SCHOTT AG automates quality inspection with OnRobot

Sep 21, 2022 — Even back then, Otto Schott was considered a pioneer in the science of glass, and SCHOTT AG, the company he founded, continues to break new technological ground today.

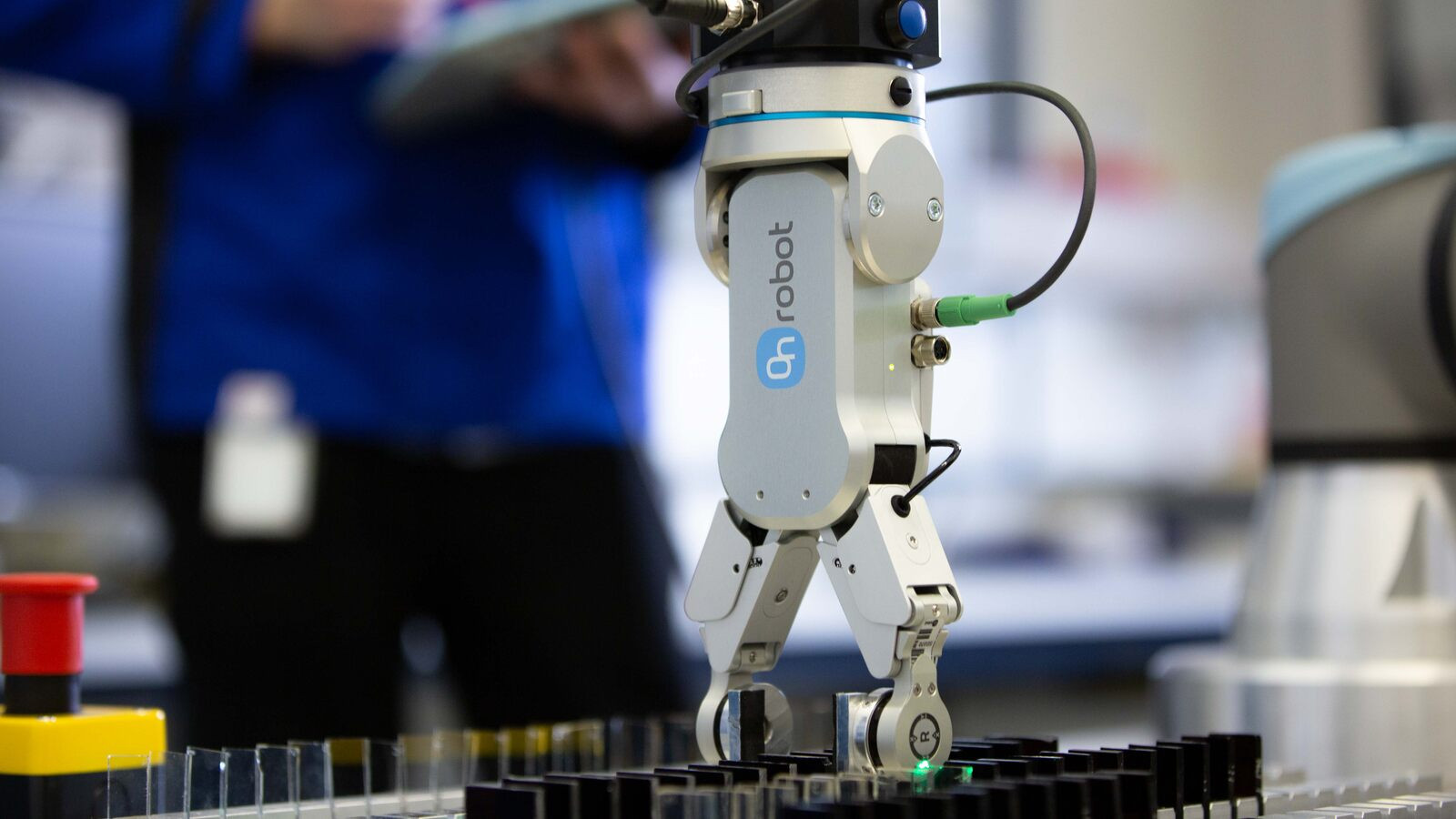

RG2-FT gripper from OnRobot is mounted on a collaborating robot arm (copyright: OnRobot)

Even back then, Otto Schott was considered a pioneer in the science of glass, and SCHOTT AG, the company he founded, continues to break new technological ground today. In the glass laboratory of its Mainz research center, the international technology group uses a collaborative application for quality testing - and in doing so relieves the laboratory staff of more demanding tasks. This gives SCHOTT more capacity for development projects and enables it to efficiently handle the growing volume of samples. This is made possible by a gripper from OnRobot. Thanks to integrated sensors in its fingertips, the RG2-FT can handle individually shaped glass samples and operate highly sensitive measuring instruments.

Whether in aerospace, medical technology or the automotive industry: The diverse products of SCHOTT AG are used in almost all areas of life. The technology group with its focus on glass and glass ceramics has been producing new innovations for 130 years. At that time, company founder Otto Schott initiated the special glass industry as a separate branch of industry by using novel manufacturing processes to develop glasses with precisely defined properties for the first time. Since then, Schott has considerably expanded the range of applications for the material over the years.

Technology pioneer SCHOTT: always one step ahead

In keeping with its founding idea, today's SCHOTT AG is also always operating at the limits of what is possible and is continuously expanding this through technological progress. The SCHOTT Research Center in Mainz plays a key role in this process. In the glass laboratory there, employees test glass samples for their physical properties. Through their measurements, they generate data that are incorporated into the company's numerous research projects. On the other hand, they regularly test samples from production.

"The material that is processed has to meet very specific specifications to ensure that a flawless product is ultimately created," explains Dr. Axel Engel, Senior Manager Physical Analytics at SCHOTT. "This ensures high product quality and helps to reduce waste." For example, when it comes to ceramic glass for hotplates or glass for fireplace doors, it must not be allowed to deform under any circumstances when exposed to heat. "Quality control is therefore very important for the entire manufacturing process." Today, SCHOTT automates part of this step with the help of a collaborative application using a gripper from OnRobot.

Challenge: Increasing number of samples

The impetus for this was a sharp increase in the number of samples that have to be tested for research purposes. "In the last three years, the volume of samples here in the laboratory has increased by about 30 percent," reports Dr. Engel. This posed several challenges for the manager and his team: SCHOTT needed more capacity to test so many samples in the time available. However, additional measuring equipment and personnel would only have limited space in the limited laboratory space. In addition, it took the employees a lot of time to load the measuring device. A measurement takes between three and 15 minutes, after which the employees have to interrupt other activities in order to insert a new sample. This is where the idea of automating the measuring process first came up.

Gripper with a sure instinct needed

"We put a lot of time and effort into selecting a suitable automation solution," recalls Dr. Engel. "The solution had to be space-saving and be able to work right next to the laboratory technicians. A conventional industrial robot was out of the question: it would have needed an additional protective enclosure, and there is no room for that". There was also another difficulty: the measuring device, a so-called transmission spectrometer that records the optical properties of the glass, is extremely sensitive. Inserting the samples in such a way that the expensive device is not damaged requires great sensitivity. "After looking at solutions from various manufacturers, we finally found what we were looking for in OnRobot," reports Dr. Engel.

SCHOTT decided on an application in which an RG2-FT gripper from OnRobot is mounted on a collaborating robot arm. The special thing about the electric two-finger gripper is that both force/torque sensors and optical sensors are located in its fingertips. These enable him to "think along": The sensors feed their process data back to the robot arm, which adjusts its course accordingly. This enables the gripper to precisely meter the force applied to the arm. This gives the application as a whole the necessary sensitivity to load the spectrometer with millimeter precision.

Application relieves employees

"With the help of its sensor technology, the gripper is able to identify the position of objects and grip them in the center without knowing the exact parameters in advance," explains Florian Grabowski, Project Engineer at SCHOTT. "In this way, it can also efficiently support the measurement process." For this purpose, the glass samples are lined up next to the application in a holding fixture, the so-called tray. On their sides are barcodes that the RG2-FT uses to identify which sample it should pick up next. The RG2-FT is coupled with the software of the measuring instrument for this purpose. Thus, it knows which sample is to be measured next. He picks up the corresponding sample and places it in the spectrometer, where it is clamped in a pneumatic cylinder. Then the measurement begins. The robot then automatically removes the sample and places it back in the tray.

Physics laboratory technician Nicole Mück used to operate the spectrometer manually. Now she benefits directly from the new application. "I have more time for documentation tasks, for example elaborate test reports," says Mück. "I can use the spectrometer more for more complex measurements involving test objects of different shapes and sizes - this is more complicated and requires me to process the samples myself. The application can continuously load the measuring device. This means it can work overnight and on weekends without a break. As a result, the robot has already handled a large part of the sample volume when Ms. Mück and her colleagues start their working day.

Intuitive operability

SCHOTT worked closely with OnRobot and the local system integrator Fichtner to integrate the gripper and robot arm, as project engineer Grabowski reports: "We were in active communication with both OnRobot and Fictner during implementation. We also developed special fingertips to optimally adapt the application to our requirements. These consist of aluminum and are coated with foam rubber. The background: The glass samples are handmade at SCHOTT so that each sample is individual. "With the help of its sensor technology and the adapted fingertips, the RG2-FT can still grip the sample glasses perfectly," Grabowski explains.

The robot arm and gripper can be controlled via an intuitive user interface that the team accesses via a tablet. "The interface is clearly structured so that it is easy to find your way around," explains Grabowski. "Even users without special programming skills can easily assign tasks to the robot".

Extending automation

Dr. Engel is satisfied with the pilot project: "With the application we can work much more efficiently and relieve our employees," he sums up. Thanks to the rapid integration and smooth processes, the application also promises a rapid ROI: "We expect the purchase to pay for itself within five to six months".

Soon, SCHOTT also wants to use collaborative applications in other areas of its internal value chain. One conceivable area would be glass processing, for example, where many process steps, such as drilling, milling or grinding, are currently still done by hand. With collaborative applications, such tasks can already be automated cost-effectively today. In this way, SCHOTT is making itself fit for the future and focusing on always be one step ahead of the status quo.