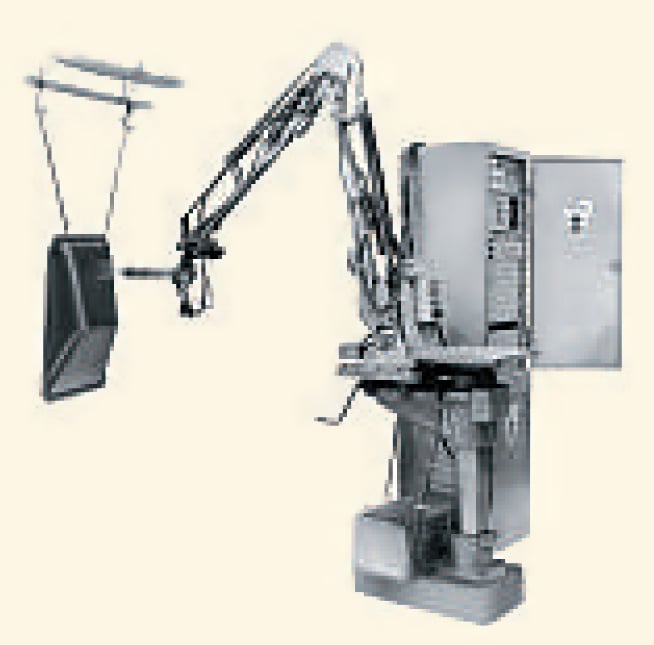

PaR Systems, USA, introduced its first industrial gantry robot

1981

Gantry robots provided a much larger range of motion than pedestal robots of the day, and could replace several robots. (PaR 50th Anniversary, 2010).

source

Gantry robots provided a much larger range of motion than pedestal robots of the day, and could replace several robots. (PaR 50th Anniversary, 2010).

source -

GM installed “CONSIGHT”, a machine vision system

1981

source The first production implementation of the General Motors Consight vision system at the St. Catherines, Ontario, foundry is successfully sorting up to six different castings at up to 1,400 an hour from a belt conveyor using three industrial robots in a harsh manufacturing environment.

The first production implementation of the General Motors Consight vision system at the St. Catherines, Ontario, foundry is successfully sorting up to six different castings at up to 1,400 an hour from a belt conveyor using three industrial robots in a harsh manufacturing environment. -

First use of machine vision

1980

At the University of Rhode Island, USA, a bin-picking robotics system demonstrated the picking of parts in random orientation and positions out of a bin.

-

Nachi, Japan, developed the first motor-driven robots

1979

The spot-welding robots ushered in a new era of electric driven robots, replacing the previous era of hydraulic drive.

source

The spot-welding robots ushered in a new era of electric driven robots, replacing the previous era of hydraulic drive.

source -

First six-axis robot with own control system RE 15 by Reis, Obernburg, Germany

1979

-

Hiroshi Makino, University of Yamanashi, Japan, developed the SCARA-Robot (Selective Compliance Assembly Robot Arm)

1978

By virtue of the SCARA's parallel-axis joint layout, the arm is slightly compliant in the X-Y direction but rigid in the 'Z' direction, hence the term: Selective Compliant. This is advantageous for many types of assembly operations, i.e., inserting a round pin in a round hole without binding. The second attribute of the SCARA is the jointed two-link arm layout similar to our human arms, hence the often-used term, Articulated. This feature allows the arm to extend into confined areas and then retract or "fold up" out of the way. This is advantageous for transferring parts from one cell to another or for loading/ unloading process stations that are enclosed. In 1981, SCARA robots were launched by by Sankyo Seiki, Japan and Hirata, Japan. source

-

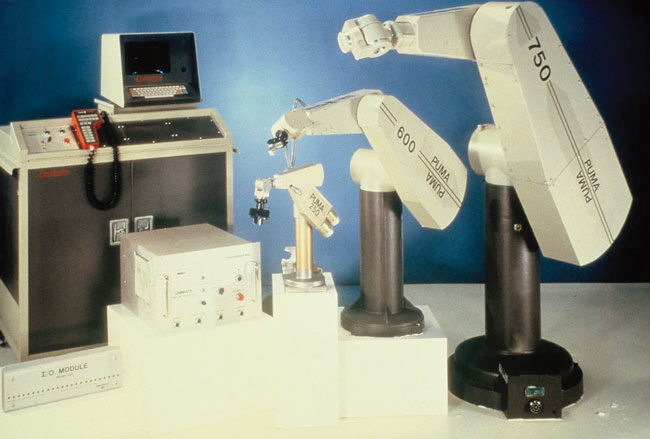

Programmable Universal Machine for Assembly (PUMA) was developed by Unimation/Vicarm; USA, with support from General Motors

1978

GM had concluded that 90 percent of all parts handled during assembly weighed five pounds or less. The PUMA was adapted to GM specifications for a small parts handling line robot that maintained the same space intrusion of a human operator.

GM had concluded that 90 percent of all parts handled during assembly weighed five pounds or less. The PUMA was adapted to GM specifications for a small parts handling line robot that maintained the same space intrusion of a human operator. -

Hitachi (Japan) developed an assembly cell to assemble vacuum cleaners with 8 TV cameras and two robot arms

1977

-

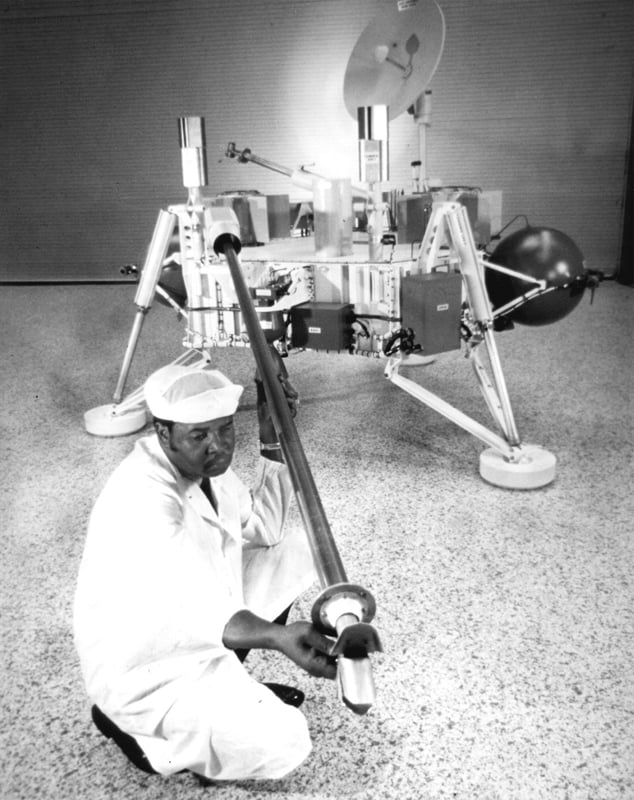

Robots in space

1976

Robot arms are used on Viking 1 and 2 space probes.

source

Robot arms are used on Viking 1 and 2 space probes.

source -

Hitachi (Japan) developed the first sensor based arc welding robot “Mr. AROS”

1975

The robot is equipped with microprocessors and gap sensors to correct arc welding path by detecting precise location of workpieces. source

The robot is equipped with microprocessors and gap sensors to correct arc welding path by detecting precise location of workpieces. source -

ABB developed an industrial robot with a payload up to 60 kg

1975

This met the demand of the automotive industry for more payload, more flexibility. The robot, called the IRB60, was first delivered to Saab in Sweden for welding car bodies.

source

This met the demand of the automotive industry for more payload, more flexibility. The robot, called the IRB60, was first delivered to Saab in Sweden for welding car bodies.

source -

The Olivetti “SIGMA” a cartesian-coordinate robot, is one of the first used in assembly applications

1975

The Olivetti SIGMA robot was used in Italy for assembly operations with two hands.

source

The Olivetti SIGMA robot was used in Italy for assembly operations with two hands.

source -

Hitachi (Japan) developed the first precision insertion control robot “HI-T-HAND Expert”

1974

This robot had a flexible wrist mechanism and a force feed-back control system. Therefore it could insert mechanical parts with a clearance of about 10 micron.

This robot had a flexible wrist mechanism and a force feed-back control system. Therefore it could insert mechanical parts with a clearance of about 10 micron. -

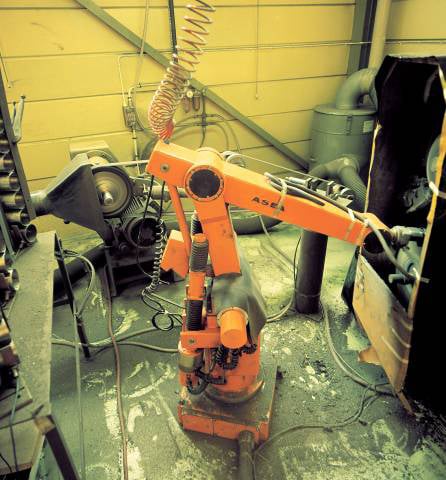

The first fully electric, microprocessor-controlled industrial robot, IRB 6 from ASEA

1974

With anthropomorphic design, its arm movement mimicked that of a human arm, with a payload of 6kg and 5 axis. The S1 controller was the first to use a intel 8 bit microprocessor. The memory capacity was 16KB. The controller had 16 digital I/O and was programmed trough 16 keys and a four digit LED display. The first model, IRB 6, was developed in 1972-1973 on assignment by the ASEA CEO Curt Nicolin and was shown for the first time at the end of August 1973. It was acquired by Magnussons in Genarp to wax and polish stainless steel tubes bent at 90° angles.

source

With anthropomorphic design, its arm movement mimicked that of a human arm, with a payload of 6kg and 5 axis. The S1 controller was the first to use a intel 8 bit microprocessor. The memory capacity was 16KB. The controller had 16 digital I/O and was programmed trough 16 keys and a four digit LED display. The first model, IRB 6, was developed in 1972-1973 on assignment by the ASEA CEO Curt Nicolin and was shown for the first time at the end of August 1973. It was acquired by Magnussons in Genarp to wax and polish stainless steel tubes bent at 90° angles.

source

-

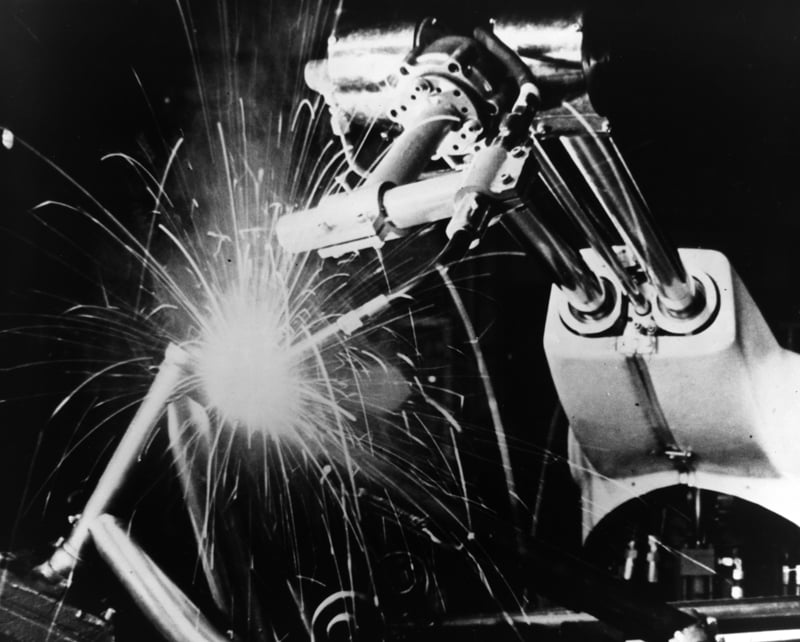

The first arc welding robots go to work in Japan

1974

In Japan, Kawasaki built on the Unimate design to create an arc-welding robot, used to fabricate their motorcycle frames. They also developed touch and force-sensing capabilities in their Hi-T-Hand robot, enabling the robot to guide pins into holes at a rate of one second per pin.

source

In Japan, Kawasaki built on the Unimate design to create an arc-welding robot, used to fabricate their motorcycle frames. They also developed touch and force-sensing capabilities in their Hi-T-Hand robot, enabling the robot to guide pins into holes at a rate of one second per pin.

source -

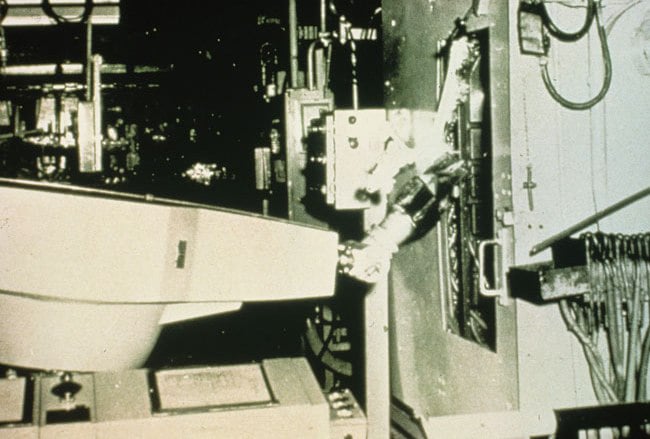

The first minicomputer-controlled industrial robot comes to market

1974

The first commercially available minicomputer-controlled industrial robot was developed by Richard Hohn for Cincinnati Milacron Corporation. The robot was called the T3, The Tomorrow Tool.

The first commercially available minicomputer-controlled industrial robot was developed by Richard Hohn for Cincinnati Milacron Corporation. The robot was called the T3, The Tomorrow Tool. -

Hitachi (Japan) developed the automatic bolting robot for concrete pile and pole industry

1973

This robot was the first industrial robot with dynamic vision sensors for moving objects. It recognized bolts on a mold while it is moving and fastened/loosened the bolts in synchronization with the mold motion.

This robot was the first industrial robot with dynamic vision sensors for moving objects. It recognized bolts on a mold while it is moving and fastened/loosened the bolts in synchronization with the mold motion. -

Scheinemann started production of Vicarm/Stanford arm at Vicarm Inc, USA

1973

The Stanford arm was a robotic arm that performed small-parts assembly using feedback from touch and pressure sensors. Professor Scheinman, the developer of the Stanford Arm, formed Vicarm Inc. to market a version of the arm for industrial applications. The new arm was controlled by a minicomputer.

The Stanford arm was a robotic arm that performed small-parts assembly using feedback from touch and pressure sensors. Professor Scheinman, the developer of the Stanford Arm, formed Vicarm Inc. to market a version of the arm for industrial applications. The new arm was controlled by a minicomputer. -

First robot to have six electromechanically driven axes

1973

KUKA moves from using Unimate robots to developing their own robots. Their robot, the Famulus was the first robot to have six electromechanically driven axes.

source

KUKA moves from using Unimate robots to developing their own robots. Their robot, the Famulus was the first robot to have six electromechanically driven axes.

source -

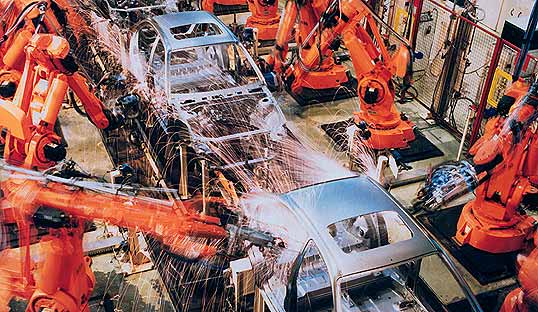

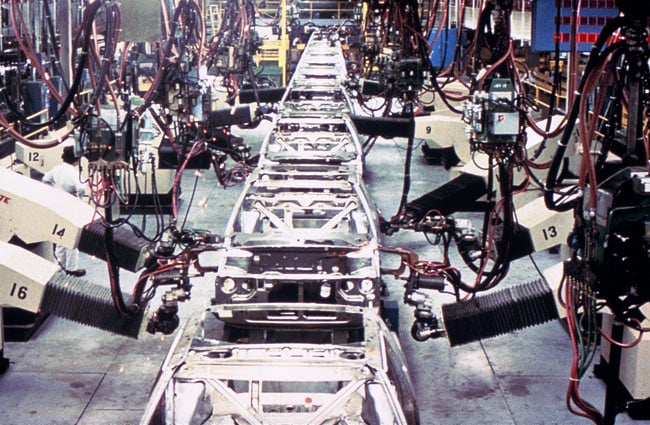

Robot production lines installed in Europe

1972

FIAT in Italy and Nissan in Japan installed production lines of spot-welding robots.

source

FIAT in Italy and Nissan in Japan installed production lines of spot-welding robots.

source -

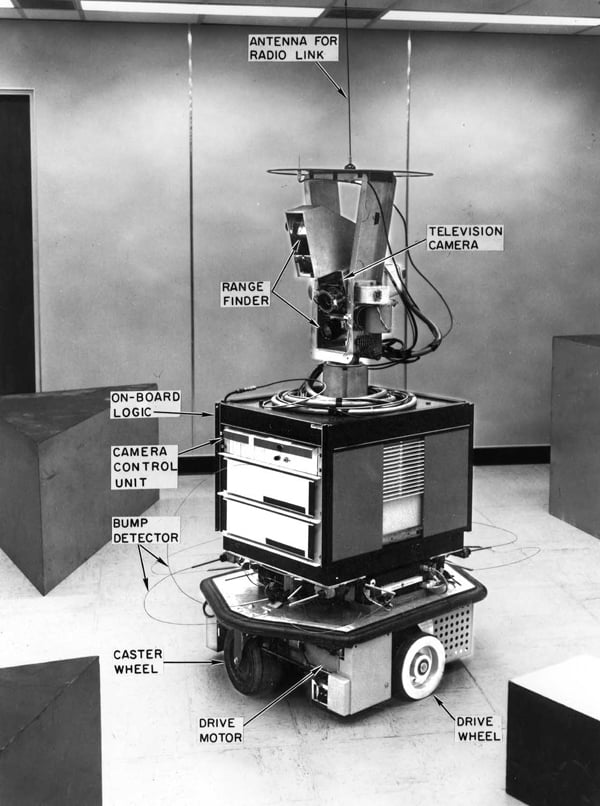

Robot vision, for mobile robot guidance, is demonstrated at the SRI with Shakey

1972

Robot vision, for mobile robot guidance, is demonstrated at the Stanford Research Institute (SRI). Shakey the robot was developed at the Artificial Intelligence Center of SRI between 1966 and 1972. It was the first robot capable of intelligently navigating its environment with robot vision and helped to lay the groundwork for today’s Autonomous Mobile Robots (AMR). It was also the first robot to use artificial intelligence. Shakey itself remained a research tool and never was commercialized. © Photo SRI International Source

Robot vision, for mobile robot guidance, is demonstrated at the Stanford Research Institute (SRI). Shakey the robot was developed at the Artificial Intelligence Center of SRI between 1966 and 1972. It was the first robot capable of intelligently navigating its environment with robot vision and helped to lay the groundwork for today’s Autonomous Mobile Robots (AMR). It was also the first robot to use artificial intelligence. Shakey itself remained a research tool and never was commercialized. © Photo SRI International Source -

The Japanese Robot Association (JIRA, later JARA) was established

1971

This was the first national robot association. The Japan Robot Association was formed in 1971 as the Industrial Robot Conversazione, a voluntary organization. The Conversazione was reorganized into the Japan Industrial Robot Association (JIRA) in 1972, and the Association was formally incorporated in 1973. source

-

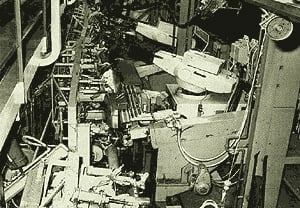

First production line with hydraulic actuated robots at Daimler Benz, Sindelfingen

1971

For Daimler-Benz, KUKA builds Europe's first welding transfer line with robots in 1971.

source

For Daimler-Benz, KUKA builds Europe's first welding transfer line with robots in 1971.

source -

Hitachi (Japan) developed the world’s first vision-based fully-automatic intelligent robot that assembles objects from plan drawings

1969

The robot could build blocks based on information created from a direct visual image of assembly plan drawings.

The robot could build blocks based on information created from a direct visual image of assembly plan drawings. -

Unimate robots enter Japanese market

1969

Unimation signs a licensing agreement with Kawasaki Heavy Industries to manufacture and market Unimate robots for the Asian market. Kawasaki regarded the development and production of labor-saving machines and systems as an important mission, and became Japan's pioneer in the industrial robot field. In 1969, the company succeeded in developing the Kawasaki-Unimate 2000, the first industrial robot ever produced in Japan.

source

Unimation signs a licensing agreement with Kawasaki Heavy Industries to manufacture and market Unimate robots for the Asian market. Kawasaki regarded the development and production of labor-saving machines and systems as an important mission, and became Japan's pioneer in the industrial robot field. In 1969, the company succeeded in developing the Kawasaki-Unimate 2000, the first industrial robot ever produced in Japan.

source -

Trallfa, Norway, offers the first commercial painting robot

1969

The robots were developed for in-house use in 1967 to spray paint wheelbarrows during a Norwegian labor shortage.

source

The robots were developed for in-house use in 1967 to spray paint wheelbarrows during a Norwegian labor shortage.

source -

GM installed the first spot-welding robots at its Lordstown assembly plant

1969

The Unimation robots boosted productivity and allowed more than 90 percent of body welding operations to be automated vs. only 20 percent to 40 percent at traditional plants, where welding was a manual, dirty and dangerous task dominated by large jigs and fixtures.

source

The Unimation robots boosted productivity and allowed more than 90 percent of body welding operations to be automated vs. only 20 percent to 40 percent at traditional plants, where welding was a manual, dirty and dangerous task dominated by large jigs and fixtures.

source -

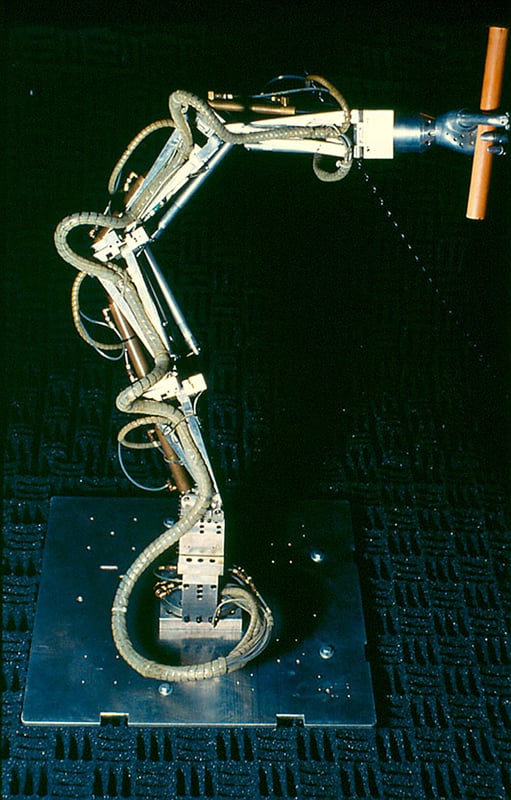

The octopus-like Tentacle Arm was developed by Marvin Minsky

1968

The octopus-like Tentacle Arm was developed by Marvin Minsky

source

The octopus-like Tentacle Arm was developed by Marvin Minsky

source -

The first industrial robot sold in Europe

1967

The first industrial robot sold in Europe, a Unimate, was installed at Metallverken, Uppsland Väsby, Sweden

The first industrial robot sold in Europe, a Unimate, was installed at Metallverken, Uppsland Väsby, Sweden -

The first cylindrical robot, the Versatran from AMF

1962

6 Versatran robots were installed by American Machine and Foundry (AMF) at the Ford factory in Canton, USA. It was named the Versatran from the words "versatile transfer".

source

6 Versatran robots were installed by American Machine and Foundry (AMF) at the Ford factory in Canton, USA. It was named the Versatran from the words "versatile transfer".

source

-

Unimation installed the first industrial robot at GM

1961

The world's first industrial was robot used on a production line at the GM Ternstedt plant in Trenton, NJ, which made door and window handles, gearshift knobs, light fixtures and other hardware for automotive interiors. Obeying step-by-step commands stored on a magnetic drum, the Unimate robot's 4,000 pound arm sequenced and stacked hot pieces of diecast metal. The robot cost US$ 65,000 to make but Unimation sold it for US $18,000.

The world's first industrial was robot used on a production line at the GM Ternstedt plant in Trenton, NJ, which made door and window handles, gearshift knobs, light fixtures and other hardware for automotive interiors. Obeying step-by-step commands stored on a magnetic drum, the Unimate robot's 4,000 pound arm sequenced and stacked hot pieces of diecast metal. The robot cost US$ 65,000 to make but Unimation sold it for US $18,000. -

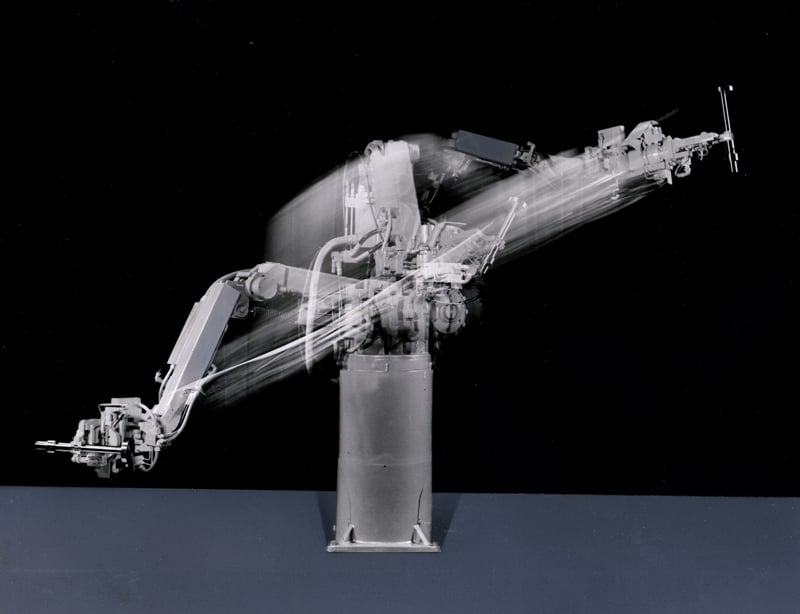

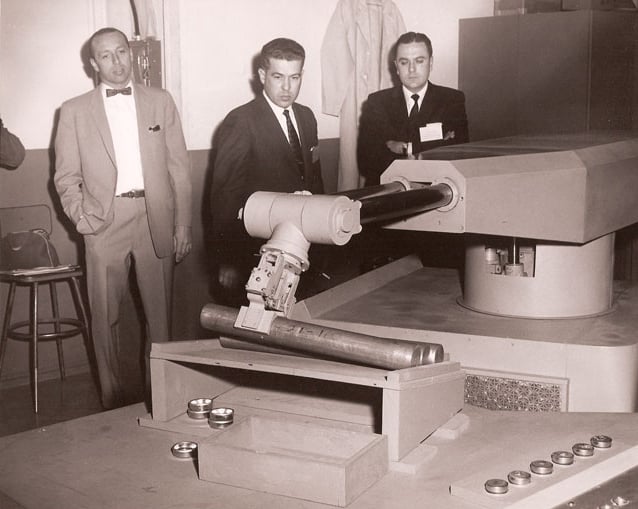

Development of the first industrial robot by George Devol and Joseph Engelberger

1959

It weighed two tons and was controlled by a program on a magnetic drum. They used hydraulic actuators and were programmed in joint coordinates, i.e. the angles of the various joints were stored during a teaching phase and replayed in operation. They were accurate to within 1/10,000 of an inch.

It weighed two tons and was controlled by a program on a magnetic drum. They used hydraulic actuators and were programmed in joint coordinates, i.e. the angles of the various joints were stored during a teaching phase and replayed in operation. They were accurate to within 1/10,000 of an inch.

IFR Secretariat

The General Secretariat is responsible for the daily management of IFR and the coordination of all major activities, events and collaboration. The General Secretariat handles all questions regarding IFR membership.

Dr. Susanne Bieller

IFR General Secretary

Phone: +49 69-6603-1502

E-Mail: secretariat(at)ifr.org

Silke Lampe

Communication Manager

Phone: +49 69-6603-1697

E-Mail: secretariat(at)ifr.org

Credits · Legal Disclaimer · Privacy Policy ·World Robotics Terms of Usage · © IFR 2026