Pioneering robotic Approach for Complex Assembly Process

Automated with AI

Aug 06, 2025 — As part of a development cooperation between Schaeffler and AICA, an AI-empowered automation solution utilizing Cobots has been industrialized, which, in addition to direct automation of a complex assembly process, also optimized the efficiency of automation engineering.

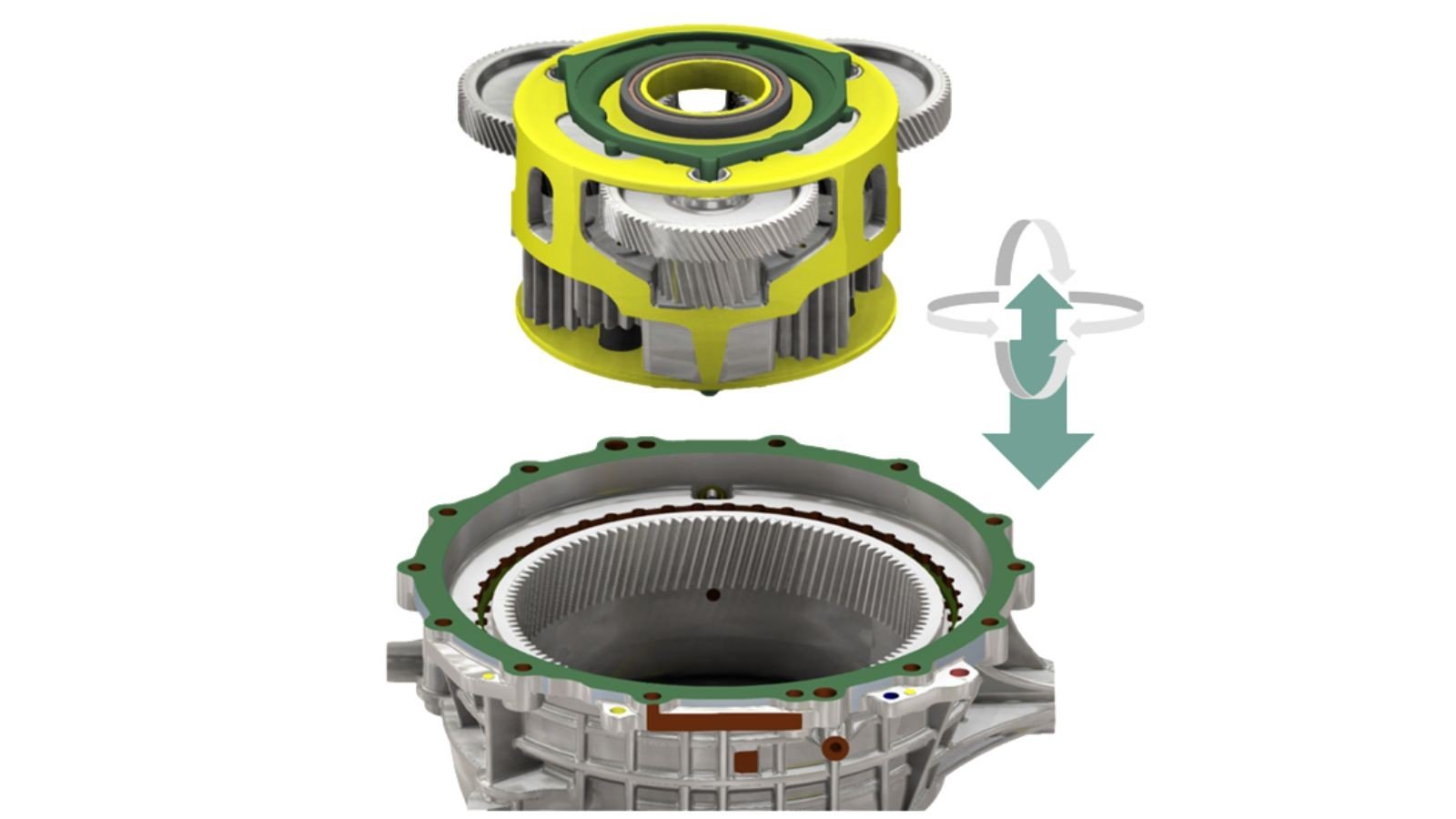

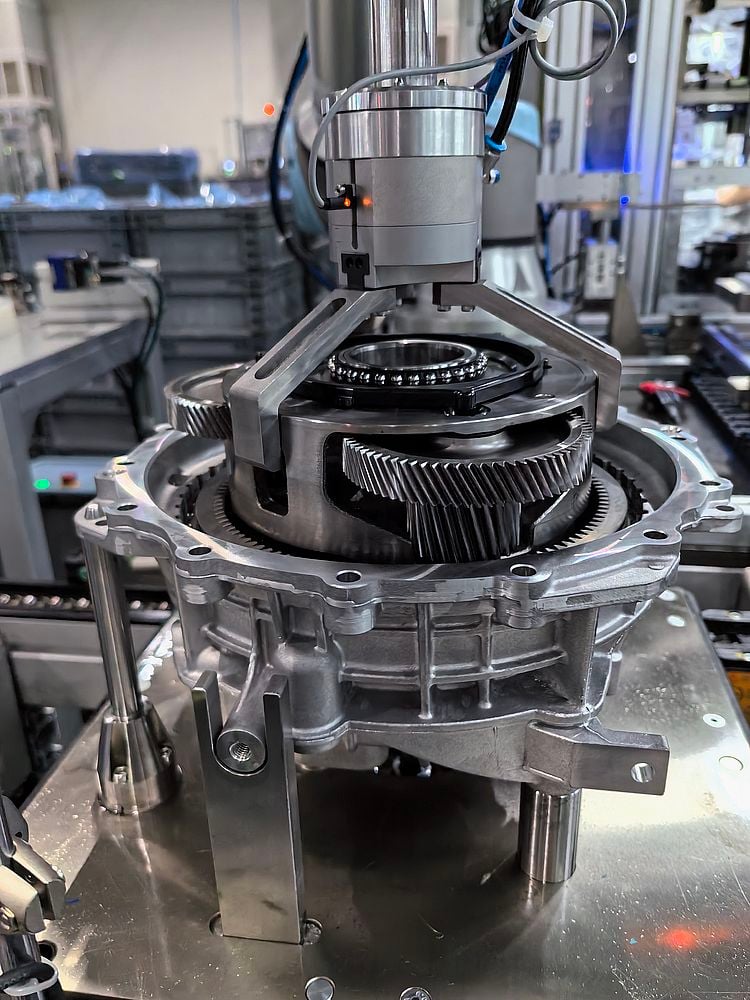

Complex gearbox assembly in the field of E-Mobility at Schaeffler - Image Copyright: Schaeffler Technologies

AICA Smart Assembly

Manufacturing companies are currently operating in a volatile market environment characterized by shorter product and technology life cycles and reinforced by a transformation towards more sustainability. As a result of the increasing scope of functionalities and degree of individualization, products as well as the associated productions are becoming more complex. Additionally, the progress of demographic change involving more and more regions globally brings further tension in manufacturing due to increasing lack of skilled employees.

New solutions in the field of complex assembly automation are necessary to accelerate the speed of adaption towards an efficient and flexible automation for cost-optimized production.

As part of a development cooperation between Schaeffler and AICA, an AI-empowered automation solution utilizing Cobots has been industrialized, which, in addition to direct automation of a complex assembly process, also optimized the efficiency of automation engineering. Within the first use case for the assembly automation of a planetary gear box in the field of E-Mobility the following key features and benefits arise.

Key Features & Benefits:

- Seamless integration with existing systems.x

- Real-time adaptation to changes in the production environment.

- Autonomous learning from force feedback.

- Improved productivity and efficiency.

- Enhanced precision and accuracy.

Gearbox Assembly Challenges

With the transformation towards system products in e-mobility and the increase of complex assembly tasks, Schaeffler strived to enhance the efficiency and accuracy of automated assembly processes to fulfill the requirements for precise assembly in a specified time. Up to now the robot automation for the assembly of gearboxes with conventional programming approaches represents a major challenge with high engineering costs and efforts in making production reliable. This is caused by the complex matching process of multiple, independently rotating and helically toothed planets with the helical ring gear of the housing. In addition, the tolerance range in weight, size and shape of the workpiece affects the process.

Ultimately, a new approach in robot programming should make it possible to overcome the challenges and implement new use cases as autonomously as possible with a minimum effort.

This is how the collaboration with AICA, a Swiss robotics company, was initiated. AICA itself is specialized in the development of software for the automation of complex assembly processes by using a reinforcement learning approach, a subfield of machine learning.

AICA's Cutting-Edge Solution

As part of the development cooperation between Schaeffler and AICA, AICA has tailored its state-of-the-art robot software to Schaeffler’s specific requirements and use cases. The software module ‘Smart Assembly’ uses real-time adaption, force feedback and autonomous learning capabilities (reinforcement learning) to optimize the assembly process. As a result, the robot independently and autonomously trains the optimum assembly parameters based on previously defined framework conditions and success criteria.

Significant benefits for Schaeffler achieved to date:

- #1 AI-empowered automation solution for assembly in series production use.

- More than 30% reduction of the development time.

- No dedicated expert knowledge required for robot programming.

- Hardware-agnostic solution.

International technology rollout and first successful industrialization in series production – Automotive E-axle assembly

As part of Schaeffler’s industrialization efforts to transfer the AI-empowered automation solution from AICA into series production, a use case in the field of e-mobility in the region Greater China was identified by the international production technology and innovation network. In cross-regional and cross-functional collaboration with the business unit and driven by the established ‘Advanced Production Technology’ function, the technology was enabled for use in series production.

The use case focuses on the automation of a helical planetary gearbox assembly, which is used as a subsystem in an e-axle drive system for electric vehicles. The challenge in the assembly process arises from the helical gearing of the three planets and the ring gear in the housing as well as the independently rotating planets (before assembly), which consequently have different initial positions themselves and in relation to each other.

Decisive steps in the systematically structured innovation process were the core technology development and adaption to Schaeffler-specific use cases in series production, followed by an international technology rollout. In cooperation with the business unit, proof of concept was performed in dedicated innovation centers with various designs and in addition the technology was finally qualified via a long-term test lasting for several months. This also included the detailed process and progress monitoring of the use-case with a monitoring software platform developed inhouse. In the end the solution was fully handed over to production in Q4/2023.

The advantages of the AICA solution were proven in various dimensions. On the one hand, the necessity of direct operators in the production line can be reduced due to assembly process automation. In addition, the engineering efforts to generate the planet carrier insertion trajectory can be minimized by the AICA solution through the reinforcement learning approach which runs autonomously compared to conventional robot programming. Furthermore, the necessary qualification level of the engineer to generate the use-case specific trajectories is much lower in contrast to conventional robot programming which leads to higher speed in terms of international technology roll-out und multiplying of use-cases.

In conclusion, the AICA solution already offers quantifiable potential after the first months of mass production implementation, and the scaling of the technology will continue in the region Greater China as well as in the rest of the Schaeffler world based on the positive results of this first use-case.

Successful Implementation & Positive Outcomes

The success of this partnership shows that many industrial challenges can be solved using adaptive force control and learning. AICA’s modular software blocks allowed the teams to iterate and refine robot applications at a fast pace.

As part of this collaboration, the two companies have additionally implemented the solution on collaborative and industrial robots incl. evaluations and optimizations. Schaeffler and AICA are currently working on further projects with the aim of improving complex process automation in the automotive and industrial business divisions. Furthermore, AICA is developing new products as part of its long-term strategy to enable its customers to benefit from machine learning and solve some of the world’s most challenging automation tasks.