AI-equipped Robots Help Logistics Industry to Fight Labor Shortages

Different types of robots on hand

Autonomous mobile robots transport pallets from the depot to the warehouse, manned hightrucks take over © Mobile Industrial Robots

“Shortage of truck drivers, warehousing staff or dockworkers is a critical pressure on supply chain management worldwide,” says Marina Bill, President of the International Federation of Robotics. “By combining automation hardware with smart software, robot manufacturers deliver to the specific needs of the warehouse and logistics industry. AI-equipped robots offer tremendous new opportunities for this sector.”

AI-enabled robots learn to handle variability and unpredictability

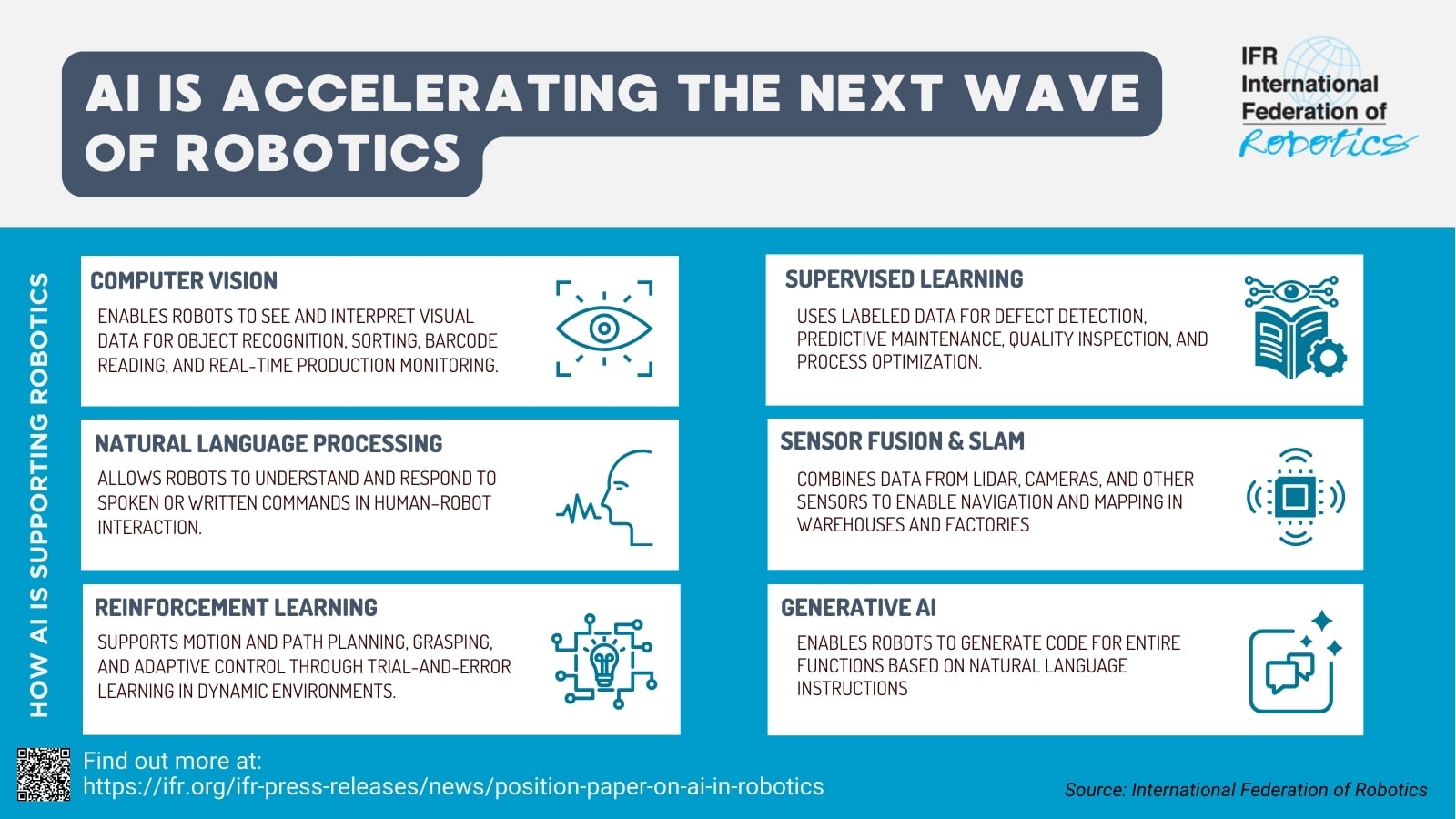

The main aim of using AI in robotics is to better manage variability and unpredictability: logistics providers deal with a mass market of cross-border shipping, e-commerce or last-mile delivery. This environment handles frequently changing products, orders and stock. To make machines capable of supporting such flexible workflows, AI software runs by experience, rather than programming. These AI-equipped robots learn to pick and pack different objects at high speed in a warehouse, use vision to transport items autonomously around the factory and provide AI-driven interfaces that turn a 90-minute maintenance task into a two-second adjustment.

Shortage of 3 million truck drivers

For many logistics companies, the time to further automate is now. The worldwide shortage of truck drivers is one of many reasons: according to the International Road Transport Union (IRU), there are currently over 3 million truck driver positions to be filled worldwide. With the huge demographic gap between young and old drivers growing, driver shortages are forecast to double by 2028.

While the overall challenge of labor shortage is common across the logistical supply chain in Europe, Asia and the US, specific reasons and severity differ. New worktime regulations by governments force companies in Japan, for example, to further automate. In the United States, a special shortage of skilled logistics professionals in e-commerce warehouses needs technological support and in Germany, keeping older workers in employment to physically demanding roles requires better workplace conditions for these colleagues.

“Robotics technology is a fit for various tasks within the logistics industry. While service robots work alongside human personnel creating more efficient workplaces, industrial robots help to automate dirty, dull and dangerous tasks behind fences. The combined power of a wide range of applications in robotics and automation will play a crucial role in addressing workforce gaps and allow future growth in this key industry,” says Marina Bill.

LogiMAT 2024 in Stuttgart, Germany – March 19-21

IFR members will showcase a broad spectrum of solutions for the logistics sector at the 2024 LogiMAT fair in Stuttgart, Germany.

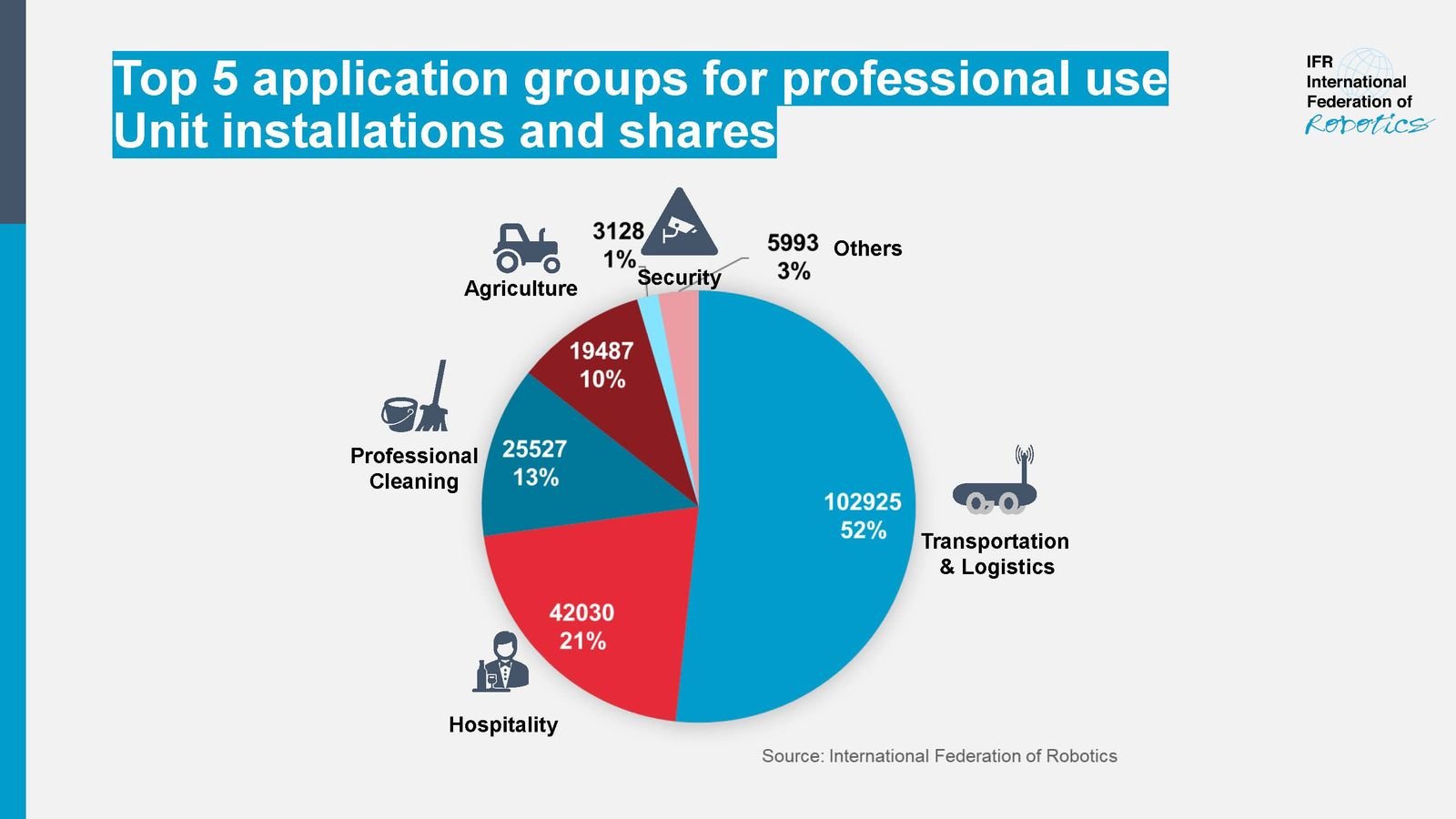

The annual report World Robotics - Service Robots compiled by the IFR Statistical Department provides an overview on the global service robotics market. It includes the results of the annual IFR service robot survey on global sales of professional and consumer service robots and an industry structure analysis including a full list of all service robot producers known to the IFR. The report also describes marketable products, tasks, challenges and new developments by service robots application.

The 2024 edition will in particular highlight the application areas outdoor transportation without public traffic, mobile guidance, information, and telepresence robots as well as robots for social Interaction, with expert interviews with leading suppliers and an in-depth market analysis. The study is jointly prepared with the robotics experts of Fraunhofer IPA, Stuttgart.

Press contact

PRESS OFFICER International Federation of Robotics

Carsten Heer

phone +49 (0) 40 822 44 284

E-Mail: [email protected]

Downloads

How Robots Help to Fight Labor Shortage And Create New Jobs - revised IFR-PAPER “Next Generation Skills”: https://ifr.org/ifr-press-rele...