KUKA robots with camera systems automate the production line at Danfoss

Jun 19, 2024 — Masterpiece of 3D perception: robotic systems recognize and move more than 100 different components at the Danish company Danfoss.

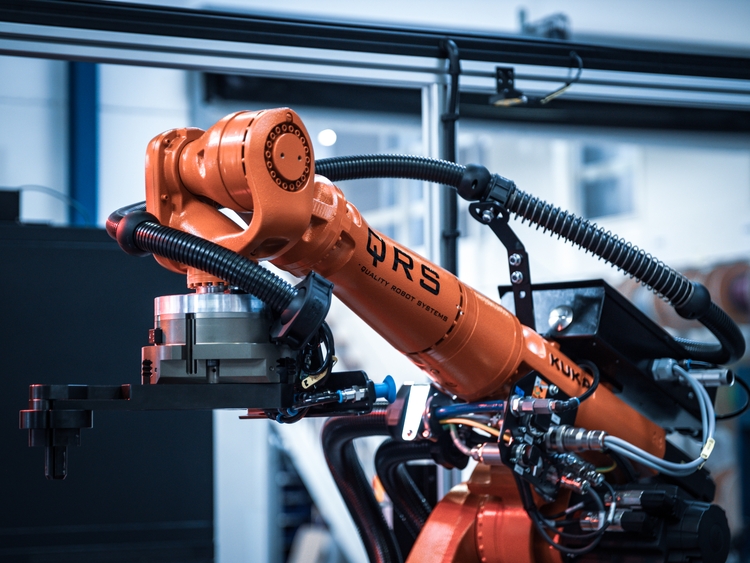

Masterpiece of 3D perception: KUKA, Roboception and QRS automate the production line at Danfoss © KUKA

At Danfoss, a Danish manufacturer of mobile hydraulics as well as electronic and electrical components, KUKA, QRS and Roboception are keeping the action mov-ing. Multiple robotic systems with 3D sensors reliably and precisely recognize and move over 100 different components. The three partners solved the numer-ous challenges together – with their valuable expertise and tireless commitment.

The artificial eye is never wrong

The camera performance of the new robotic cells with artificial eyes at Danfoss is definitely a contender for the “Masterpiece of 3D perception” award. This is because the system recognizes more than 100 different components in the production facility. It ensures that the KUKA robots in the cells of the Danish mobile hydraulics manufacturer efficiently and fully automatically load and unload machines in the production process.

With their new automation investment, the Scandinavians are precisely in tune with the Danish zeitgeist. This is because the northern Europeans already rank 6th in the world in terms of robot density in the manufacturing sector. It comes as no surprise that KUKA actively supported the project with its expertise. After all, the automation specialist supplies most of the robots in Denmark.

The camera recognizes more than 100 components

In the new production line at Danfoss, a total of six KUKA robots take over work steps that were previously performed manually. They move components weighing between 5 and 20 kilograms each. Automating this process reduces the physically demanding work for the team, allowing employees to take on more value-added tasks.

The robotic cells thus move up to 100 different components without manual intervention. “That was the major challenge in this project,” explains Olav K. Sjørslev, Sales Manager at integration partner QRS. “The requirement for the robotic cells at Danfoss was fully automatic feeding of the components – a task that can only be solved with a camera system, given the large number of variations.”

The alternative, namely feeding the blanks meticulously ordered and aligned, was simply not economically feasible. Instead, the components arrive at the first robot station in standard roll boxes, sorted by box, but with the boxes stacked on top of each other more or less indiscriminately, and with the layers of components separated by paper sheets.

3D stereo sensor rc_visard reliably provides the KUKA robots with the gripping points

“Our experience with camera systems in the past was not particularly good,” recalls Sjørslev. “We looked into various systems over the past decade, but did not find a single 3D vision solution that met our needs.” What works at a trade fair or in a manufacturer’s demonstration room is often not viable under real-world conditions, the sales manager emphasizes.

In solving this problem, QRS was able to benefit from its close partnership with KUKA, which has been in place for a good 15 years: When it comes to camera systems, KUKA turns to Munich-based partner Roboception, which offers not only a reliable 3D stereo sensor in the form of the rc_visard, but also develops modular software components that are ideally suited to applications such as those of Danish company Danfoss. “Using our SilhouetteMatch software, the rc_visard recognizes components on the basis of a tem-plate created either from CAD data or from data generated directly by the sensor,” ex-plains Dr. Michael Suppa, CEO of Roboception. Interaction with KUKA robots is very quick and easy using a standardized web interface and graphical user interface.

What this means in the case of Danfoss is that the rc_visard reliably detects the position and orientation of the flat, unordered objects on the flat paper surface and also provides the robot with the gripping points at the same time.

“A 2D solution was quickly ruled out for this project,” explains Suppa. “The paper slipsheets are not always completely flat, or may even be oily due to the components.” In tests with other systems, the camera had sometimes misinterpreted impressions as workpieces. The Roboception software, on the other hand, recognizes exactly which components are supplied to the robotic cell and transmits the appropriate gripping points for a KR CYBERTECH from KUKA. This removes the workpiece and takes it first to a marking laser.

The components then pass via a conveyor belt into another cell, where a KR QUANTEC automatically loads them into the grinding machine and unloads them again. In the subsequent cells, KR CYBERTECH robots feed the machined workpieces to a “washing system”, sort them into containers or load another small grinding machine.

Exchange of expertise among the parties involved

For those involved, the project was very much a case of jumping in at the deep end. “Implementation of the perception solution was a new experience for us. When we venture to take on something like this, we only select partners of whom we are absolutely convinced and who we are sure will support us in the long term,” emphasizes Olav Sjørslev from QRS. He has only positive things to report about the cooperation with Roboception and KUKA. “For this project, everyone involved willingly went the extra mile in terms of transfer of know-how and time invested.” But the effort was worth it in many respects. In this way, not only was the client satisfied, but the successful integration of the camera system from Roboception also ensured direct follow-up orders at integrator QRS.

“We learned a great deal from this job that will help us to realize other projects,” says Sjørslev. “What is the influence of light conditions, what interference can occur on the lens, how far away can parts still be recognized? We now have concrete answers to these questions.” Danfoss, too, is pleased with the solution from KUKA, Roboception and QRS. The automation not only accelerates and stabilizes the hydraulics expert’s production processes, but simultaneously ensures greater safety at work for its employees.

Pioneering solutions for customer and integrator

There is another important point to be made: “By integrating other software modules, our hardware can solve a wide variety of tasks,” says Dr. Michael Suppa of Roboception. “Danfoss thus now has a variable 3D vision solution that can be easily adapted to other tasks as required.”