Taking us closer to a decarbonized society

six minutes at a time

Sep 25, 2023 — In the time it takes to read this article, Absolicon, with the help of ABB robots, will potentially have taken the world one step closer to Net Zero with its innovative solar technology and newly automated manufacturing process.Climate change is an existential threat to our society. It is agreed by the vast majority that pivoting away from fossil fuels and towards renewable energy is vital to preserving resources and the natural environment and enabling the transformation to a sustainable society. Solar energy is one element of the overall energy mix, and for many countries and regions which enjoy comparatively high levels of sunlight throughout the year it is an ideal solution for decarbonizing the grid. However, a caveat with solar energy is its cost. Solar technology is traditionally difficult and expensive to both develop and manufacture on a mass level.

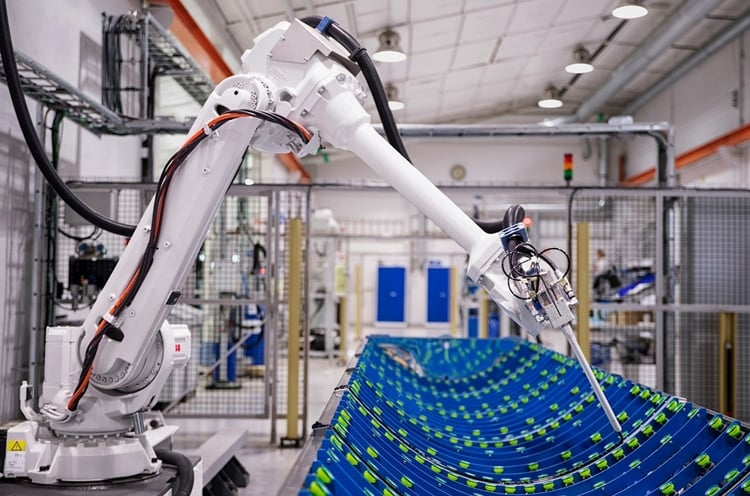

Thanks to the use of ABB robots, Swedish manufacturer Absolicon has developed what it sees as a gamechanger for the widespread adoption of solar as an energy source. The company manufactures solar collectors, which are essentially troughs which track the sun across the sky to catch its rays. A parabolic reflector focuses the solar irradiation on a receiver, which then turns it into heat, which in turn generates steam at up to 160 degrees. Absolicon’s solar collectors are the most efficient in their class and are ideal for industrial companies and district heating networks.

Almost all industries require heat for production processes. In textiles manufacturing for instance, almost two kilograms of coal are burned for every one kilogram of cloth produced. Beer production burns two tons of diesel for every 100 liters of beer. Even industries that are not widely considered to be energy intensive can require significant amounts of heat. Drying tea leaves, for example, requires the burning of five tons of firewood for every one ton of tea leaves. Solar collectors like Absolicon’s can harness the clean energy of the sun to produce this heat while generating zero CO2 emissions. To give some idea of their emission-saving potential, every square meter of a solar thermal collector can produce the equivalent energy of 100 liters of oil.

Solar collector panels are highly complex, requiring production processes that are extremely precise, highly efficient and cost effective. To achieve this, Absolicon and ABB have developed the world’s only complete solution for the mass production of concentrated solar collectors, in Absolicon’s factory in Härnösand, Sweden.

The degree of automation has increased production drastically. Where previously Absolicon was able to produce three solar collectors per day using manual production methods, with units assembled in the field, the newly installed robotic production line, which uses two ABB robots, has enabled the creation of an automated factory production line that is capable of producing a single collector in as little as six minutes. By the time you finish reading this article a new solar collector may well be ready for delivery.

The newly automated production process significantly reduces the skilled labour requirements and production cycle time for each collector, substantially reducing the overall unit cost. The consistent performance of the robots also enables each collector to be assembled in the same way, ensuring that the highest levels of quality are maintained throughout production and that the assembled collectors can offer optimum performance once installed.

Crucially, Absolicon has not just developed the solar collector itself, but intends to export the whole robotised production unit as a turnkey solution, so that collectors can be manufactured locally. This could have significant ramifications for the solar industry, making advanced solar technology both more affordable and more accessible for companies, organizations and governments across the world.

"Developing an automated production process enables our global business case by radically reducing the price of our solar collectors, while manufacturing them consistently to a very high quality. The productivity offered by ABB’s robots means we can make solar energy compete on price with conventional industrial heating for the first time," says Joakim Byström, CEO of Absolicon. “Our new automated production line can produce a complete solar collector every six minutes, so while competitors rely on a manually intensive manufacturing process, we can now do it with five people, two robots and a fraction of the components. This will be key in helping to meet the growing demand for renewable technologies to help meet global carbon emissions reduction targets.”

“We are pleased that ABB’s robotics solutions are accelerating the productivity, quality and cost efficiency of Absolicon’s production line to enable them to bring a renewable energy product to market at a competitive price,” says Sami Atiya, President of ABB’s Robotics & Discrete Automation Business Area. “In helping Absolicon to accelerate their production from three units a day to one every six minutes, our robotic solutions are playing a key role in accelerating the global adoption of sustainable technology, ensuring Absolicon’s production partners are able to consistently produce solar collector panels globally.”

The next phase of the project involves supplying complete robotic production lines to manufacturing partners across the globe and ABB and Absolicon have agreed they will collaborate on the development, sales and marketing of the robotic production line worldwide.

“Our vision is to enable a cost-effective mass-production of solar collectors across the world, to produce heat directly from sunlight,” adds Byström. “Our work with ABB to create this automated production process is a key enabler to realize our vision, while ABB's global service organization will be a very valuable resource for our new customers as we roll-out our new automated production line globally.” The first installation has already been delivered to a partner in China, and framework agreements for the acquisition of robotic production lines have been signed with businesses in a dozen countries, with ABB supplying the robots for all new installations.