Deep Vision System for Logistics

3D cameras and advanced algorithms depalletize boxes

Jun 12, 2024 — Logistics, warehouses and e-commerce are incredibly important and continuously growing markets; since the volumes increase year over year, their need for automation is bigger than ever.Traditional automation perfectly fits with high volumes but it is often hindered by the kind of heterogeneity and product diversity which characterises the above mentioned markets and needs.

Bringing together Artificial Intelligence (AI) techniques and robots is necessary to simultaneously deal with high volumes and high product heterogeneity.

Comau has thus combined its historical experience in automation with the deep knowledge of vision systems in order to design and develop a deep neural network able to identify any kind of box without constraints in terms of lighting conditions, dimensions, colours, texture and even title position with respect to the ground, in fact, the Comau solution if effectively able to pick angled boxes thanks to the 6 degrees of freedom offered by its robot family.

Technological Approach

The newest solution in Comau’s MI.RA family (Machine Inspection Recognition Archetypes) utilises 3D cameras and advanced algorithms to reliably detect and depalletize boxes and containers in a fast, accurate and cost-effective manner.

From standard boxes with well-known sizes to single SKUs with uncertain positions, MI.RA/Depalletizer can also manage mixed-type SKUs with unknown sizes, positions and palletizing geometries. To achieve such flexibility, the intelligent, all-in-one solution is designed to easily recognize and react to different packages taking their contents and final location into account.

With its inherently intelligent advanced robotics and powerful vision systems, MI.RA/Depalletizer ensures absolute flexibility in terms of packaging types, pallet logistics, robotic technologies and the grasping strategy. Furthermore, MI.RA/Depalletizer can significantly reduce commissioning time by up to 70% in both single-type and mixed-type SKUs .

From the picking of products to the packs that will contain them, MI.RA/Depalletizer automates the entire depalletization process, optimising operational logistics as well as your bottom line.

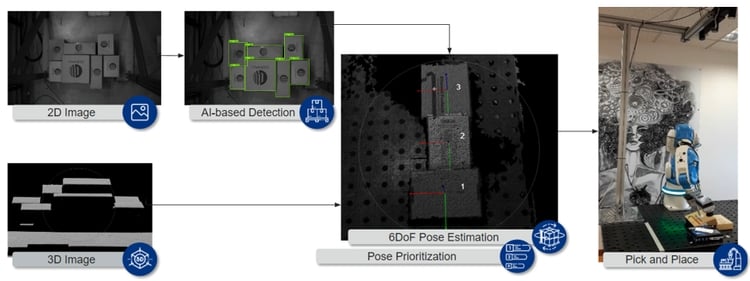

The vision system algorithm has been developed aiming at hardware agnosticism, which allows it to be compatible with all the 3D cameras. As shown in Figure 2, which summarises the technical pipeline, the deep neural network has been trained on grayscale images for different boxes, colours and textures. The bounding boxes provided by the AI engine are then used to optimise the postprocessing on the point cloud, which returns a 6 degrees of freedom pose estimation as well as the prioritisation and the accuracy of the picking. The robot picking can then proceed straightforwardly.

As all the other Comau vision system products, Mi.Ra Depal is offered as a standalone vision system as well as a turn-key solution: integrating a wide range of different robots and design and engineering layout and solutions in order to adapt and solve the specific customers’ needs.

Customer benefits:

- Fully automates single-SKU and mixed-SKU depalletizing regardless of the box positions

- Hardware agnostic and robot agnostic: choose the best configuration for your application

- Advanced flexibility extends to pallet size and heights of over 2m tall

- High-speed solution can reach cycle-times of up to 800 SKUs/hour