Case Studies / Industrial Robots / How Connected Robots are Transforming Manufacturing / AI in Robotics

Smart 3D Vision Solutions

How 3D vision solution brings benefits to robot depalletizing for retail industry

May 19, 2021 — In order to boost efficiency and maintain its competitiveness in logistics distribution and retail supply chain within specific region, LQ invested high level of warehouse automation.

One of the depalletizing cell under commissioning © Mech-Mind Robotics Technologies

LQ Group is a giant trans-regional and comprehensive commercial group in FMCG industry, and it is one of the top 500 enterprises in China. LQ had traditionally used conventional human-operated warehouse system.

In order to boost efficiency and maintain its competitiveness in logistics distribution and retail supply chain within specific region, LQ invested high level of warehouse automation. At the near end of the system, four depalletizing cells with ABB IRB660 are designed to pick specific number of cartons according to the orders.

There is only one kind of cartons on each pallet; however, there are thousand kinds of cartons with various sizes, colors, patterns, shades, and etc. to be processed everyday which are not able to be handled by conventional robot solution. To solve these problems, Mech-Mind 3D vision system provided an alternative to ABB robot.

Requirement for the vision system

examples of cartons colors and cartons shape © Mech-Mind Robotics

Comprising with Mech-Mind industrial 3D camera, vision system (Mech-Vision), and code-free robot programming system (Mech-Viz), the automated solution aimed to reach 1000 cartons/hour for one robot station, the cycle time between each pick is 10s, which means the vision system should also support for picking three cartons at one time pick.

The Mech-Eye deep is mounted on a stand 1700mm above the top of cartons.

The max weight of one carton is 30 kg.

The FOV (field of view) is 1000*1200*1300 (length*width*height).

The recognize accuracy of vision system should be larger than 99.99%, the time consuming of the visions system should be within 2s and the locating accuracy is±3mm. The vision system is perfectly compatible with ABB robot and the communication protocol is TCP/IP.

The vision system should determine the coordinates and the pose of the cartons which should be picked; therefore the path planning and collision detection of the robot can be taken care of.

Multiple sizes and colors cartons for FMCG (length:600~300mm,width: 500~200mm,height: 500~200mm)

Automating procedure of the depalletizing cell

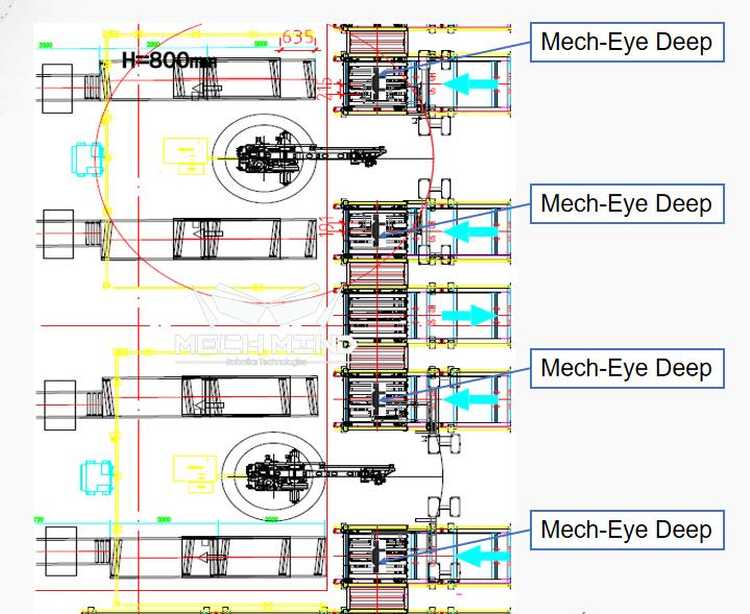

Arrangement drawings for two cells © Mech-Mind Robotics Technologies

In order to reduce the downtime of waiting for new pallets, two cameras are installed on the left and right of the conveyor and guides the robot to execute the order alternatively. The pallets are conveyed to the left and right of the depalletizing station. Once the pallet arrives at a certain position, the host control system sends the signals of the cartons on the pallet including size, weight and quantities to the robot.

As soon as the robot receives the arrival signal from the host system, it triggers the camera to take a picture and sends the picture to Mech-Vision. The vision combines the coordinates and poses of cartons into grasping points and sends it to Mech-Viz.

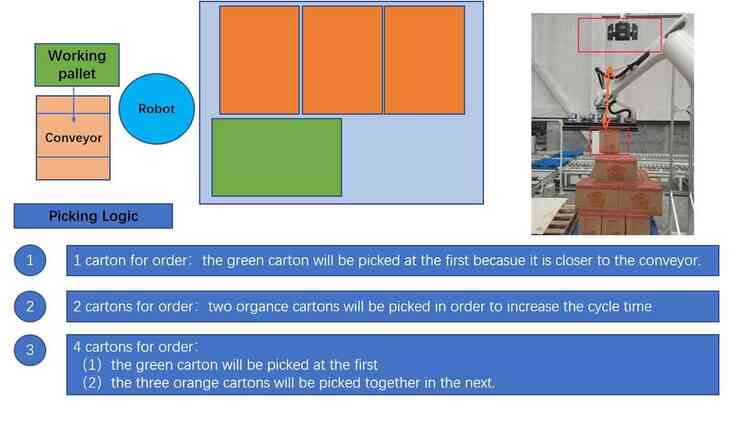

The Mech-Viz receives the order information and grasping points, afterwards, it guides the EOAT on how many suction cups have to be activated in order to pick a specific number of cartons and which specific cartons have to be picked on the same layer; moreover, Mech-Viz should also inform the robot of the cartons direction when it is put on the conveyor.

Repeat the procedure.

Illustrate the picking logic for the depalletizing cell © Mech-Mind Robotics Technologies

The intelligent solution

The key element of LQ depalletizing solution are Mech-Mind industrial 3D camera, graphical machine vision software and intelligent code-free robot programming environment.

- Complete and rich function package of 3D vision solutions including hardware, vision system and robot programming.

- Stable and reliable hardware (passed 7000 hours endurance test)

- Advanced algorithms with deep learning, able to handle various complicated situations.

- Fully automated calibration with high accuracy.

- Fast and accurate object locating.

- Code-free programming environment.

- Fully visualized interface with only one-click simulation of robot movement

- Simple and intelligent software with ensuring the stability of robots in the meantime.

- Adaptable to various mainstream robot brands.

- The cameras and vision system are implemented with robots within 2 weeks.

How the vision system improves the robot depalletizing

- Highly improved flexibility of robot, by putting intelligence into robot and guiding the robot to solve complex tasks in a much easier and cost-effective way compared to conventional robot station.

- Higher production capacity provided by code-free robot programming system, can support multiple suction cups on the EOAT to handle multiple cartons at the same time.

- Robust, the advanced vision algorithm can still identify cartons with unfavorable conditions such as binding, reflection and tightly packed objects.

- Thanks to the advanced deep learning algorithm, all types of cartons can be recognized, and there’s no need for registration.

- Saving a lot of deployment time and reducing the usage difficulty and deployment costs

- Lower maintenance rate compared to conventional way due to less simple structure, less part, code free environment