Donk Industries Automates Machine Loading with OnRobot

Step by step to automation success

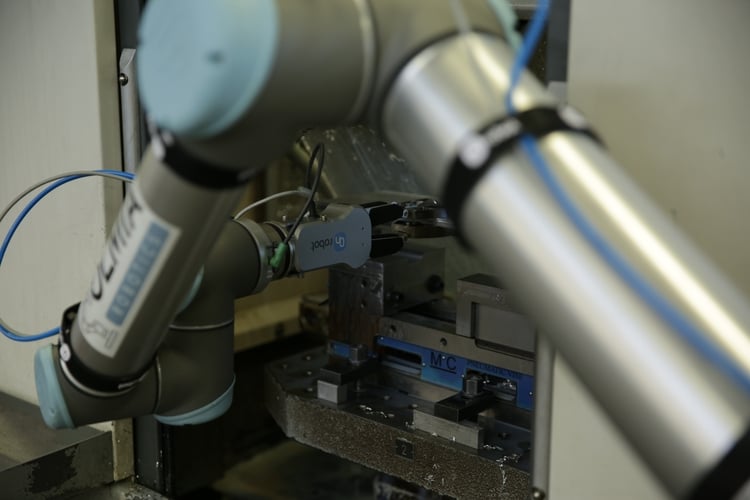

Sep 26, 2023 — When the Donk Industries employees enter the factory hall in the morning, their new colleague has already taken over the night shift for them: Since 2018, an RG6 gripper from OnRobot has been automatically feeding one of the eight CNC machines of the aluminum manufacturer with workpieces – around the clock.

To handle individual products, Donk Industries has developed special gripper tips that employees can mount to the OnRobot RG6 in just a few minutes. ©OnRobot

For the employees, this means an enormous relief, which opens up the opportunity to devote themselves to more demanding tasks. In addition, the company benefits from more efficient processes: The collaborative application has doubled the outcome of the CNC machine and ensures higher and more stable product quality.

Founded in 1932, Donk Industries is one of the largest small series manufacturers in the Benelux countries. At its site in Lopik, the Netherlands, around 100 employees produce aluminum parts of all kinds for Dutch and international customers. The foundry, powder coating plant, CNC machining department and product development are all located under one roof. The handling of all processes at one location is a logistical advantage both for the customers and for Donk Industries itself: customers only order from one supplier and receive the requested product assembled. This enables Donk Industries to respond optimally to customer requests.

The challenge of a shortage of skilled workers

But this service also comes with it challenges: As a single-item and small-series manufacturer, Donk Industries is confronted with a wide variety of products. At the same time, the company must keep its inventories low and supply customers on time. "In order to stand up to competitive pressure and meet the requirements of a small series manufacturer, we need qualified personnel," says Jaap Zentveld, Assistant Production Manager at Donk Industries, describing the situation.

In recent years, however, the company has been increasingly confronted with a shortage of skilled workers. It was particularly difficult to find personnel to operate the CNC machines - after all, this is a monotonous and time-consuming, yet less demanding task. Long cycle times cause long breaks, which the personnel spent waiting. "Employees who actually have other areas of responsibility were tied to the CNC machine," explains Zentveld. "This also had consequences for the quality and delivery reliability of the products.“

Flexible automation solution needed

Zentveld began to look for suitable automation solutions in order to deploy its employees more effectively and thus increase productivity while maintaining the same high-quality standards. The company looked at various robotic solutions and found collaborative robots among them. "We are already automating many other parts of the production process with industrial robots," says Zentveld. "However, we have to be flexible with our product variety and the small quantities involved and be able to convert our production lines quickly. In addition, Donk Industries' individual products require special handling. Collaborative applications meet these requirements in particular: They can be flexibly converted for new tasks and are easy to program. In contrast to conventional industrial robots, the combination of Cobot and corresponding end-of-arm tooling can be used directly next to humans and works directly with them.” Zentveld and his team therefore selected a collaborative robotics application with end-of-arm tools from OnRobot.

Gripper equipped CNC machine

Today, an RG6 gripper loads and unloads one of the eight CNC machines in Donk Industries' production halls. The gripper is mounted at the end of a collaborative robot arm and is combined with an OnRobot HEX sensor. This force/torque sensor provides the necessary sensitivity so that the gripper can grip workpieces precisely and perform its tasks efficiently. A specially designed loading station, the Robobooster4000 developed by system integrator Olmia Robotics, is a requirement for smooth loading and unloading of the machine. The gripper removes a component from this station and inserts it into the machine. After the milling process, it takes the finished product out and places it in the magazine. The cycle is repeated until all components have passed through the process.

Thanks to the individually adjustable fingertips, the OnRobot gripper can handle objects of different shapes and sizes. The local partner Olmia Robotics helped adapt the robotics solution to Donk Industries products. "With Donk Industries' specific requirements in mind, we recommended an OnRobot gripper," said Peter van Olm, founder of Olmia Robotics and distributor of OnRobot. "Because it is so flexible, we were able to adapt it individually to the application. The concept of the one-stop shop allows us to find the right solution for every application".

Increased efficiency, product quality and turnover

The fingertips of the RG6 can now be replaced within minutes. All the employees have to do is loosen a few screws, attach the new fingertips and screw them back in again. This enables them to quickly adjust the gripper to changing workpieces whenever the varied manufacturing process requires it. If new products are added, the employees develop suitable fingertips together with Olmia Robotics. This flexibility is reflected in time savings and better delivery reliability. "With the collaborative application of OnRobot, we have found a solution that exactly meets our requirements," says Zentveld.

The collaborative application has also doubled the productivity of the CNC machine within a short time, while the failure rate has been halved. Even without human intervention, the application runs smoothly and can be used overnight. The constant operation of the machine has even more advantages: "Production is now much smoother - you can tell this from the product quality, which is much more consistent than before," comments Zentveld.

Application takes the strain off employees

The employees also reacted positively to the helping hand on the CNC machine. "For us, the automation solution from OnRobot is a great relief," says Josine de Groot, employee at Donk Industries. "We can give up a monotonous task and thus have more time to take care of more demanding things - such as quality control or technical drawings.“

Donk Industries does not lose any jobs by automating CNC assembly. In fact, valuable working time now flows into activities that previously could only be performed inadequately. Thus, the application helps to counteract the shortage of skilled workers.

Further automation planned

In the future Donk Industries wants to focus even more on automation. "The entire project has shown us that automation is a real enrichment for our company and our employees," Zentveld sums up. "In addition, we can now produce much more efficiently.” Zentveld and his team are planning to automate further CNC machines with OnRobot solutions in order to relieve the strain on employees. In this way, the traditional company remains fit for the future - and ensures that it will be able to support its customers as a competent partner for at least another eighty years.