How to Increase Your Robotic Cell Utilization

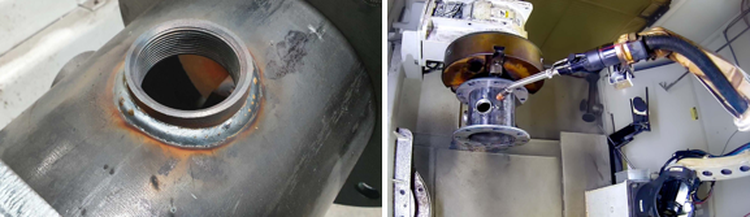

Feb 05, 2024 — ABAGY has retrofitted a robotic cell for Schenck Process, one of the global leaders in applied measuring and process technology.The robotic cell had already been operating at the Sabetha Kansas production facility (USA). It’s included Panasonic Robot and a two-in-one 1-axis positioner for a quick parts changeover. However, before ABAGY, it was used for a limited number of parts, as the programming was tedious.

ABAGY has installed machine vision and other hardware and made it compatible with its proprietary software. As a result, the setup time has been reduced dramatically - only 10-15 minutes for a new product - and the robot can be used for much more products. That’s a big win for Schenck Process with its high-mix production.

How It Works

Thanks to new technologies such as AI and machine vision robots become autonomous. They can see the part and understand the task. Workflow simplifies significantly. Robot cell control no longer requires programming skills.

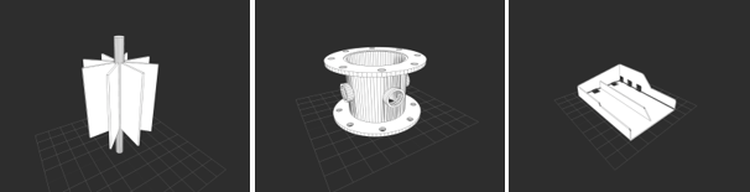

The employees upload a 3D model of the part (from the CAD). The system automatically finds the weld joints on it. Then they choose the welds and the parameters they need (work and travel angles, offsets, weaving, etc.). No programming is required. Mathematical algorithms automatically generate the robot trajectories. This happens in minutes.

The next step is scanning the part using machine vision. The algorithms compare the previously uploaded 3D model and the real part. The system finds possible deviations and adapts the robotic path on-the-fly.

What Changed for Schenck Process

- Any Products

Schenck Process uploaded 150 different part models into ABAGY software during the year.

Examples of products © Abagy - More Complex Products

A relief valve with its pipe-in-pipe design was previously welded manually. The robot could not weld such a product as it required complex programming. With ABAGY, robotic welding became possible, as programming and running the job is almost 100% automatic.

Examples of products © Abagy - Programming Time Is Reduced by Up To Ten Times

Previously, programming a robot for one part took about 1.5-2 hours, that is, 90-120 minutes.

Now it takes 9-10 minutes (for example, for a rotor with 18 welds). - One Program for Two Working Areas

There are two working zones in this cell. Before the retrofit, a separate program was needed for each zone. Now it is enough to create one technical chart for the product, and it will work for both areas. - Free Part Placement in The Working Area

Previously, Schenck Process had to measure everything with a ruler when installing each of the parts. Any, even small, deviation would lead to rework. Now, with ABAGY, deviations are tolerated. - Weld Quality

ABAGY software provides enhanced integration with the welding source, which makes it possible to use more advanced weld parameters and achieve better results. - Reduced Robot Downtime

Previously, programming with a teach pendant meant that the robotic cell had to stay idle. Now they can set a new task for robots as the cell is working on another project. - Operator-Friendly Interface

Previously, only one specialist could work with the robotic cell. Now different employees can control the robots.