Definition

The IFR’s use of the term “industrial robot” is based on the definition of the International Organization for Standardization: an “automatically controlled, reprogrammable multipurpose manipulator, programmable in three or more axes, which can be either fixed in place or fixed to a mobile platform for use in automation applications in an industrial environment". (ISO 8373:2021)

The terms used in the definition mean:

- Reprogrammable: designed so that the programmed motions or auxiliary functions can be changed without physical alteration (alteration of the mechanical system);

- Multipurpose: capable of being adapted to a different application with physical alteration;

- Manipulator: mechanism consisting of an arrangement of segments, jointed or sliding relative to one another;

- Axis: direction used to specify the robot motion in a linear or rotary mode.

Industrial robots can be classified according to mechanical structure:

- Cartesian robot (rectangular robot, gantry robot): manipulator which has three prismatic joints, whose axes form a Cartesian coordinate system

- SCARA robot: manipulator which has two parallel rotary joints to provide compliance in a selected plane

- Articulated robot: manipulator which has three or more rotary joints

- Parallel/Delta robot: manipulator whose arms have links which form a closed loop structure

- Cylindrical robot: manipulator which has at least one rotary joint and at least one prismatic joint, whose axes form a cylindrical coordinate system

- Polar robot (spherical robot): manipulator which has two rotary joints and one prismatic joint, whose axes form a polar coordinate system

Find out more about the different robot types in the file below.

Statistics

The IFR Statistical Department compiles statistical data on annual installations of multipurpose industrial robots for around 40 countries, broken down into areas of application, customer industries, types of robots and other technical and economic aspects. The results are available in the study World Robotics - Industrial Robots.

Case Studies and Use Cases

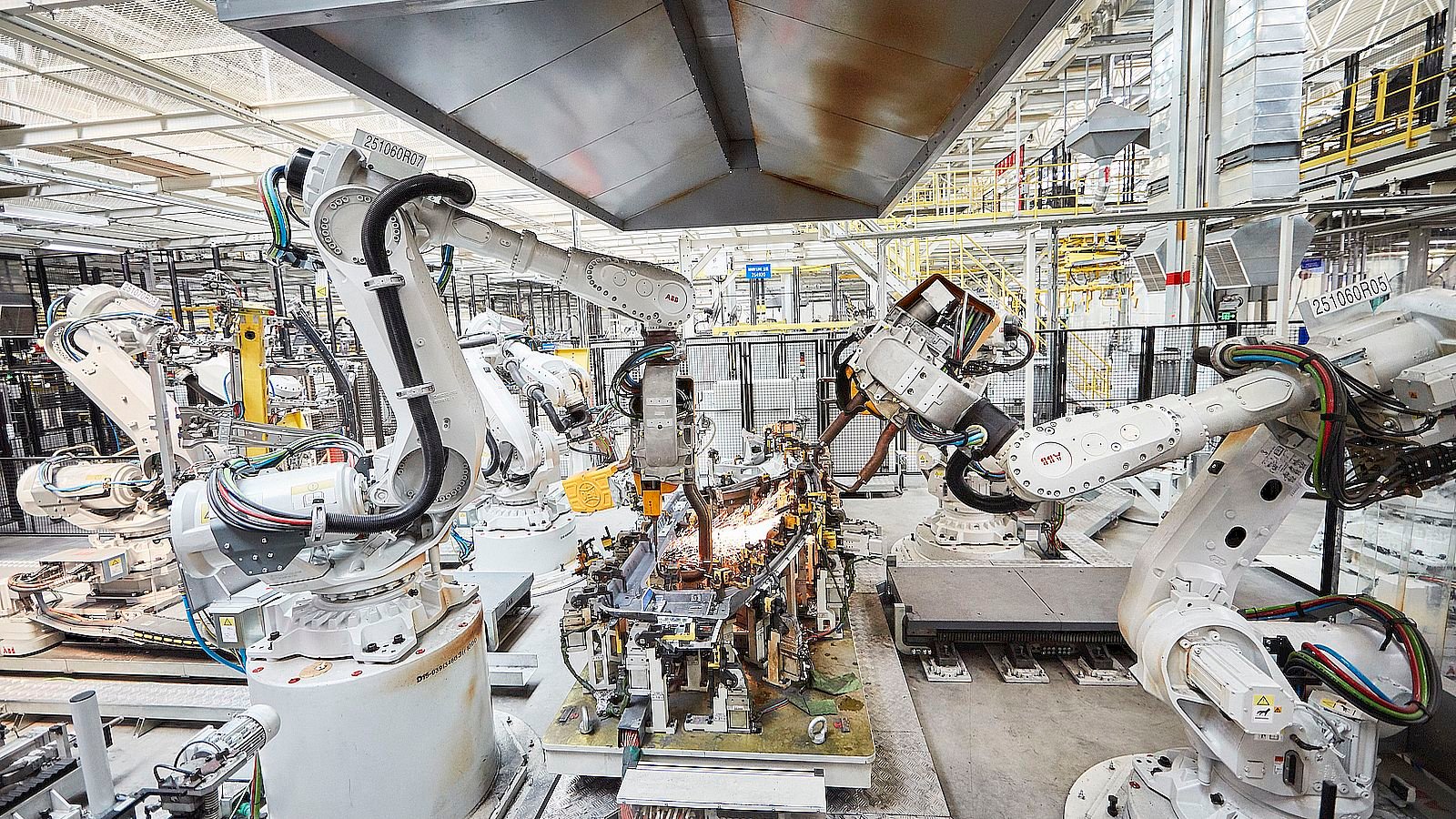

Significantly improved robot system performances and an increased ease of use open up new automation solutions, many of which are outside the “classic” applications of industrial robots. Furthermore, robot manufacturers and system integrators are increasingly supplying flexible work cells with standard configurations, which can be rapidly integrated into existing production systems for standard applications.

This implies that even small-volume productions can effectively be automated in areas such as parts welding and cutting, flexible assembly and packaging and palletizing. Robot investments are becoming more and more profitable and hence become increasingly widespread within industry.

Case studies on industrial robots can be found here.

Standardization

The International Organization for Standardization (ISO) is the worldwide federation of national standards organizations. Standards concerning robots are prepared by ISO Technical Committee 299 with the title “Robotics”.

Safety standardization is a very important issue at ISO/TC 299. Safety standards have been developed for the industrial robotics sector (ISO 10218-1, ISO 10218-2, ISO/TS 15066) as well as for the non-industrial (service) robotics sector (ISO 13482). Other topics for robot standardization activities at ISO/TC 299 include: performance criteria, modularity, and vocabulary.

More information about ISO/TC 299 “Robotics” including a list of published standards as well as a list of standards under development can be found at the ISO webpage.

Main benefits of robot investments

The reasons why companies consider investing in a robot system differ widely. Some factors include the positive effect on parts quality, increase of manufacturing productivity (faster cycle time) and/or yield (less scrap), improved worker safety, reduction of work-in-progress, greater flexibility in the manufacturing process and reduction of costs.

Main reasons for investing in industrial robots:

- Increased flexibility to quickly adapt production and respond to changes in demand and smaller batch sizes

- Improved resilience to deal with production peaks and withstand systemic shocks such as COVID-19

- Energy and resource efficiency through optimized performance (reducing energy consumption, material waste and increasing yield)

- Improved productivity and support for manufacturing employees (Improving quality of work for employees, complying with health and safety rules)

- Reducing operating or capital costs

- Improving product quality

- Increasing production output rates

- Save space in high value manufacturing areas

Overall, robots increase productivity and competitiveness. Used effectively, they enable companies to become or remain competitive. This is particularly important for small-to-medium sized (SME) businesses that are the backbone of both developed and developing country economies. It also enables large companies to increase their competitiveness through faster product development and delivery. Increased use of robots is also enabling companies in high cost countries to ‘re-shore’ or bring back to their domestic base parts of the supply chain that they have previously outsourced to sources of cheaper labor.

Collaborative Robots

Collaborative industrial robots are designed to perform tasks in collaboration with workers in industrial sectors. The International Federation of Robotics defines two types of robot designed for collaborative use. One group covers robots designed for collaborative use that comply with the International Organization for Standards norm 10218-1 which specifies requirements and guidelines for the inherent safe design, protective measures and information for use of industrial robots. The other group covers robots designed for collaborative use that do not satisfy the requirements of ISO 10218-1. This does not imply that these robots are unsafe. They may follow different safety standards, for example national or in-house standards.

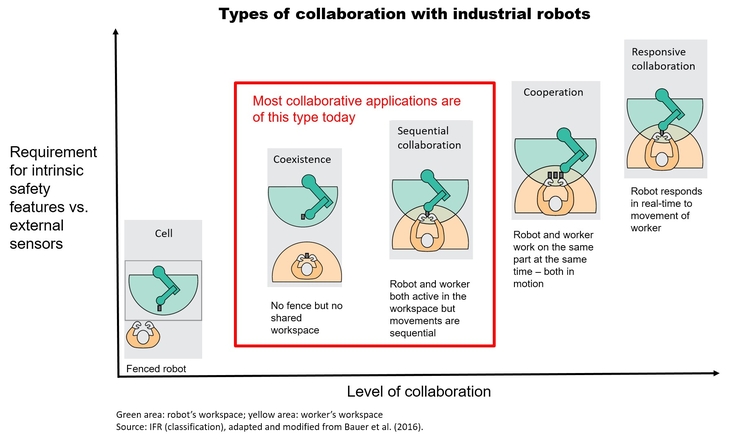

There is considerable variance in the types of collaborative robots meeting the above specifications, and the level of contact between robot and worker in collaborative applications. At one end of the technical spectrum are traditional industrial robots operating in a separate workspace that workers can enter periodically without having to shut off power to the robot and secure the production cell beforehand – a time-intensive procedure that can cost thousands of dollars per minute of machine downtime. The robot’s workspace can be fitted with sensors that detect human motion and ensure the robot works at very slow speeds or stops when a worker is within the designated workspace. At the other end of the spectrum are industrial robots designed specifically to work alongside humans in a shared workspace. Often referred to as ‘cobots’, these robots are designed with a variety of technical features that ensure they do not cause harm when a worker comes into direct contact, either deliberately or by accident. These features include lightweight materials, rounded contours, padding, ‘skins’ (padding with embedded sensors) and sensors at the robot base or joints that measure and control force and speed and ensure these do not exceed defined thresholds if contact occurs.

The market for collaborative robots is growing continuously. End-users and systems integrators are gaining experience on what works and doesn’t in the design and implementation of collaborative applications. More and more out-of-the-box solutions are available for standard tasks. Technology developments in sensors and grippers hold promise for expanding the range of actions that the robot end-effector can perform. Programming interfaces will continue to become more intuitive, not just for cobots, but also for traditional industrial robots.

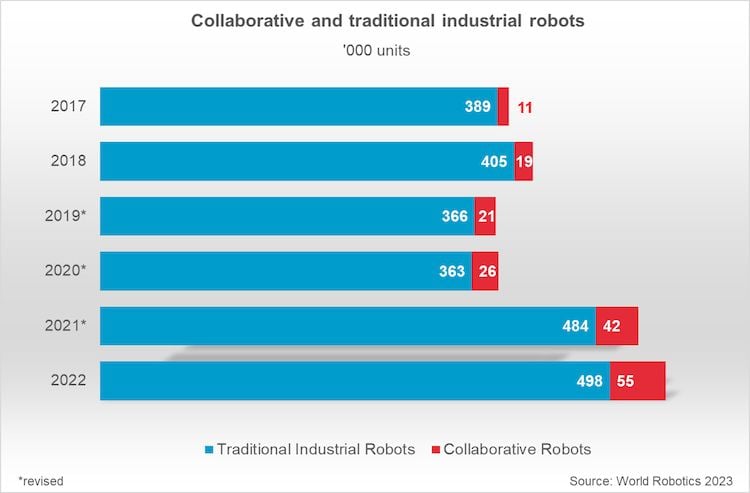

IFR is compiling an annual statistics on collaborative robots, which includes industrial robots that are designed and intended for collaborative use, in compliance with ISO 10218-1. In 2022, the number of newly deployed collaborative robots grew by 31% to almost 55 thousand units. This was 9.9% of the total industrial robots installed.

For more information, please refer to the IFR Positioning Paper on Demystifying Collaborative Robots and case studies.

Robots and AI

Artificial intelligence in robots gives companies new opportunities to increase productivity, make work safer, and save people valuable time. Substantial research is being devoted to using AI to expand robot functionality. Commercially available applications include the use of AI to:

- Enable robots to sense and respond to their environment: This vastly increases the range of functions robots can perform.

- Optimise robot and process performance, saving companies money.

- Enable robots to function as mobile, interactive information systems in numerous settings from public spaces to hospitals to retail outlets, saving individuals time.

For more information, please refer to the IFR Media Backgrounder on Artificial Intelligence in Robotics.

Smart, connected robots transforming manufacturing

The IFR has identified five common scenarios in which robots are connected within broader automation strategies:

- Automated production:

Linking the first stages of production such as order entry and product design to downstream processes such as parts ordering and machine scheduling enables manufacturers to immediately understand the resource implications of producing a new product or order and to better optimize the organization of production. - Optimizing performance:

Connecting robots and other machines to a central computing server enables manufacturers to extract and aggregate data that can be used to optimize machine performance in real-time or retrospectively, avoiding unplanned machine downtime which can cost manufacturers over $1 million per hour.

- Digital twins:

Virtual representations of robots and other production machines enable manufacturers to simulate operations and the impact of changes to parameters and programs before they are implemented, enabling improved production planning, and avoiding costly downtime. - Robots as a Service:

Adopting robots on a pay-per-use basis can be particularly beneficial for small-to-medium-sized manufacturers, sparing them up front capital investment and unpredictable maintenance costs, and giving them predictability of operating expenditure. - Sense and Respond:

Sensors and vision systems enable robots to respond to their external environment in real-time, expanding the range of tasks the robot can perform - such as picking and placing unsorted parts - and expanding robot mobility. Mobile robots are key to enabling flexible manufacturing, in which production is split into discrete processes and production cells running in parallel.

For more information, please refer to the IFR Information Paper on How Connected Robots are Transforming Manufacturing.