Quality control

© KUKA

Sensitive joint torque sensors in all six axes of the LBR iisy enable safe cooperation be-tween humans and robots.

Hospital logistics

© OPPENT

OPPENT EVO Cart mobile robots transporting materials in a hospital, driven by BlueBotics ANT® navigation technology.

Internal Logistic with forklift

© Stoecklin Logistick AG

Eagle-Ant 1 automated forklifts by Stoecklin Logistick AG in operation at a food production plant.

High Payload Transportation

© Stäubli

AGV with a high payload moves automatically 20 tons at once.

Internal Logistics with forklift

© Stäubli

The ultra-compact forklift AGV transports pallets and increases productivity at an automotive OEM.

Logistics

© Mech-Mind

The robot picks and places boxes on palettes.

Material Handling

© ABB

BlueBotics mini™ mobile robots in operation at ABB’s semiconductor manufacturing plant in Lenzburg, Switzerland.

Picking Cosmetics

© FANUC

FANUC robot picking in cosmetics industry by using vision systems.

Picking Cosmetics

© FANUC

FANUC robot picking in cosmetics industry by using vision systems.

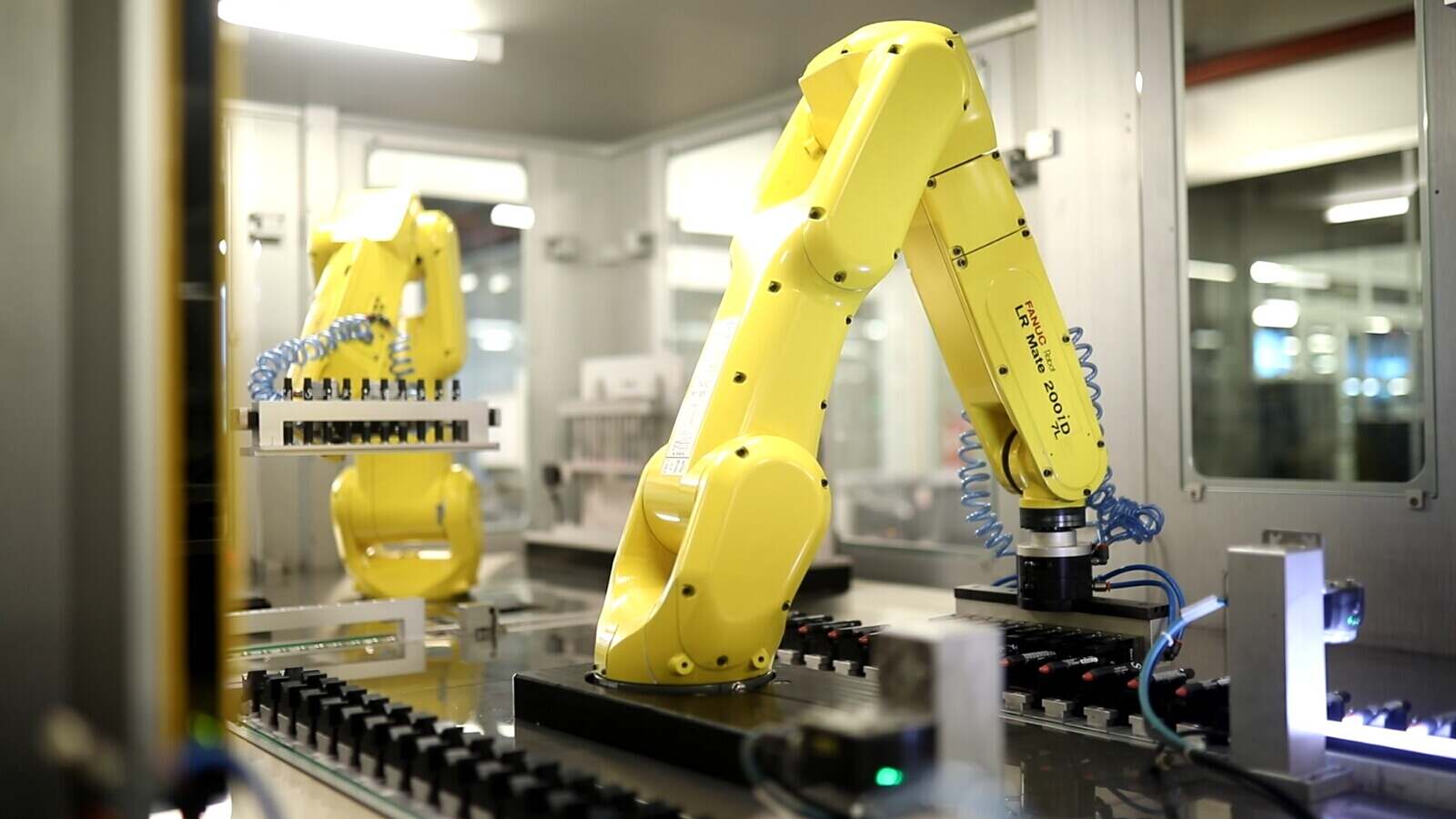

Material Handling

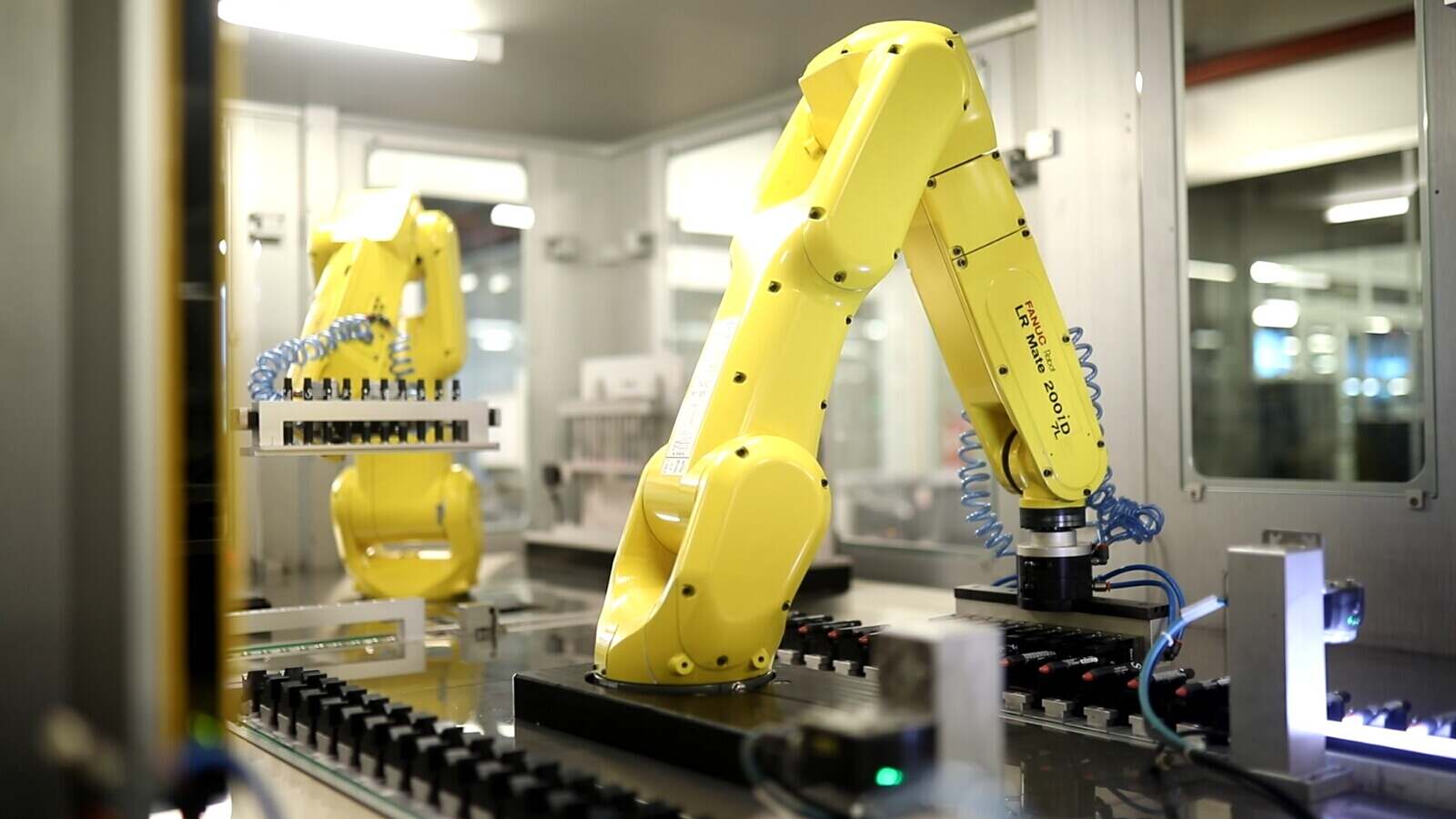

© FANUC

Two FANUC LR Mate 200iD-7L robots handle parts between them.

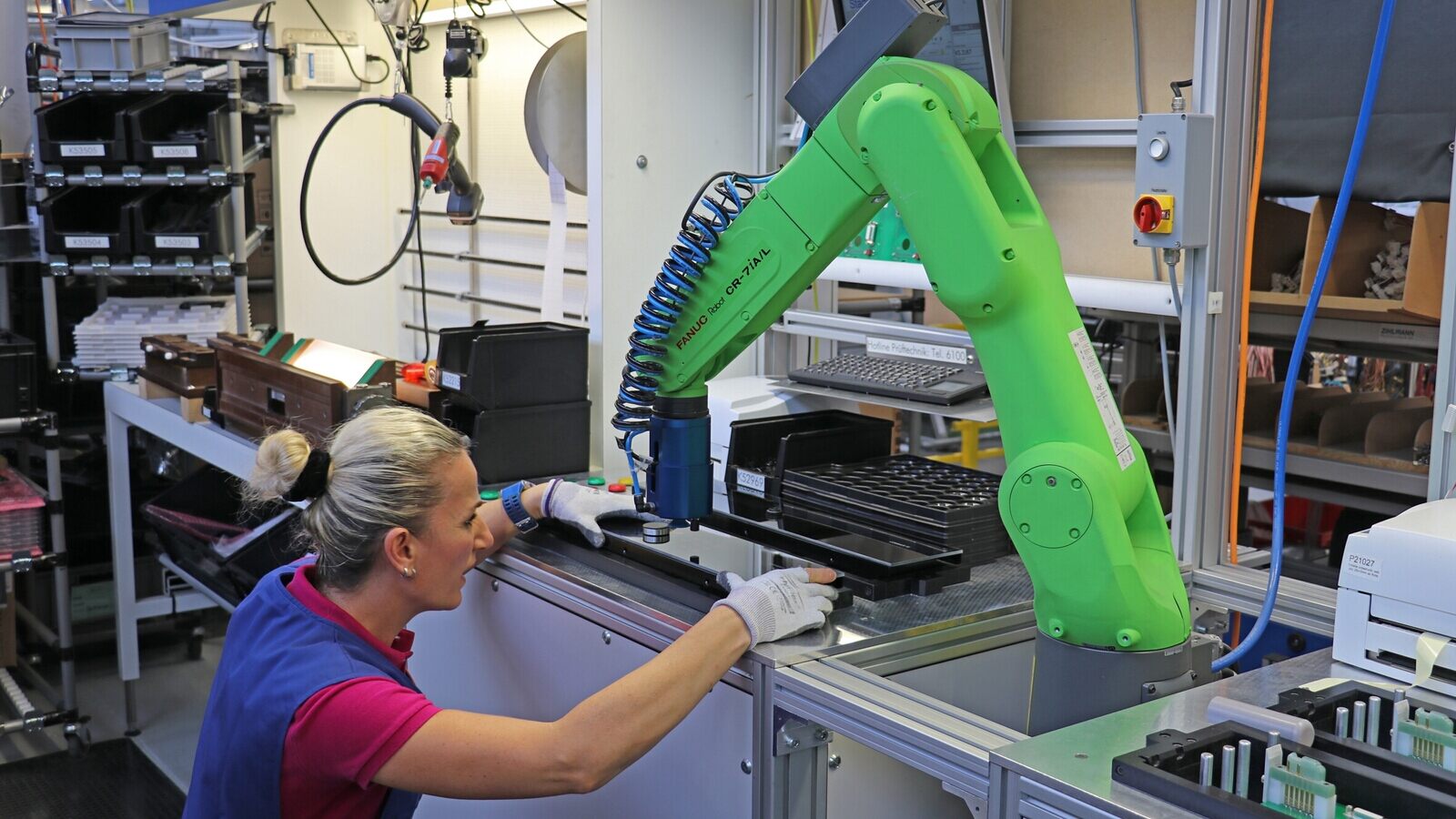

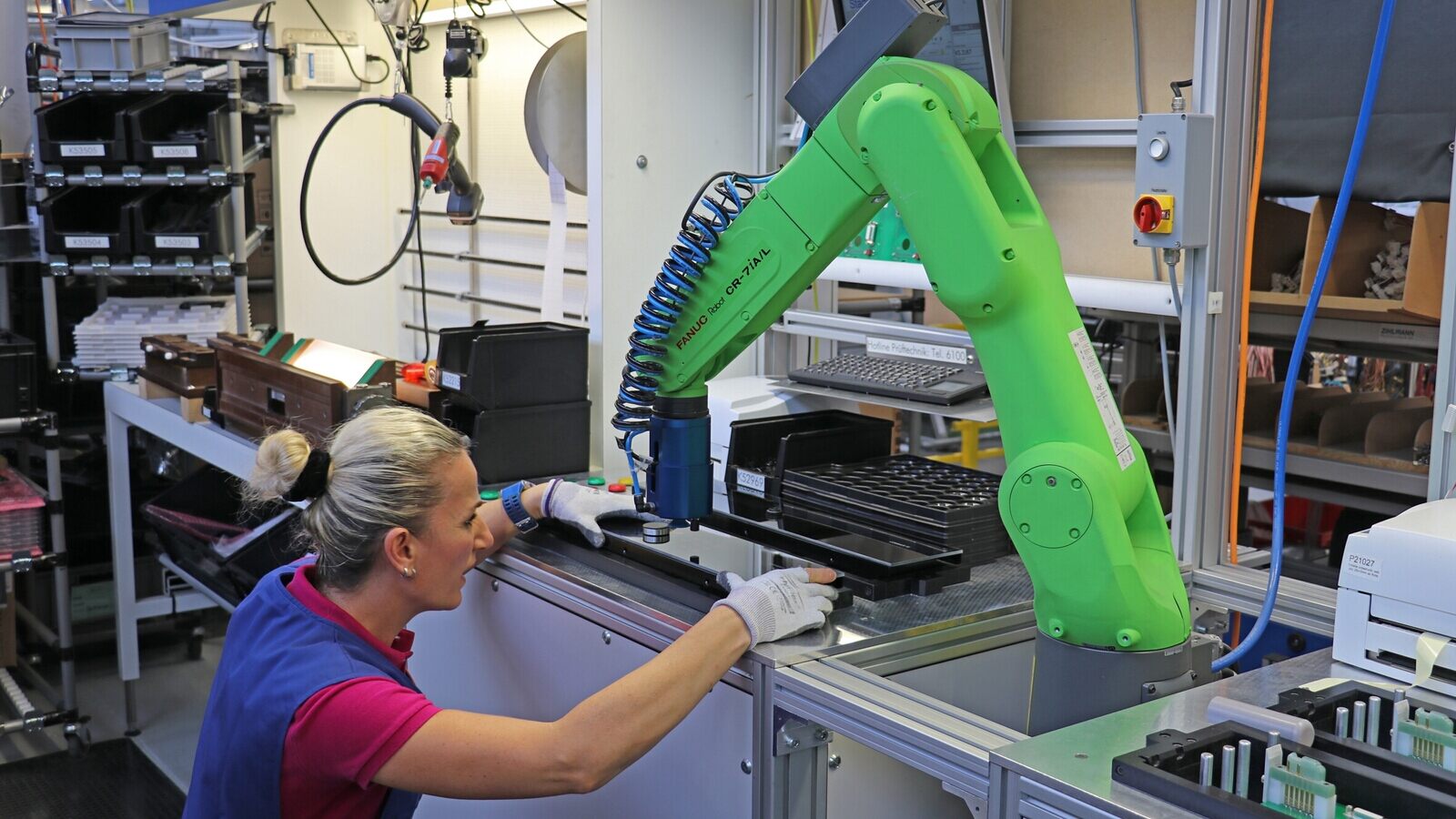

Testing

© FANUC

A FANUC CR-7iA/L collaborative robot supports assembly staff with the testing of control panels.

Handling Ceramic

© FANUC

Handling of ceramic tableware by FANUC robots

Hospital Disinfection

© OMRON

UV Disinfection Robot moves around in a hospital

Assembly and Testing

© Staubli

Assembly and test of smartphones with a SCARA and a 6 axis robot from Stäubli.

Assembly

© Staubli

Assembly application of E-mountainbikes Cube with a TX2-140 robot from Stäubli.

Monitoring

© Staubli

Monitoring of the production with a Stäubli TS2-100 robot.

Programming

© Staubli

Programming of a Stäubli TS2-100 SCARA robot.

Internal Logistics

© Mobile Industrial Robots A/S

Autonomous mobile robots transport pallets from the depot to the warehouse, manned hightrucks take over.

Hygiene Logistics

© Mobile Industrial Robots A/S

KEN Hygiene has developed a fully automated sterile center using autonomous mobile robot that works as the logistical link.

Warehouse Logistics

© Mobile Industrial Robots A/S

Automous mobile robot transports finished products from assembly lines to the warehouse - optimization of internal logistics

Cobot Palletizing

© YASKAWA

Safe palletizing with Yaskawa collaborative robot

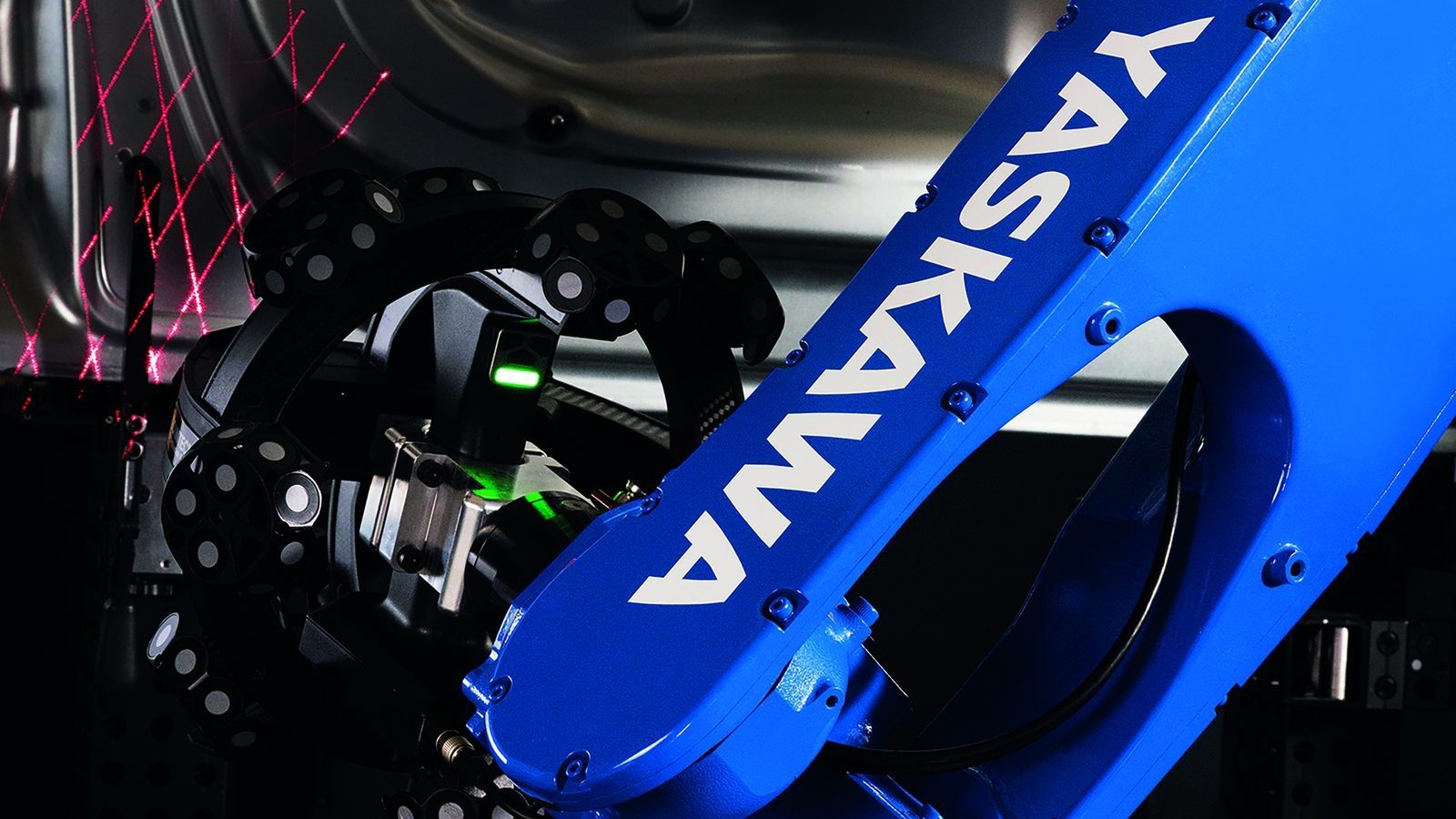

Deburring and Chamfering

© YASKAWA

Robot deburring cell with the Yaskawa handling robot deburring and chamfering all types of gearing components.

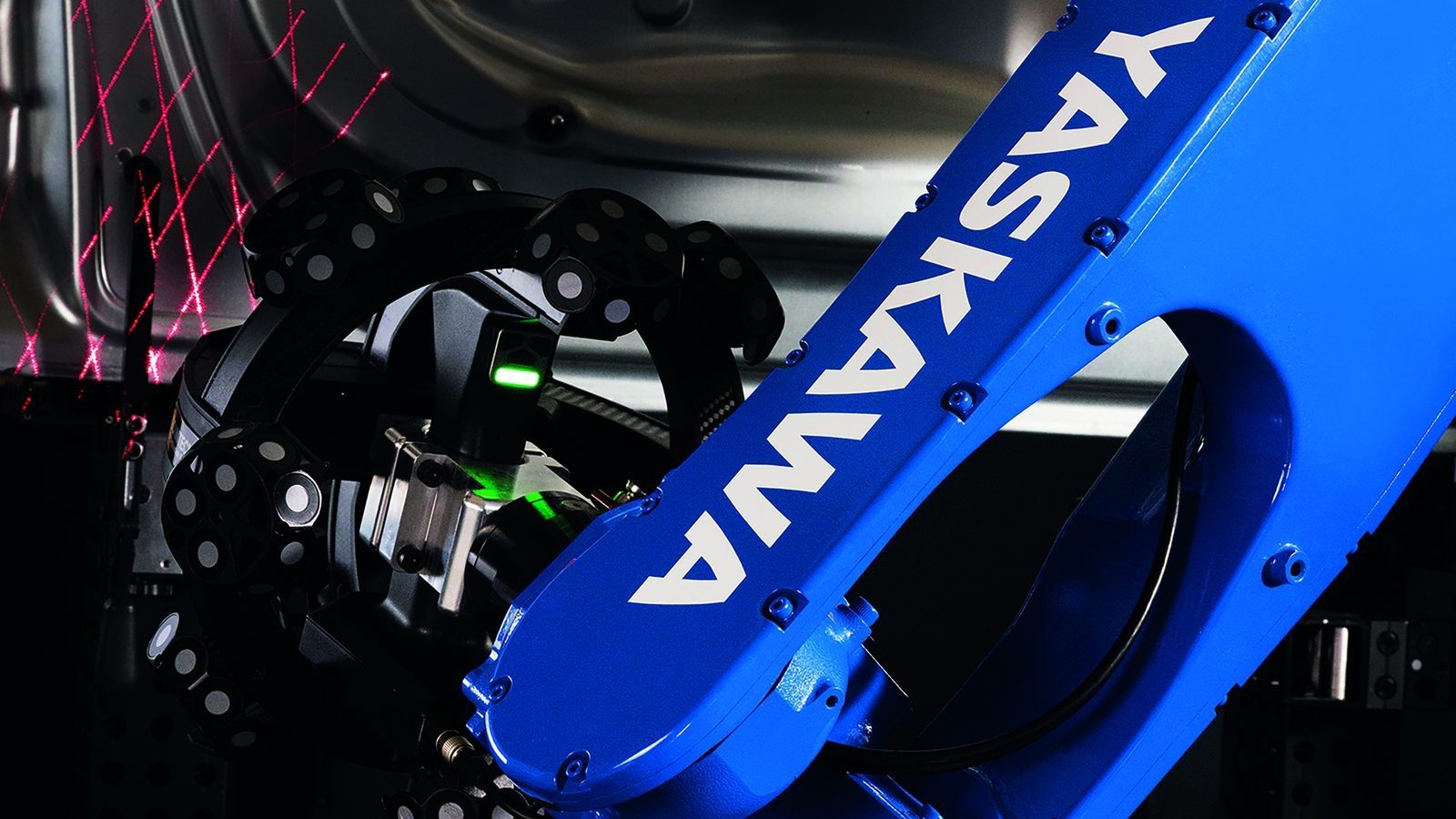

Car Measurement

© YASKAWA

Turn-key complete cell MANTIS with Yaskawa handling robot enables measurement of a car side door in a matter of minutes.

Collaborative Robot Programming

© Photoneo

Programming and working with a collaborative robot.

Robot Vision

© Photoneo

Adjustments on an industrial robot and the vision system

Robot getting Eyes

© Photoneo

Mechanic setting up the vision system on an industrial robot.

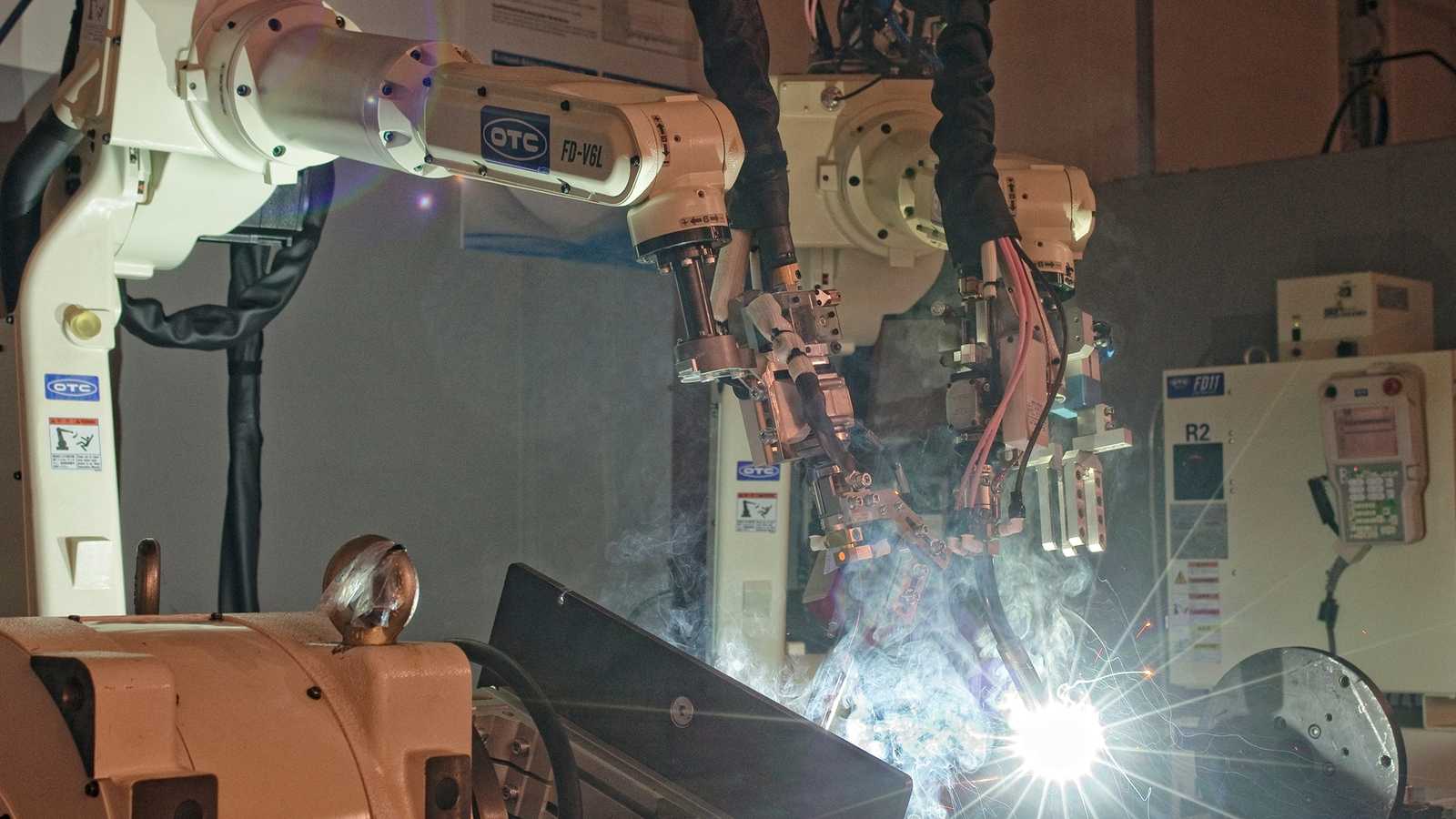

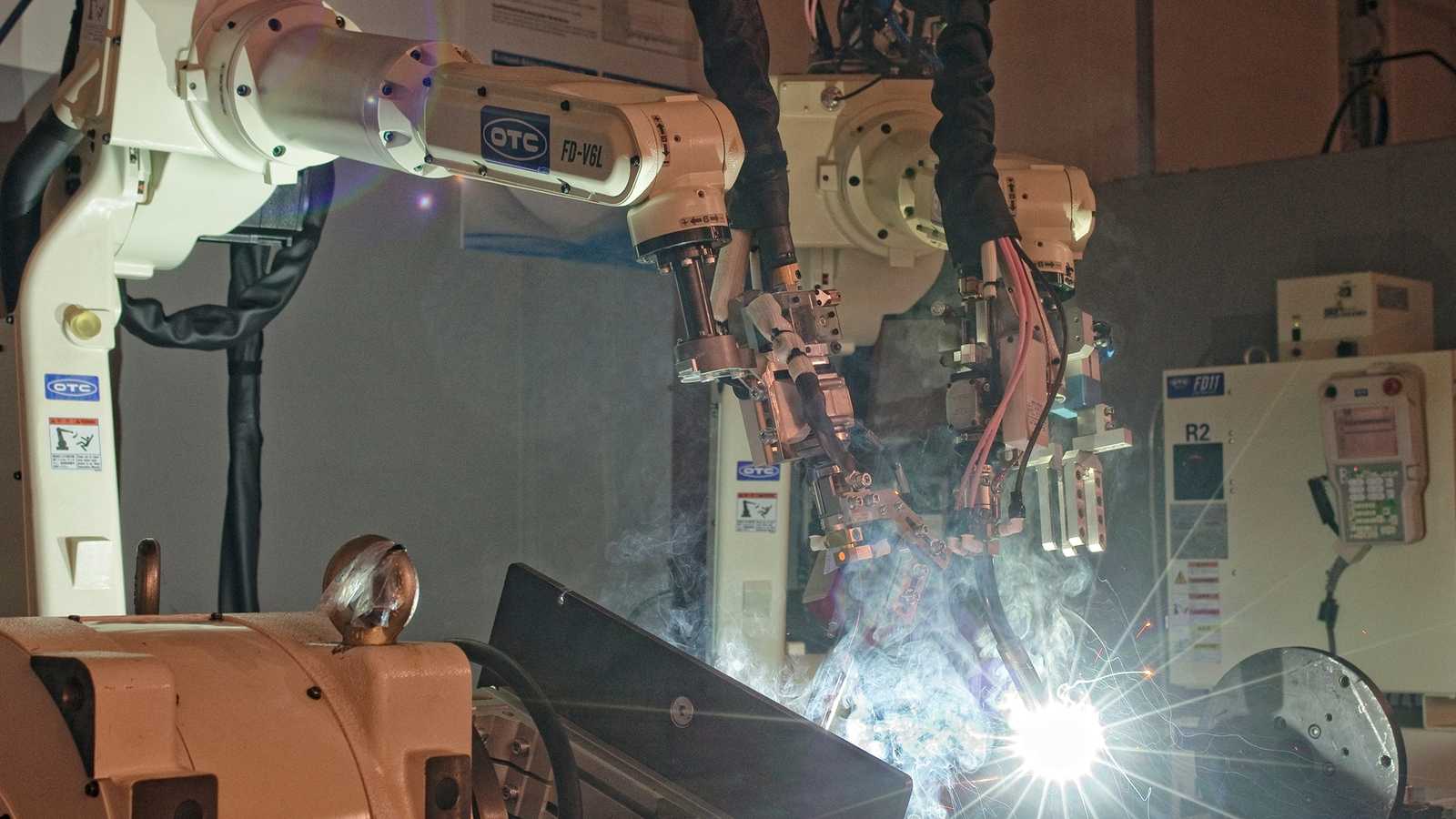

Aluminum Welding

© OTC Daihen

Robot twin system of two robots and a positioner - fully automated aluminum welding with high-speed welding process AC/MIG.

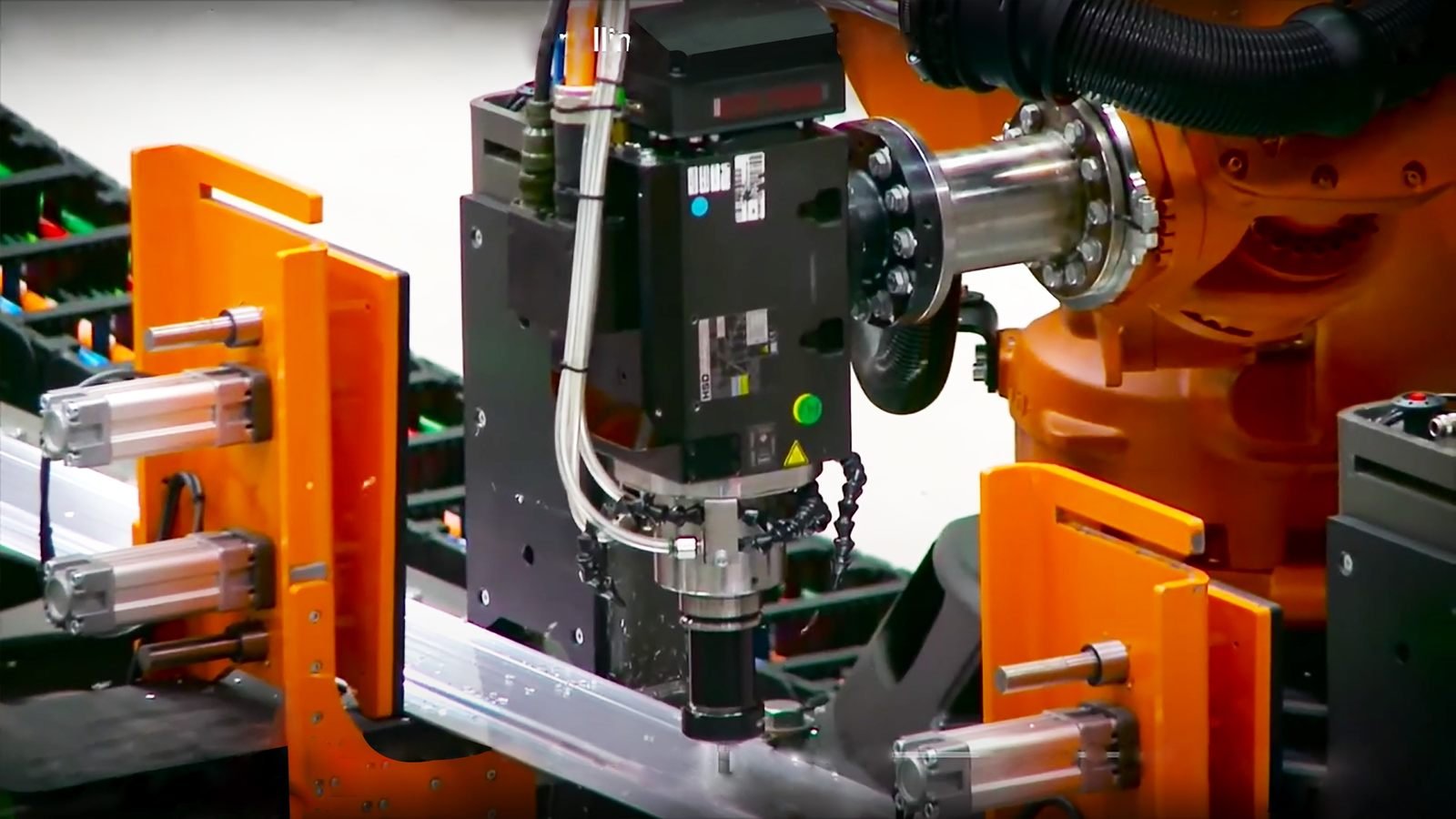

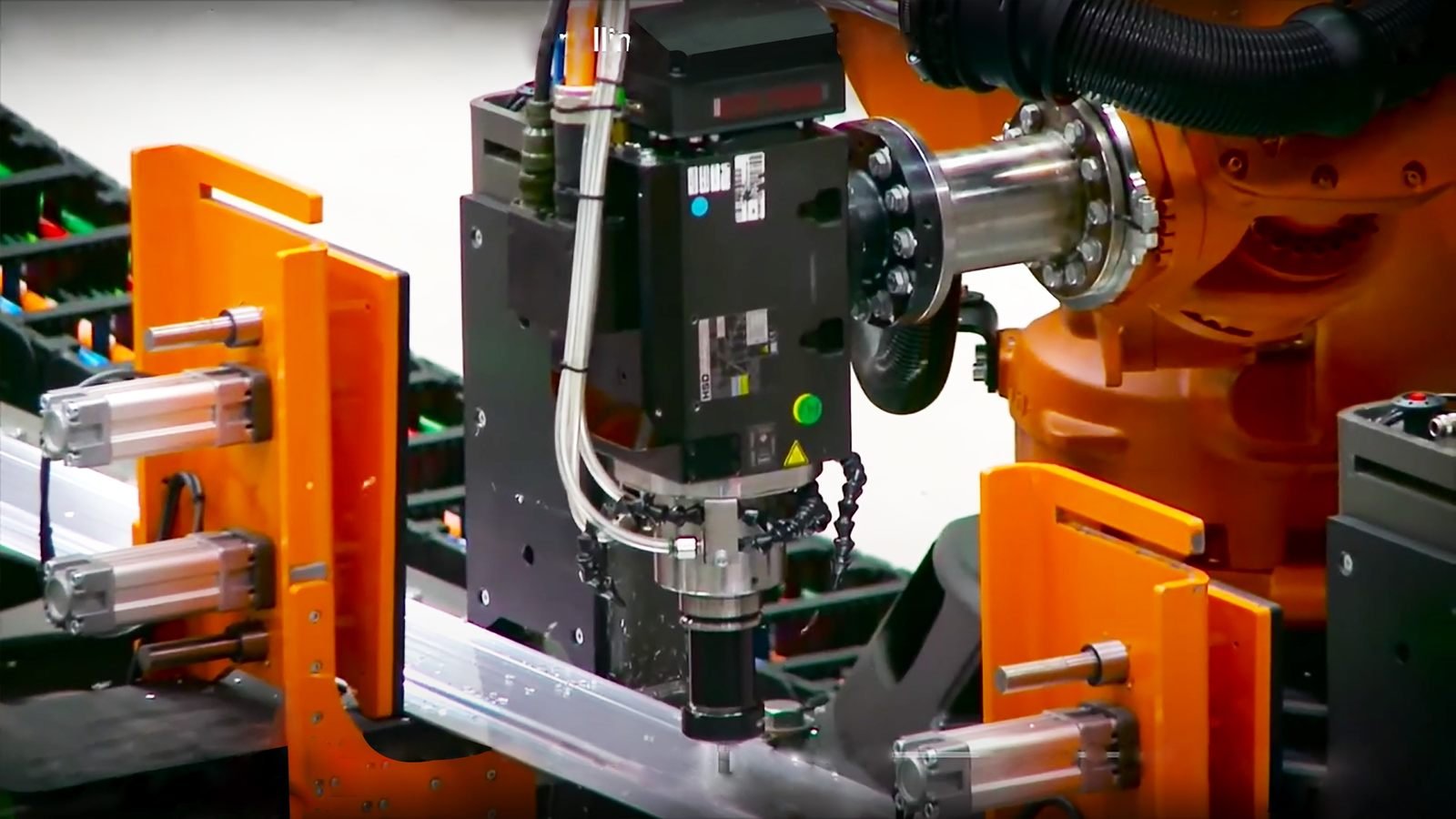

Aluminum Work

© HSD

The HSD electrospindles are used for robotic milling applications on aluminum frames.

Marble Work

© HSD

HSD electrospindles working even on rigid surfaces like marble.

Milling Application

© HSD

The HSD electrospindles are used for robotic milling applications

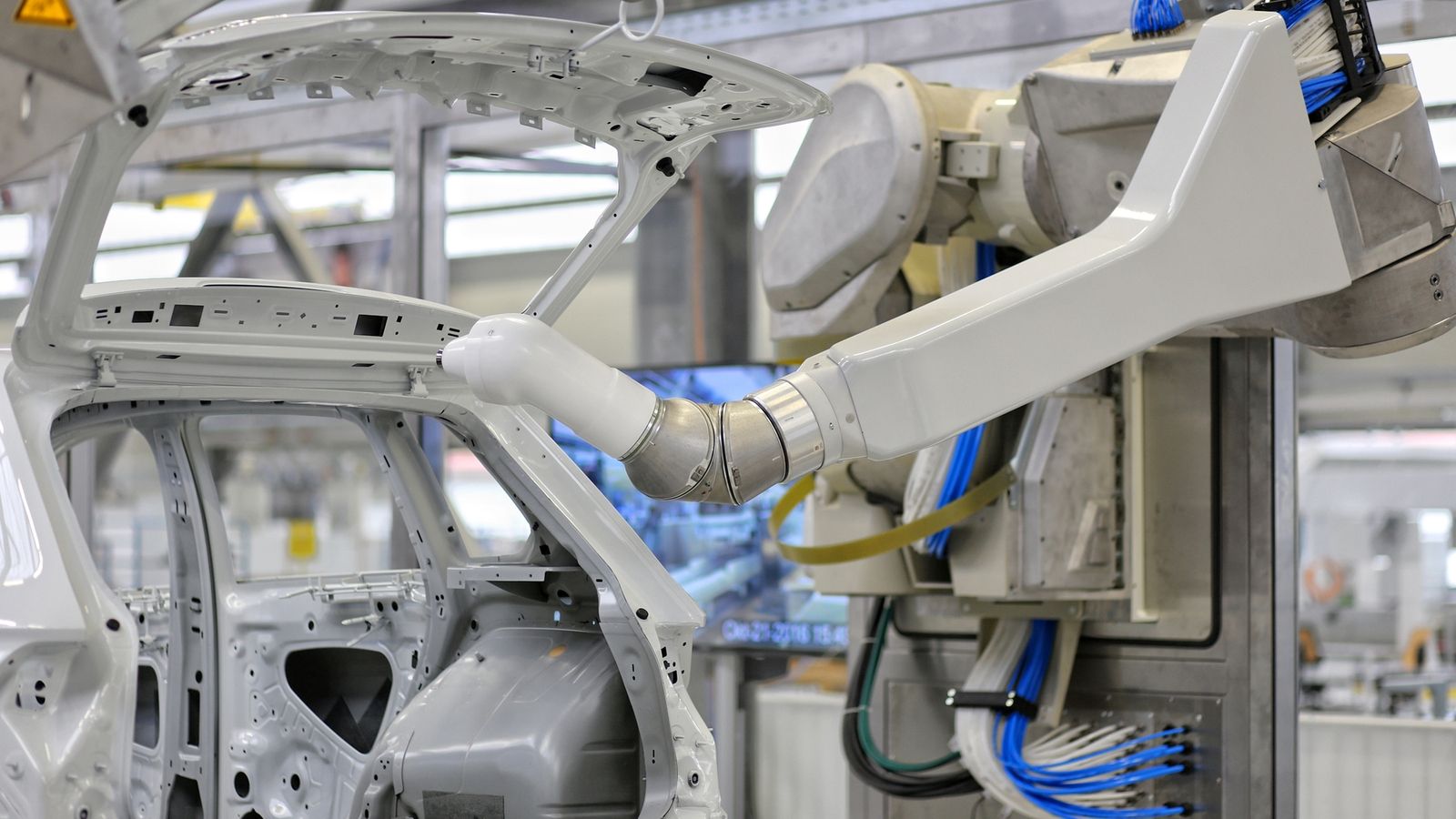

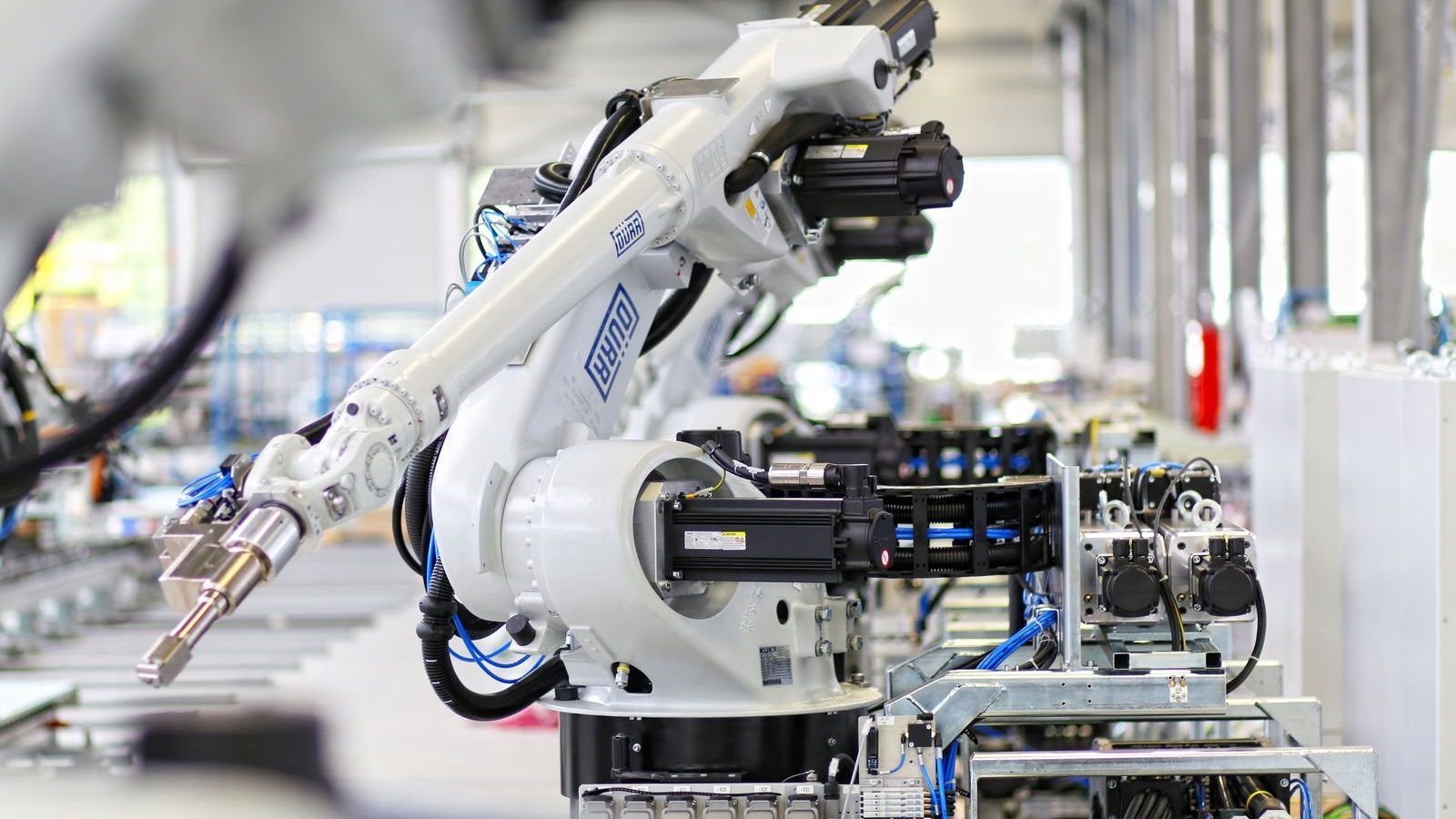

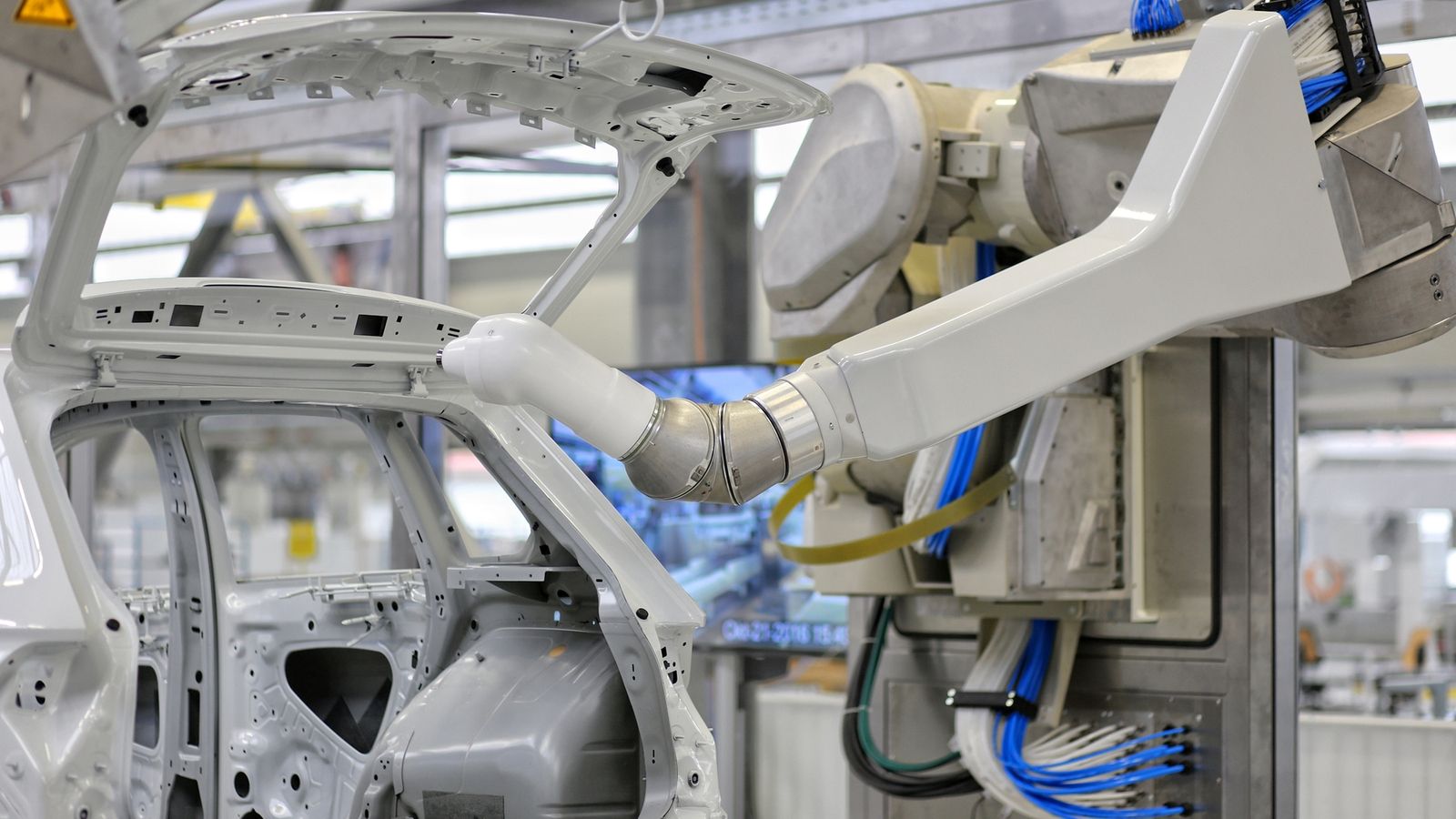

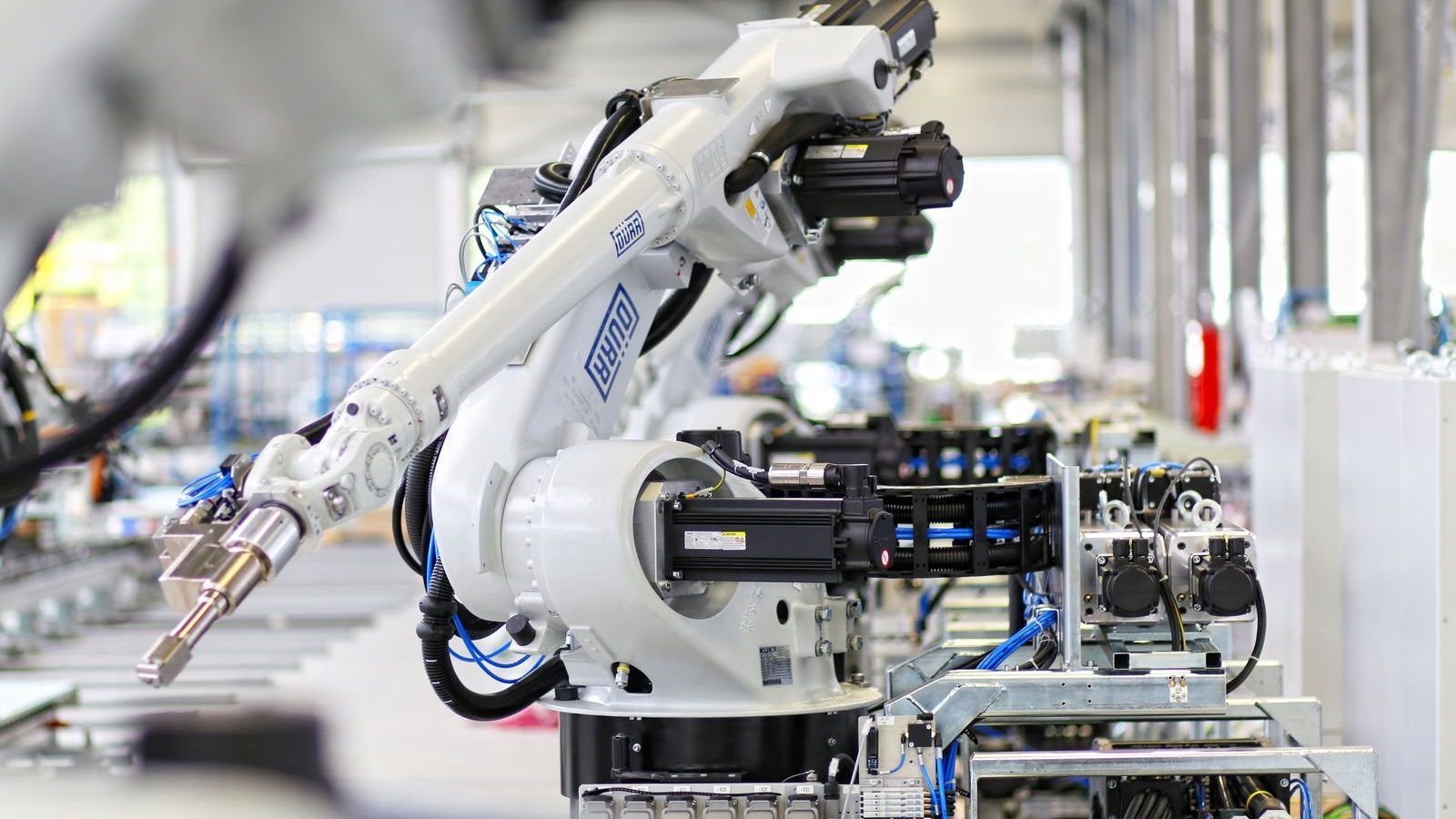

Total Freedom of Movement - 7 Axis

© Duerr

The robot with a seven axis reaches every spot in the car body. This can eliminate the need for a linear displacement rail.

Overspray-free Paint Application

© Duerr

EcoPaintJet is an innovative system for automated, highly defined paint application without any overspray.

Sealing Application

© Duerr

Robot EcoRS 30L16S with shortened arm 1 is particularly suitable for sealing applications inside car bodies.

Logistics

© OMRON

Automous mobile robots safely and efficiently transport different payloads in manufacturing and warehouse logistics operations.

Cobot Application

© OMRON

Collaborative robots can work side-by-side with humans in many applications, e.g. closing CNC machine.

Scara Production Line

© OMRON

Seamless integration of robots and machine control allows flexible manufacturing of fixed industrial robots

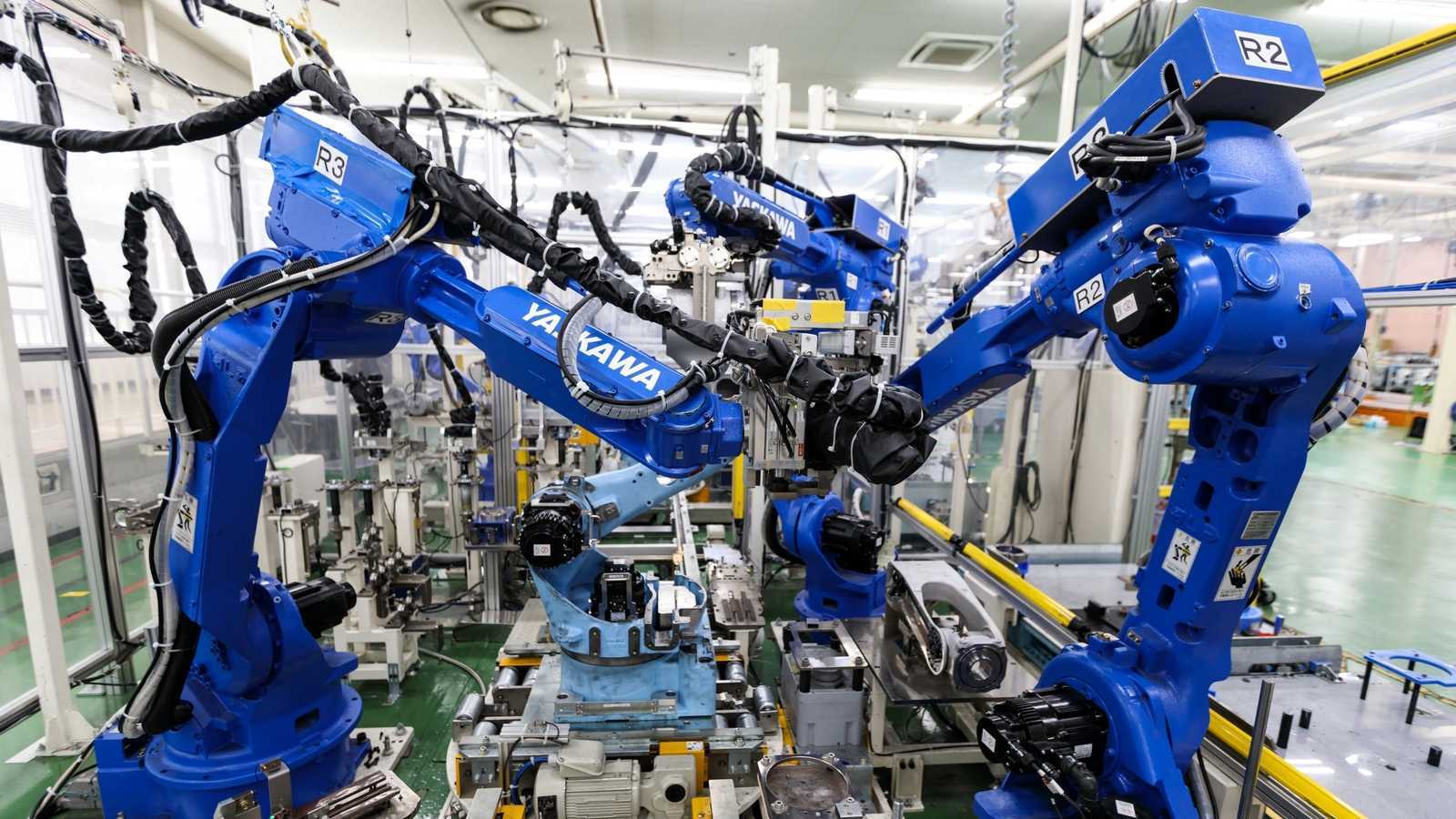

Assembly

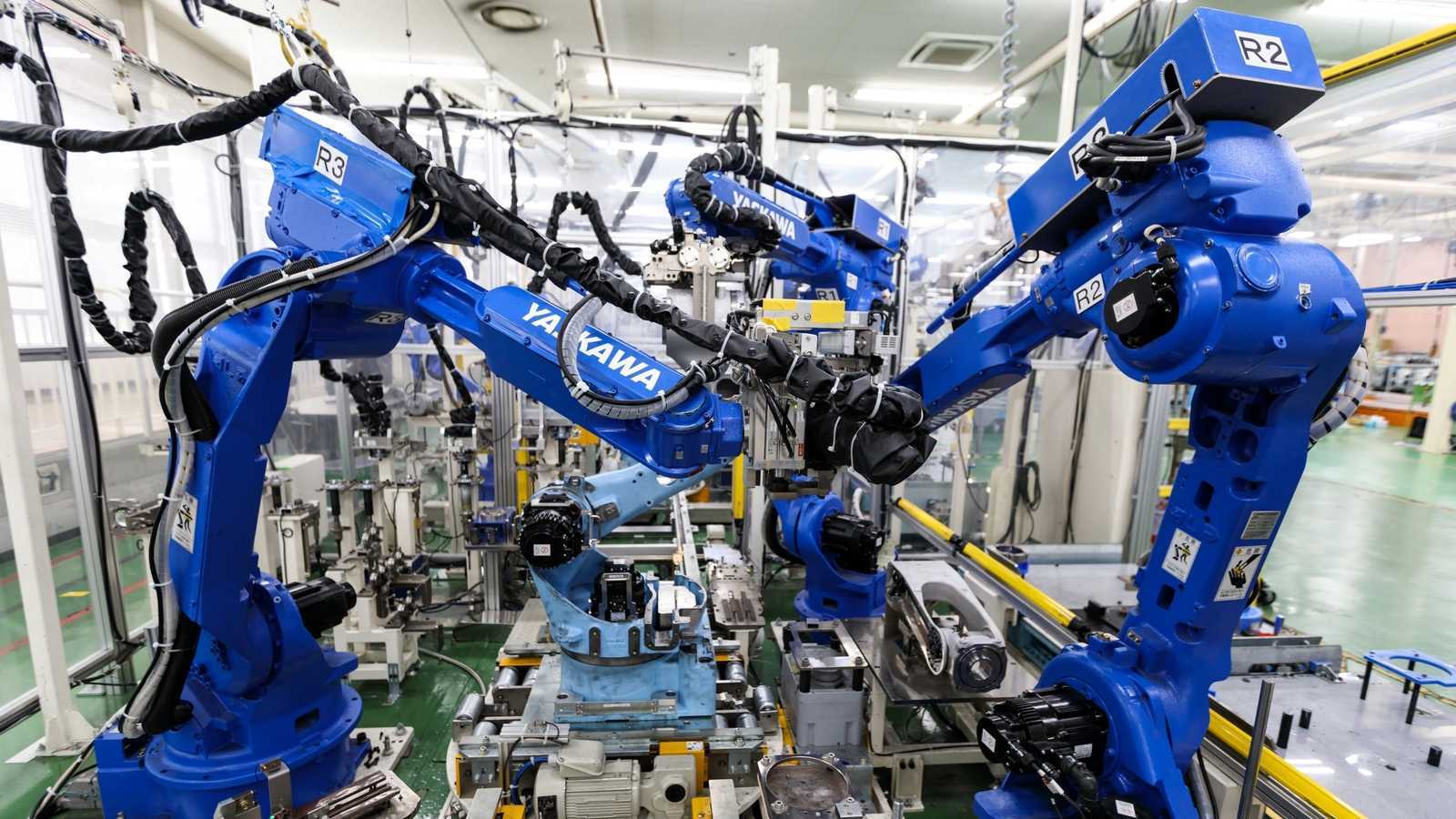

© YASKAWA

YASKAWA robots assemble robots for automation of the factory

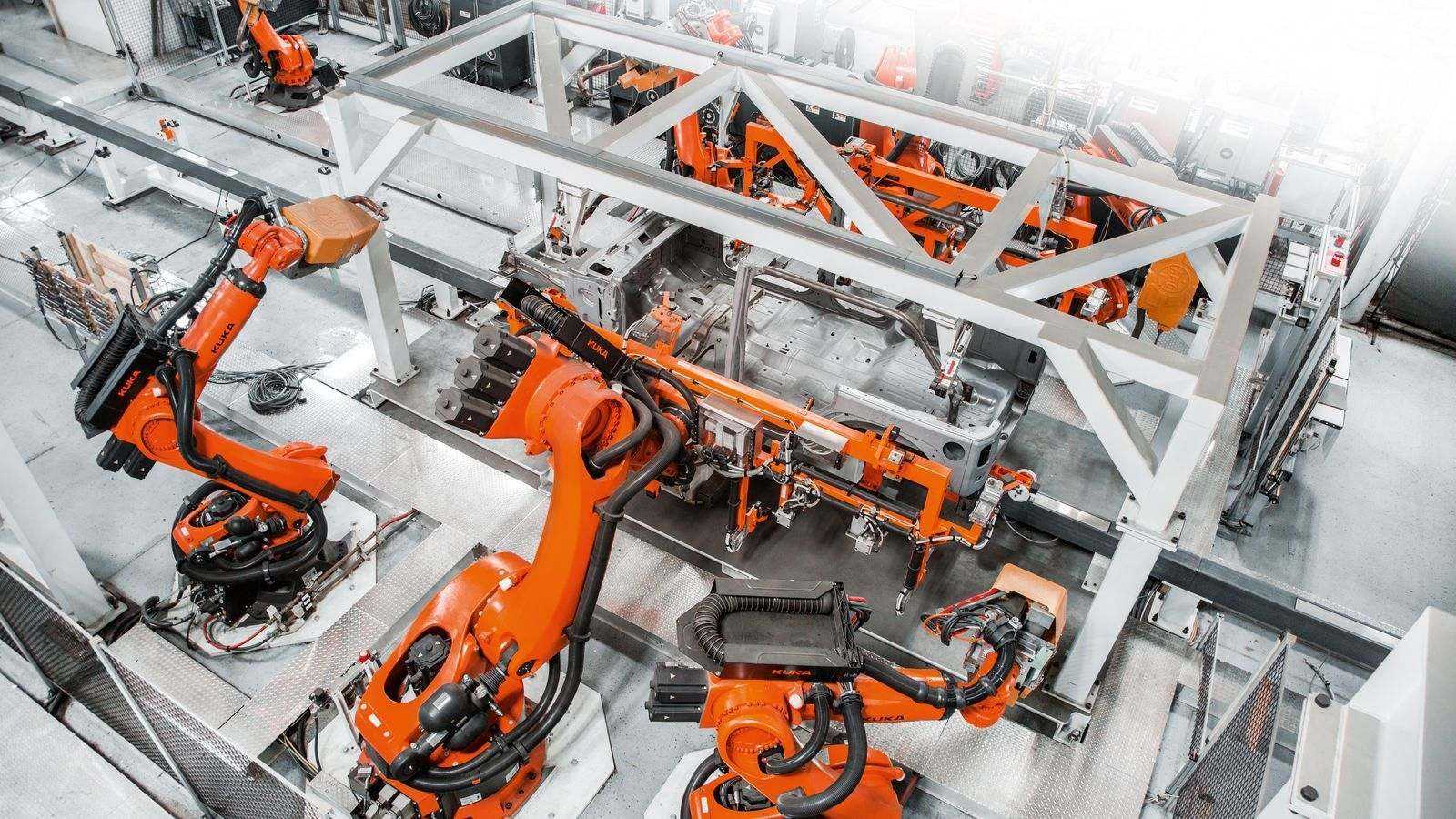

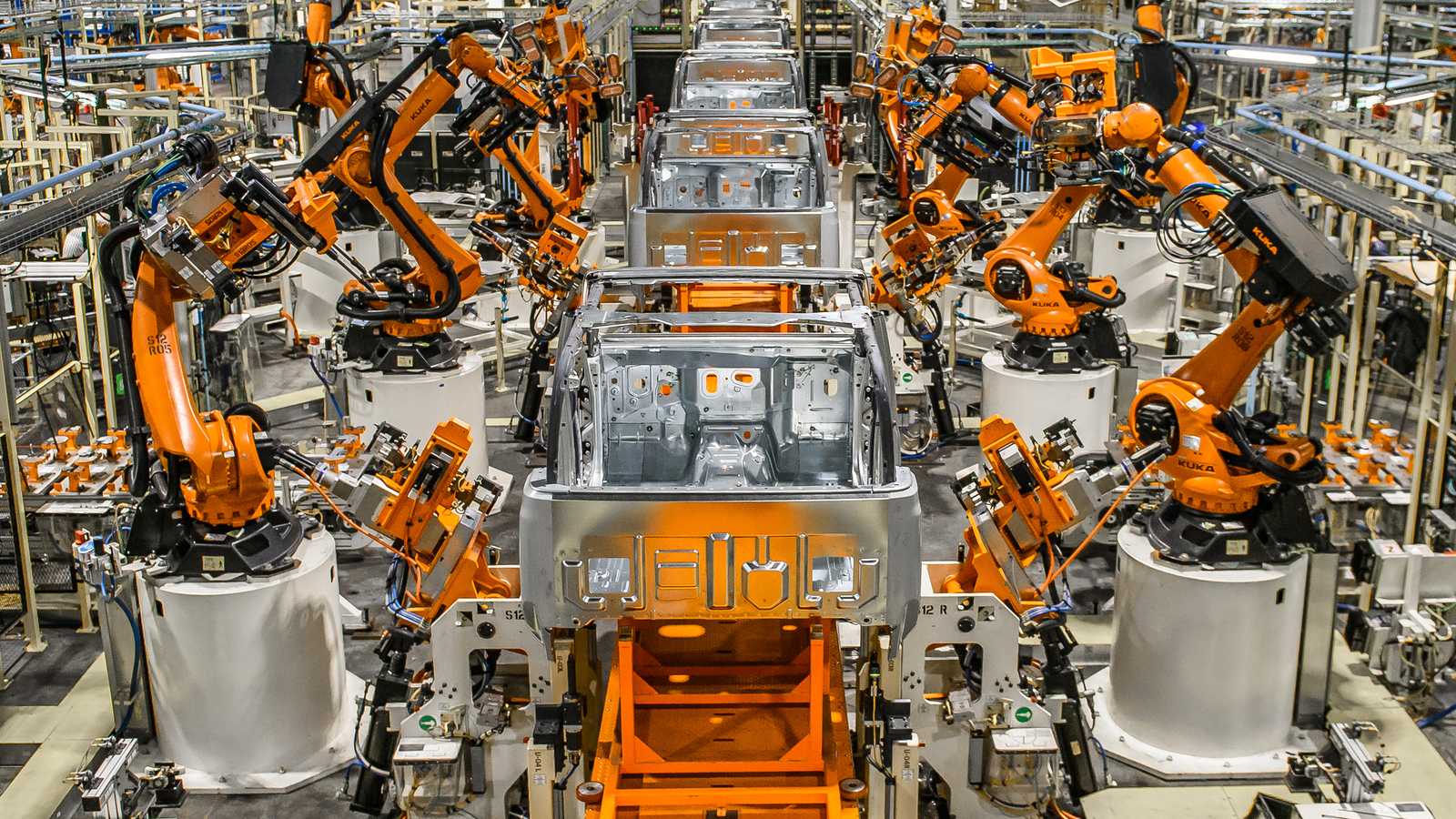

Digital Supply Chain

© KUKA

The body-in-white plant KUKA Toledo Production Operations set new milestone in terms of digital supply chain and Industrie 4.0.

Soft Hand Gripper

© qbrobotics srl

SoftHand grasping a trolley handle with ability changing the angle of the wrist

Food Packaging

© OnRobot

Heavy and monotone tasks can be taken from the employees with a collaborative robot and special gripper.

Laboratory

© OnRobot

The OnRobot RG6 gripper is changing tests quickly by simply clipping and unclipping at L'Oréal.

Primary Packaging

© OnRobot

Two sets of dual gripper stack plastic molded containers, making them ready for packaging.

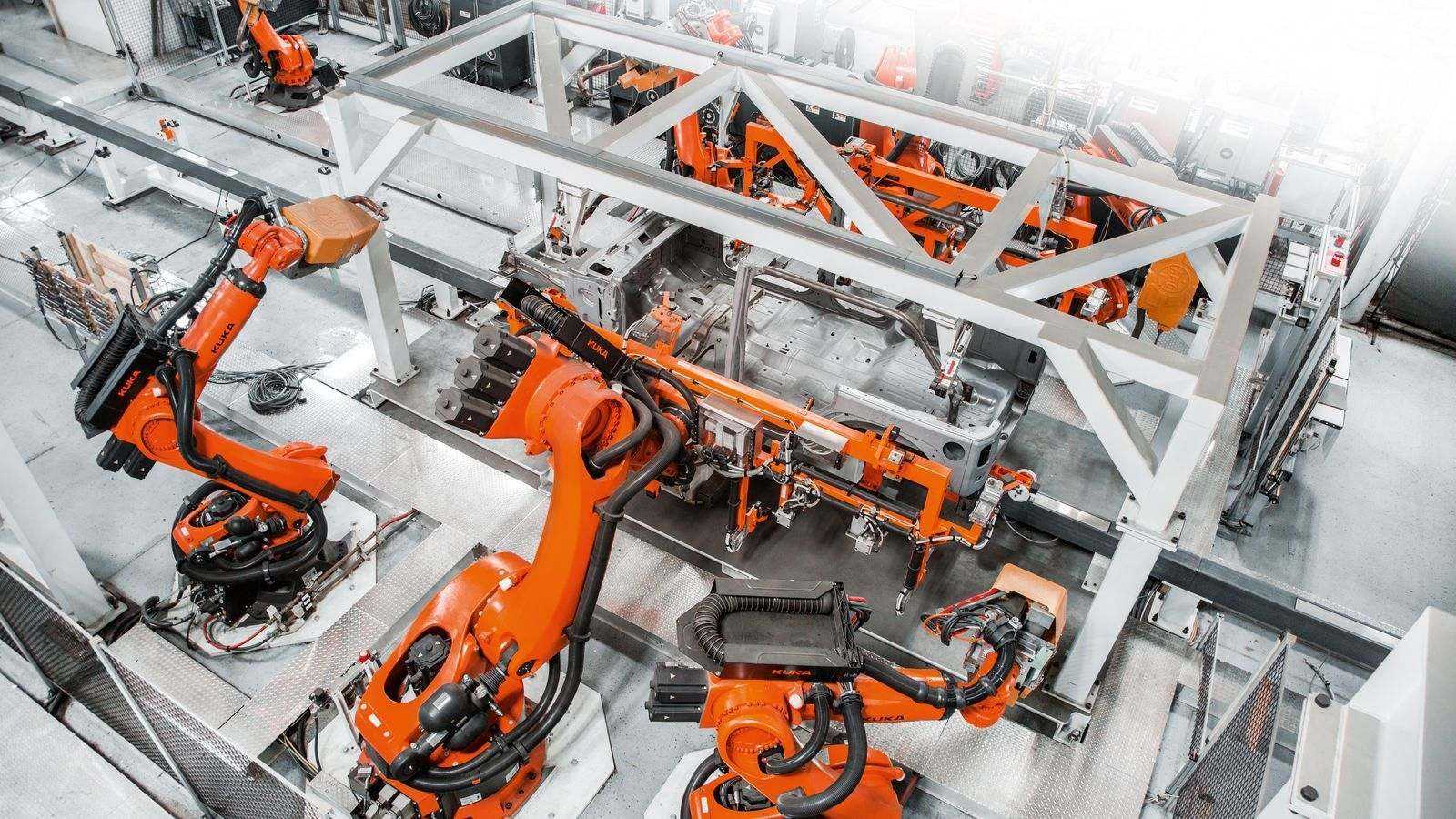

Smart Production

© KUKA

Smart Production in a factory

Cobot mounted on AMR

© NEURA Robotics GmbH

LARA (Lightweight Agile robotic assistant) mounted on MAV (Multi-Sensing Autonomous vehicle) palletizing products

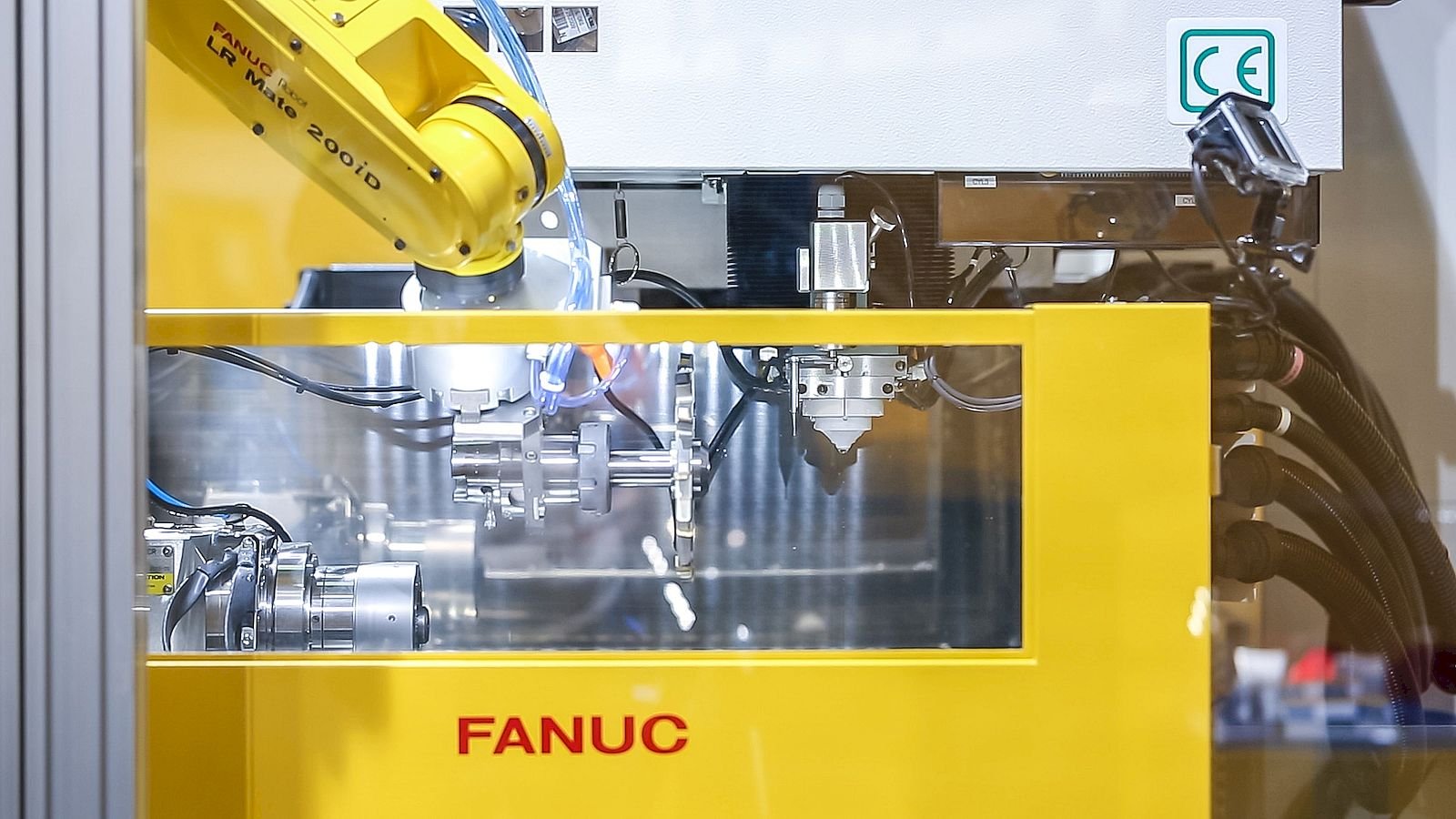

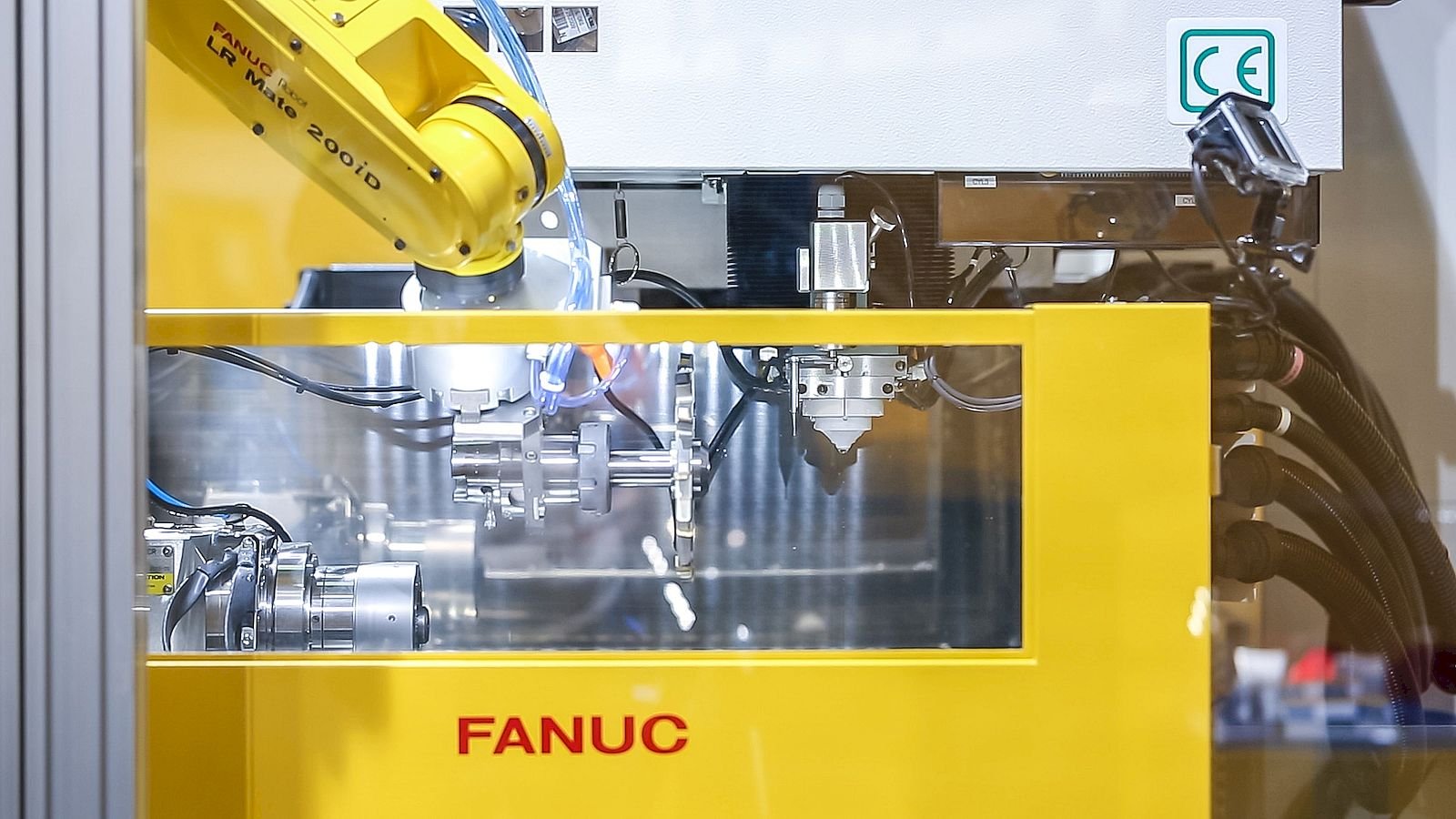

Wire Cutting

© FANUC

A FANUC Robot LR Mate 200iD is loading a WireCut EDM machine

Collaborative Robot

© ABB

YUMI is ABB's collaborative robot on the market

Electronics industry

© ABB

Robots at assembly line in the electronics industry

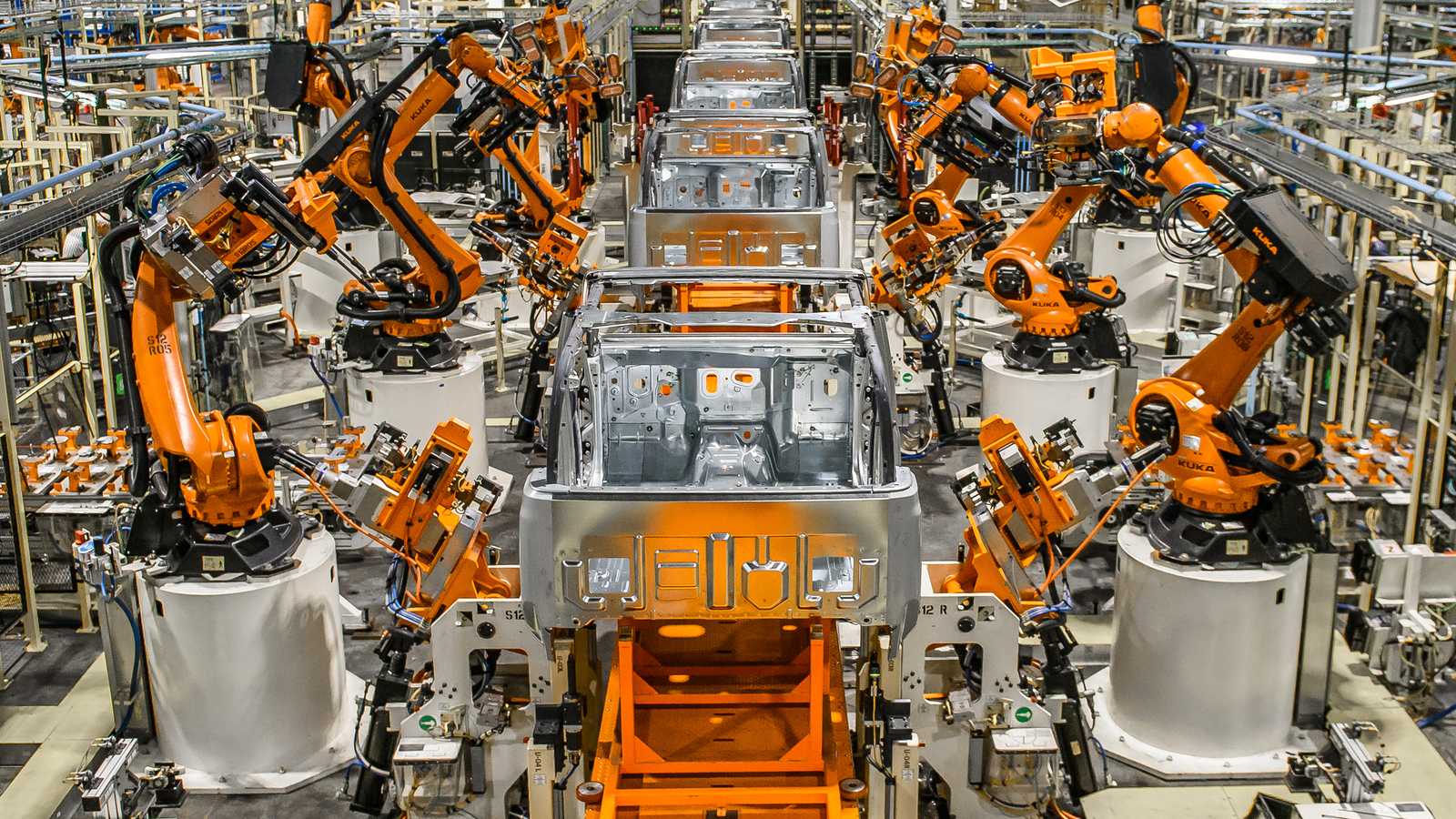

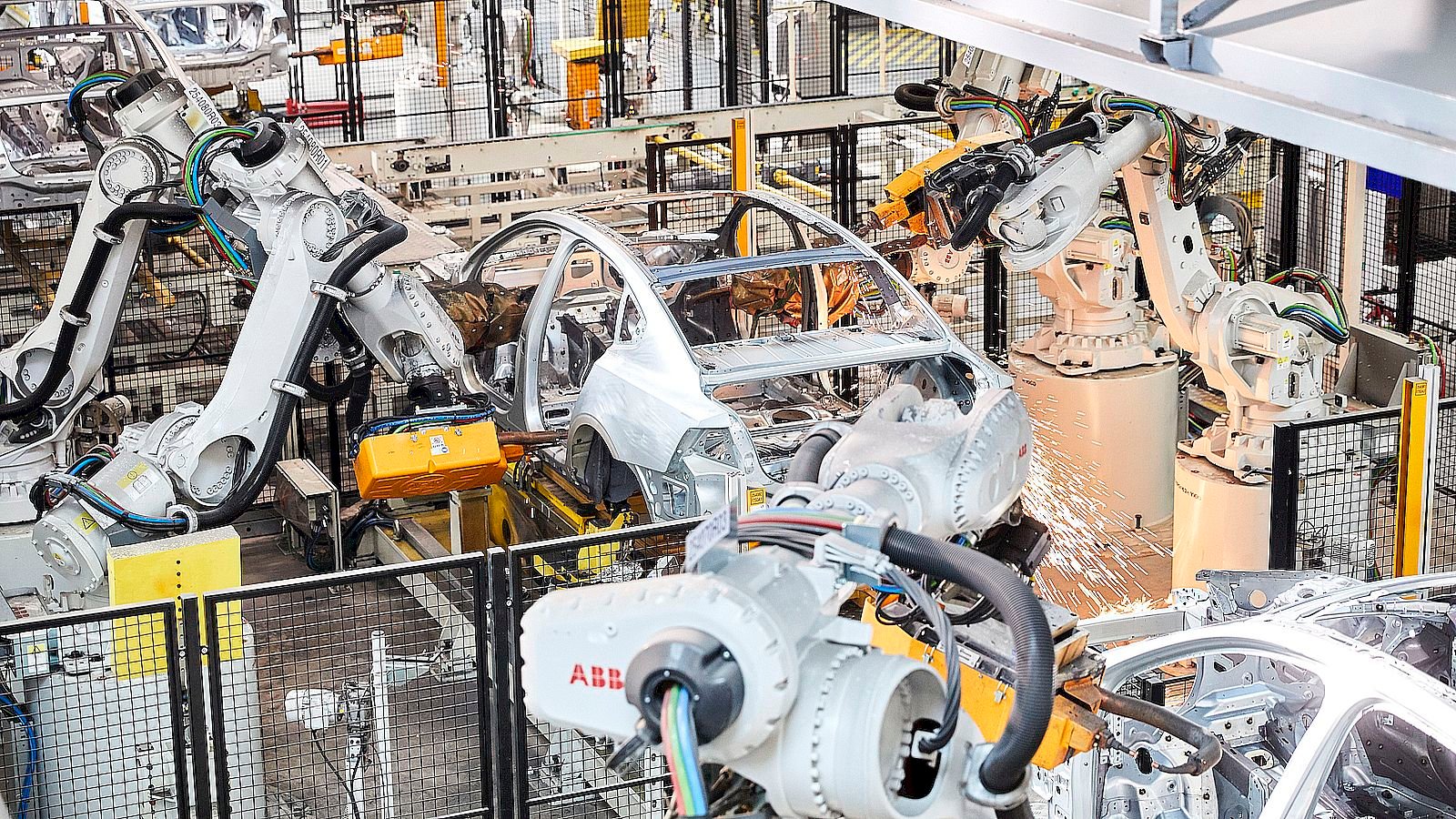

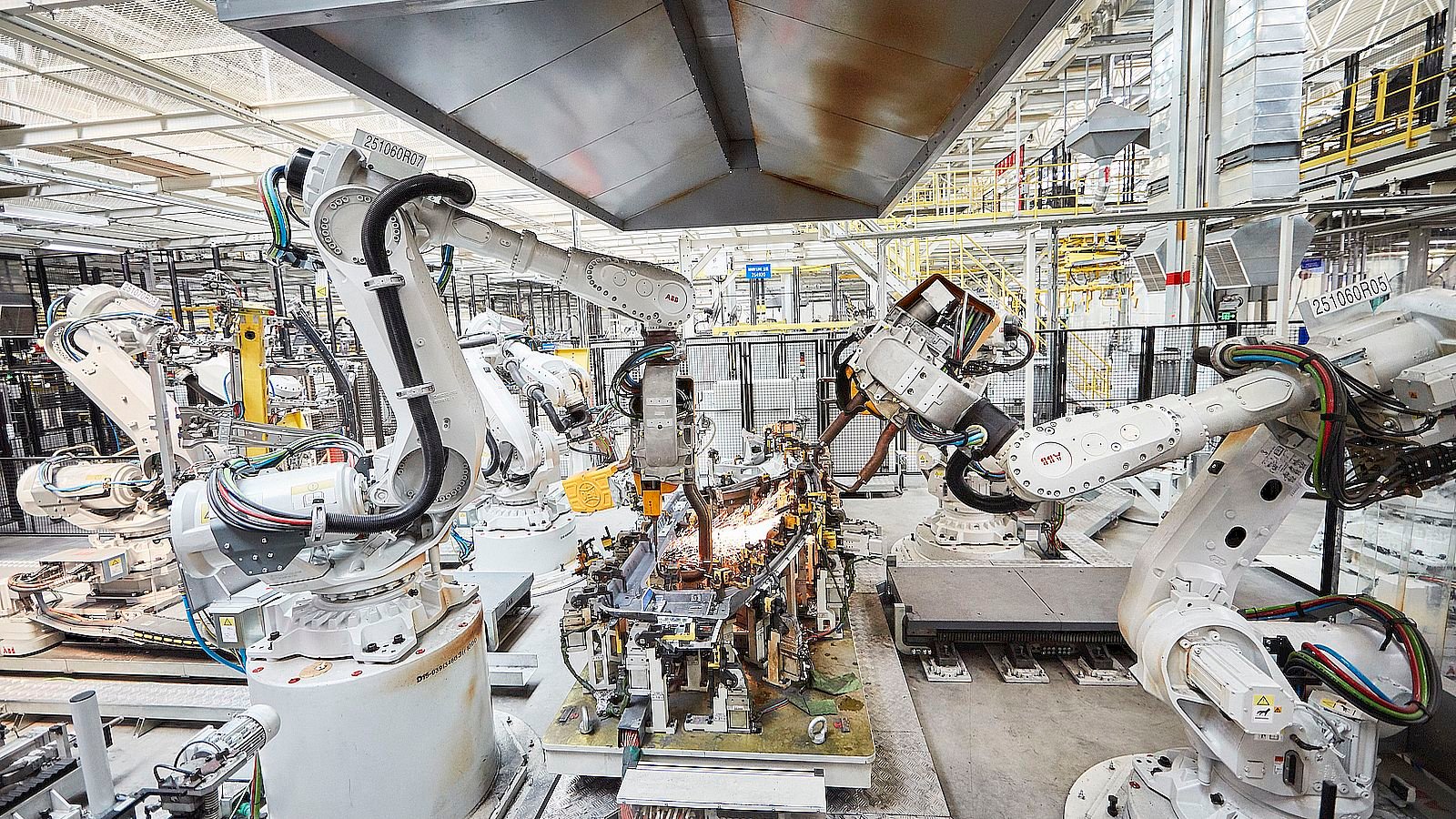

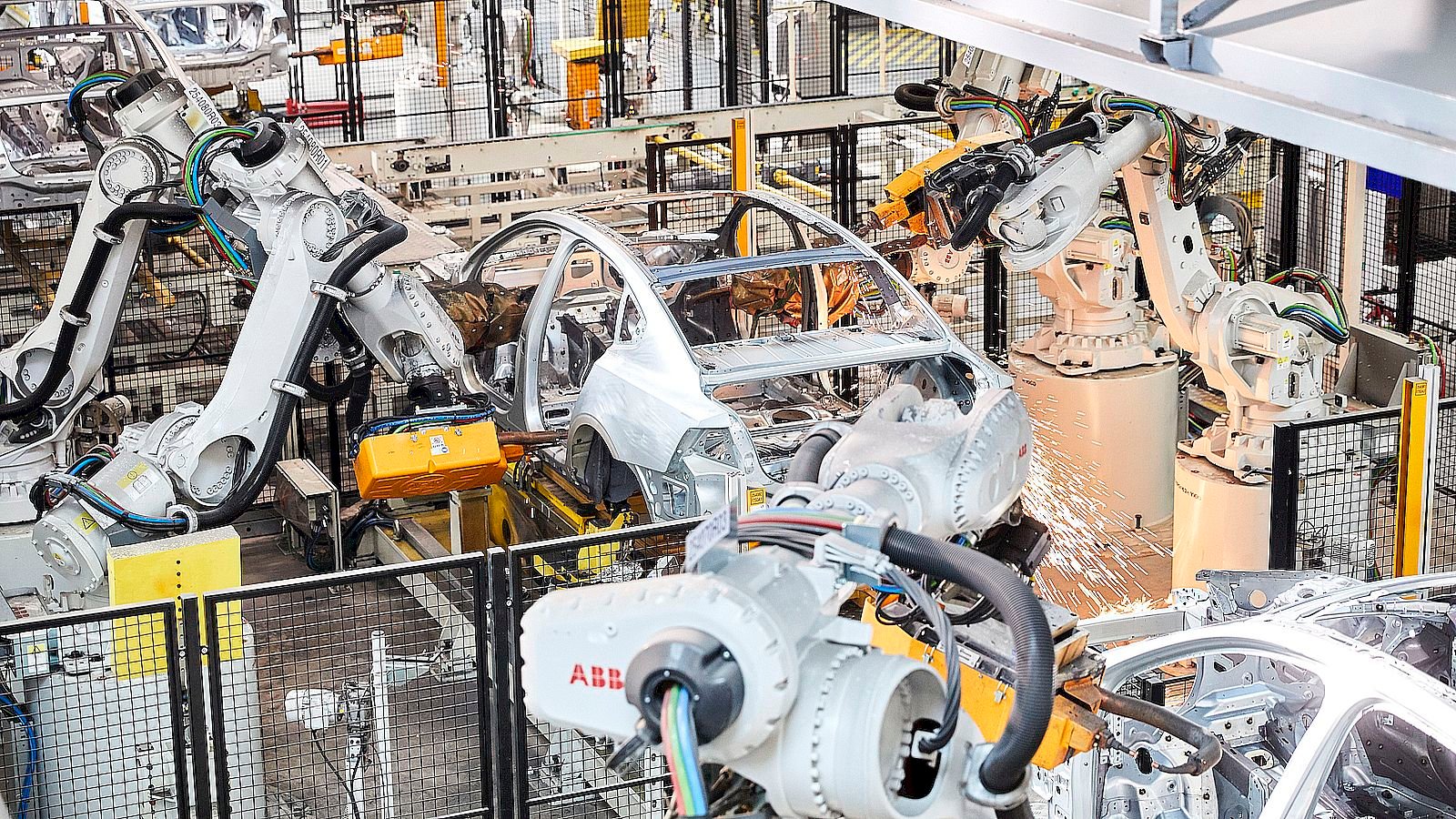

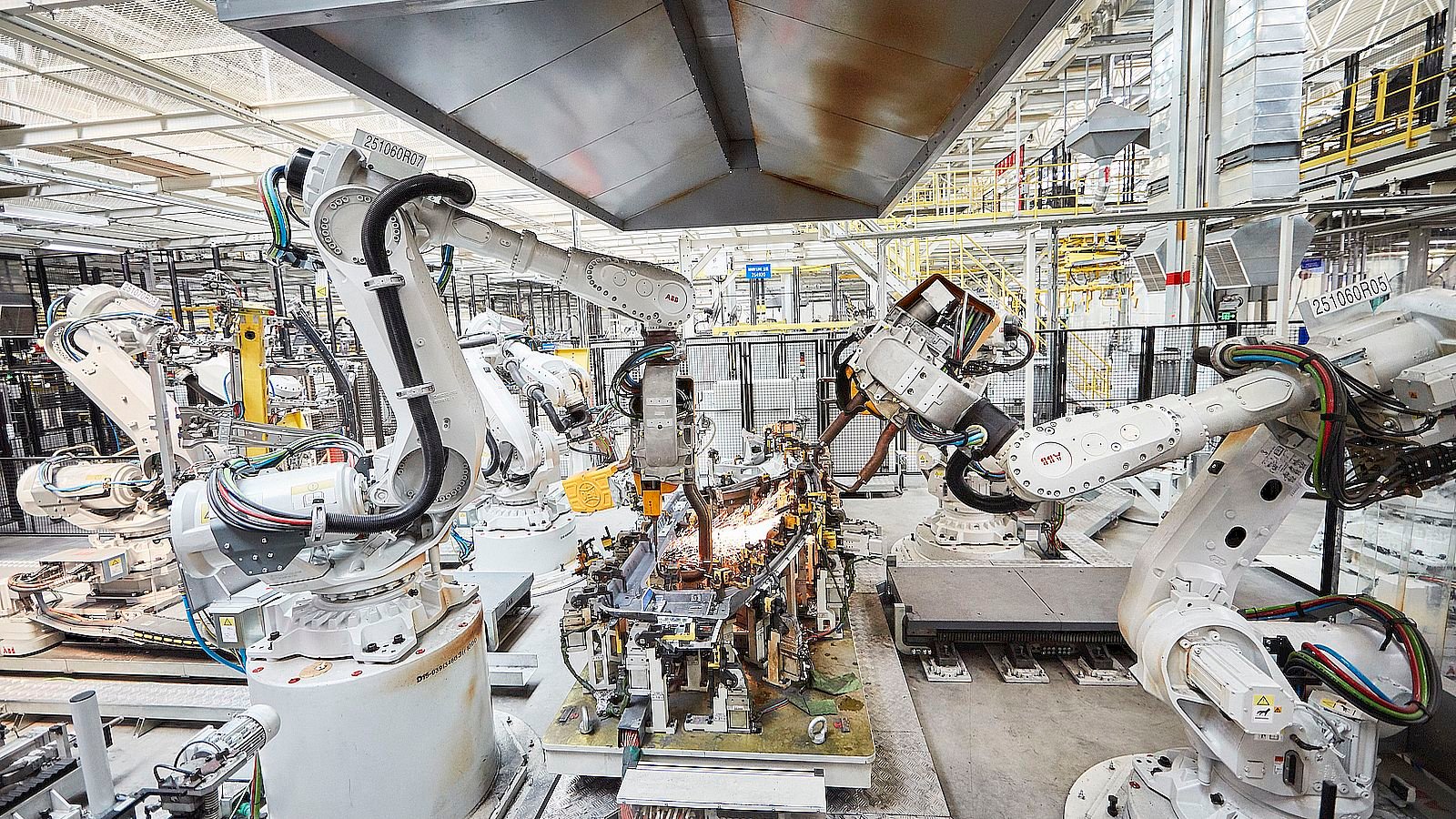

Automotive welding

© ABB

Robots welding car chassis in the automotive industry

Automotive welding

© ABB

Robots welding parts in the automotive industry

UR5 - A highly flexible robot arm

© Universal Robots

UR5 robots (payload 5kg) carry out machine tending on CNC machines

UR3 - ultra-flexible table-top robot

© Universal Robots

UR3 robots (payload 3kg) to screw drive the caps on consumer goods at MARKA.

Cheese Handling

© Staubli

Cutting and Handling of Cheese

Automotive

© Staubli

Automotives - Automation

Programming

© YASKAWA

Using the teach pendant for programming, or touch up of previously made offline programs.

Printing

© CoolGraphics/Yaskawa

MOTOMAN dual arm robot in a co‐worker robot cell separates, airs and moves stacks of printed paper sheets.

Labrobot

© YASKAWA

The MOTOMAN dual arm robot in a biomedical cell where it performs all the necessary tasks in a laboratory environment.

Cleanfix

© BlueBotics 2017

Cleanfix - RA 660 - ANT driven cleaning a floor

ANT driven AGV

© BlueBotics 2017

AGV Scandinavia - ANT driven forklift