No More Walking 20 km!

How Duka Uses AGVs in Manufacturing

Feb 10, 2026 — A necessary part of any manufacturing process is moving components from A to B. One of the leading shower enclosure manufacturers in Europe shifted this work from employees to a fleet of ANT driven AGVs. While previously employees would walk 20 km every day to bring components to their workstations, this labor is now completed automatically, freeing up employees for more value-added (and interesting) tasks.The compact AGVs are less physically intimating © BlueBotics

“The idea to invest in automation arose with the construction of our new headquarters,” says Thomas Gruber, IT Manager at Duka. “Every process at Duka was re-analyzed and re-thought. The biggest reason to invest in automation was to automate non-value-adding activities as much as possible. The goal: to modernize and simplify our intralogistics.”

Project Details: Duka Shower Enclosures

Location: Duka, Bressanone, Italy

Application: Internal transportation of parts from automated warehouse to pre-assembly and assembly cells

AGVs: 11xEsatroll Dukino AGVs

Software: ANT navigation (vehicles), ANT server (fleet manager, integrated with in-house ERP and WMS)

Managing Intralogistics with AGVs

“Before the introduction of AGVs in our production, our employees walked 20 km a day,” says Yuri Scalzo, Process Manager at Duka. “For this reason, we decided to introduce AGVs into our production process to make their work more interesting and to add more value.”

The fleet of 11 AGVs are assigned three main tasks.

Firstly, the fleet transports material from Duka’s central warehouse to various bays in the component assembly department. Once component assembly is completed, the material is brought back from the assembly department to the central warehouse.

The second and third tasks involve moving material to the production line. The AGVs move material from a buffer zone which connects two production floors and previously assembled materials from the central warehouse to the start of the production line. From there, operators pick material for each order.

While previously employees had used pallet jacks to manage intralogistics, the Duka team decided to go in a different direction, choosing a smaller underride AGV over a forked AGV. The compact form factor fits neatly in the small bays, and the more ‘human’ scale of the robots make them less physically intimidating. Scalzo explains: “We decided to use a type of slightly smaller robot (Esatroll Dukino) to manage the connection between humans and machines. Thanks to the compact size of our production area and the dimensions of the boxes we used in our automated warehouse, we managed to handle everything perfectly with these robot specifications.”

The Right Box to the Right Place at the Right Time

“Every year, when we have visitors at the company, they are truly impressed by the performance of these AGVs,” says Scalzo. “They find it hard to understand how everything works so well, especially the precision with which they enter the various bays, given that they have very few centimeters of tolerance.”

The robotic fleet operates using ANT natural feature navigation. Using the vehicle’s built-in safety laser, they orientate themselves from fixed points (features) within the production environment.

Scalzo continues: “Thanks to this we are very flexible, because we do not have magnetic strips on the floor or similar structures. The AGVs can move without causing any disturbance and with extreme precision.We can change the direction of an AGV at our discretion, whenever and however we want.”

The entire fleet is managed with a single installation of ANT server. The Duka team made the decision to bring the fleet management in-house for maximum flexibility. “We decided to undergo advanced training on the ANT software to be more flexible during our working hours and to provide live service, without having to wait and without needing to communicate with suppliers or other external parties,” says Scalzo. “For example, we can change the different paths of the AGVs and make modifications to a pick-up or drop-off point for each individual box, making us independent in all our decisions within the company.”

“The software is very easy to use and thanks to constant updates from BlueBotics we can also develop new ideas within the company without needing to interface with other people, other companies, or BlueBotics. ANT server, in our case, is fully integrated into our other production systems. For example, by pressing a button on our ERP, this communicates with our WMS, which communicates with ANT server, and thanks to this system integration it can deliver the right box to the right place at the right time.

Modernized and Simplified Intralogistics

The Duka team have achieved their goal of modernized and simplified intralogistics. By automating repetitive tasks, their workforce can focus on value-adding tasks.

Gruber confirms: “Before using the AGVs, every employee had to search for their components themselves and bring them to the workstation by hand. This preparation time was therefore very long. We can now save this time because the AGVs provide the components to the workstation.”

Besides relieving workers of unnecessary labor and simplifying intralogistics, the process of automating brought other benefits. Examining every process pressed the team to improve their internal data: “Another advantage of automation was that we had to prepare all the master data and bill of materials perfectly and cleanly. Because without clean data, there is no automation,” concludes Gruber.

Robots in the Bakery

"Bakisto" relieves employees and reduces food waste

Dec 15, 2025 — “Bakisto” could relieve supermarket and discount store employees from repetitive tasks, introduce higher levels of reliability into the baking process and reduce food waste.The robot manufacturer FANUC, baking oven manufacturer WIESHEU and retail specialist Wanzl have jointly developed the automatic "Bakisto" system. A prototype was presented at the EuroShop 2023 trade show in Duesseldorf. Soon, “Bakisto” could relieve supermarket and discount store employees from repetitive tasks, introduce higher levels of reliability into the baking process and reduce food waste. The system involves a robot performing important work steps, such as loading the baking tray, inserting and removing the tray from the oven, and stocking the displays.

"Bakisto" consists of three interconnected systems: a FANUC collaborative robot (cobot); Wanzl's smart baked goods presenter BakeOff i with Artificial Intelligence (AI) and Dibas blue2 network-enabled baking oven; and the WIESHEU TrayMotion automatic loading and unloading system. Based on historical data and current stock, the AI in BakeOff i estimates the daily quantity requirements for baked goods and when peak baking should take place in order to meet demand.

Motion System provides flexibility

With this information entered into the system, the cobot fetches the baking trays loaded with frozen baked goods from the refrigeration unit and pushes them into the transport trolley, which runs on rails in front of the preheated oven. The TrayMotion loading system pulls in the loaded trays so that the baking process can begin.

After baking, the system pushes the baking trays back into the transport trolley, which moves to the side, allowing the baked goods to cool down while also making space for subsequent production. The cobot then fills the predefined compartments of the BakeOff i with the finished and cooled baked goods. Feeding new data into the AI, continuously optimises the process.

The increasing shortage of skilled workers is driving interest in robots outside of the manufacturing industry. Robots can bring noticeable relief in sectors like retail or the trades, where the convention is to carry out work steps manually, up to now.

Introducing robots into the bakery environment would benefit employees in many ways, including through more attractive working hours. In the case of "Bakisto", a collaborative robot (cobot) starts baking on its own early in the morning if programmed accordingly, allowing employees to sleep longer.

Artificial intelligence determines production volume

The robot system also helps to combat food waste as “Bakisto” uses artificial intelligence to calculate how many rolls, croissants and pastries are likely to be in demand during the course of the day, before preparing the baked goods and taking them out of the oven at the right time.

Sales quantities are highly dependent on factors such as the weather, school holidays and local events. The system takes this information into account and bakes appropriate quantities, which means less stress for employees because they don't constantly need to keep an eye on the displays and ovens. Instead, they can concentrate on other tasks.

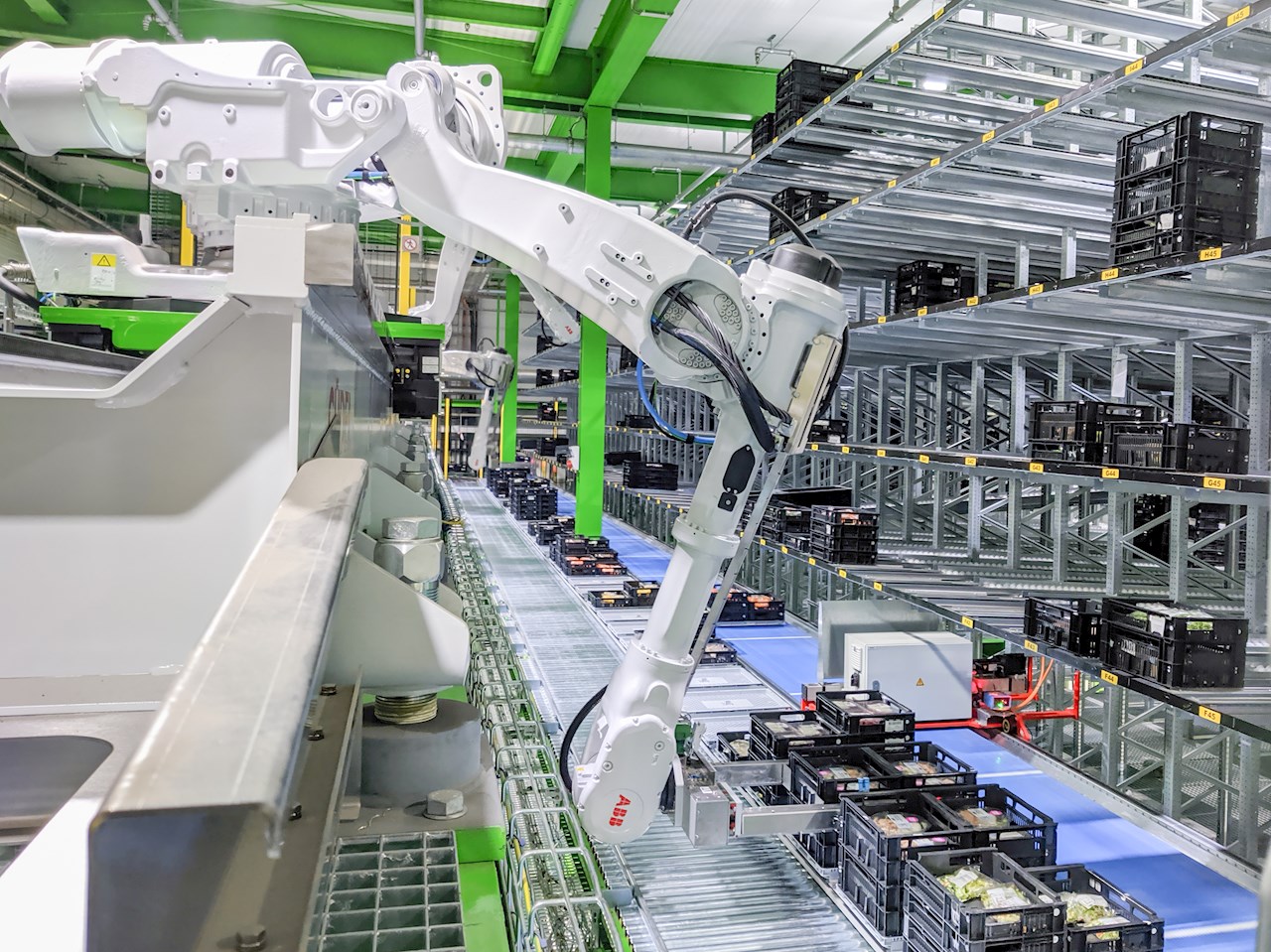

One of Europe’s largest online grocers automates order picking in Prague fulfillment center

Dec 11, 2025 — Rohlik, the leading online grocer in the Czech Republic and one of the largest online grocers in Europe, has automated order picking in its Prague fulfillment center using Brightpick.

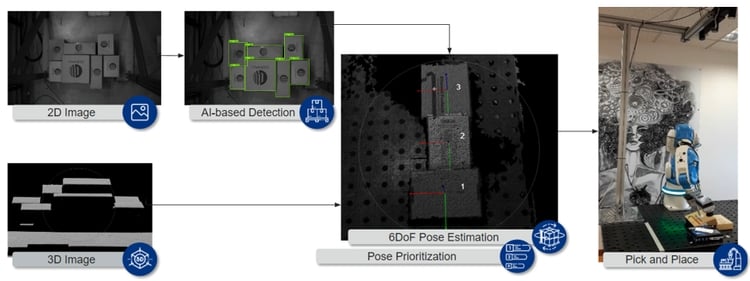

Brightpick uses autonomous mobile robots to retrieve totes from storage and bring them to robotic picking stations. Image credit: Photoneo

Rohlik’s Horní Počernice fulfillment center in Prague ships out approximately 7,000 orders per day and holds 18,000 SKUs across ambient, chilled and frozen temperature zones. The ambient zone consists of a three-storey mezzanine structure.

Brightpick automated the first floor of the existing mezzanine structure in the ambient zone. Brightpick’s Goods-to-Robot solution picks and consolidates orders using autonomous mobile robots (AMRs) and robotic picking arms.

Brightpick AMRs autonomously navigate using LiDAR sensors and are designed to safely operate around humans. The robotic picking arms are powered by Photoneo 3D scanners and use proprietary AI algorithms, which have been trained on more than 250 millions picks to date. The entire robotic fleet and fulfillment process is orchestrated and optimized by Brightpick Intuition software.

All 2,500 SKUs in the automation area were robotically pickable, which enabled Rohlik to cut picking labor to zero and reduce picking errors. The solution was designed to achieve 600 picks per hour.

In addition, the Brightpick solution also automated inventory replenishment. AMRs transport totes from decanting stations and dynamically slot them into the most optimal storage location. Totes that contain faster-moving merchandise are stored closer to the picking stations to reduce picking times.

Brightpick’s solution required minimal changes to the existing layout – Rohlik’s existing 2-meter-tall shelving, which was previously used for manual picking, was kept fully in place. As a result, Rohlik could leverage its existing footprint, avoid additional capital investment, and install Brightpick in weeks without any interruption to service. Despite this challenging brownfield environment, Brightpick met the strict SLAs necessary for Rohlik to deliver customer orders in 60 minutes or less.

“Before installing Brightpick, our picking process was entirely manual. Brightpick enabled us to install end-to-end automation without making any major changes to our existing warehouse processes. Their solution enabled us to practically eliminate our picking labor and reduce picking costs.” said Aleš Malucha, Rohlik Group’s Chief Engineering Officer.

Subsequent phases could see Brightpick automate the second and third floor of the ambient mezzanine and the chilled picking zone.

In addition to automating ambient order picking, Brightpick has also automated part of Rohlik’s dispatch process in the same fulfillment center.

Improving operations and product availability at stores globally

PAL Robotics' StockBot at Decathlon stores

Nov 24, 2025 — Global sports retailer Decathlon was looking for solutions to be able to assist teammates in their daily tasks in stores, which would also allow them to spend more time helping customers. In addition, they wanted to be able to provide more accurate data on inventory, as well as save time that was taken to do inventory taking manually, impacting on in-store efficiency and productivity.

Decathlon StockBot robot by PAL Robotics at Singapore store (image: PAL Robotics)

Decathlon is a family-owned company, founded in 1976 in France, and inspired by the belief that sports and the outdoors should be accessible to everyone. They focus on ever-evolving and high-performance design, the best quality at the lowest possible price, and expert advice that customers can access in-store or online.

The company manages the research, design, production, logistics, and distribution of its products including sports equipment and clothing in-house; as well as partnering with global suppliers.

The company aims for an optimised supply chain and minimal retail footprint and usually favours large superstores averaging 4,000 m2 in size and reaching 9,000 m2 in larger stores. Optimising the supply chain also contributes to sustainability - by being able to reduce logistics efforts, lessening the need for unnecessary movement of stock between sales points, and stock optimisation by cutting down on overstocking of products.

In retail stores such as Decathlon, radio-frequency identification (RFID) is often used to provide accurate data on a store’s inventory or stock, as the technology transmits data from RFID tags on products to readers. Complete RFID solutions are made up of different components that work together: tags, readers, and antennae, as well as supporting software.

Automating the RFID processes at Decathlon stores, by introducing AMR robots by PAL Robotics as the RFID solution would be the challenge here. The AMRs would need to work effectively in a dynamic environment, with moving obstacles, including people, in stores during opening hours.

With the deployment of RFID robots, Decathlon wanted to take the opportunity to try to automate the counting of stock - since stock counting manually is a less repeatable process, prone to errors, and dependent on the performance of team members. They also wanted to help the team be more available to advise customers and not work on non-added value tasks such as counting stock.

PAL Robotics’ StockBot solution is an Autonomous Mobile Robot (AMR) designed for inventory tracking and data collection in retail. StockBot is equipped with RFID antennas and readers so that the robot is able to move autonomously in stores to detect the tags that retailers use on products, then create the full inventory plus the location of the items in the store, which is not possible when stock taking manually with hand-held devices. StockBot is easily deployed within stores as it does not require any layout modifications and is integrated with existing software systems. The solution is typically set up in each store in one day.

At Decathlon stores, RFID robots perform SLAM – simultaneous localization of their own location and mapping of any area. SLAM includes Spatial AI, the spatial reasoning that allows robots to operate in general ways where they are, and helps them to understand their environment, such as the store or warehouse, better. This includes environment understanding by sensor fusion (laser + 3D cameras), analysis of obstacles and finding the optimal way to avoid them, as well as automatic generation of new maps of local regions where important changes are detected.

Inventory management assisted by StockBot allows the creation of demand forecasts based on data, and the AI used learns more and it constantly improves its forecasts to become more efficient. In this case, the robot integrates with the Inventory Management software used by Decathlon.

The AMR StockBot was customised in order to be introduced at Decathlon stores globally. The StockBot solution was initially deployed in Decathlon, Singapore. Following the success of this trial, the solution was chosen for roll-out in stores across multiple countries worldwide, including France, The Netherlands, Spain, Portugal, Poland, Ireland, Italy, Taiwan, and Australia.

StockBot is programmed to automatically read all of the inventory each day (daily inventories) so that the next day the teammates have the stock counted with data available on their smartphones, and are able to check for any discrepancies. In Decathlon stores with the solution, StockBot is considered a new teammate that assists workers and improves the capability to have stock available, as this is equal to huge benefits for the customer.

Customer benefits

Key benefits for Decathlon stores have been to conduct more frequent inventories in order to gain better visibility of stock, and of course, to optimise operations, resources, and costs.

The implementation of StockBot allows the company to increase the frequency of inventories as the robot is in operation continuously. The implementation at the store in Singapore enabled the team to finish inventories in a space of 5000 m2 within 5 hours, compared to having 80 teammates working a 12 hour shift. Janice Morin, Sports Leader for Trail Running in Decathlon Singapore explained, “before we had StockBot stock-taking work was very laborious, it was very manual and we allocated a lot of time to do our inventory. Now when we finish all the inventory we can allocate our time to do other things.”

As well as improving in-store operations, the retailer also aimed for better product availability rates. Mathieu Blanchard, Technical Director of Decathlon South East Asia said, “for any retailer, ensuring that customers are visiting your store and will find the products they are looking for is crucial.”

In addition, all the time and costs that employees spent on taking inventories can be spent on other more value-added tasks such as direct customer service, which, as a result, leads to a better and more complete customer experience.

Making decisions with the data provided by automation with a robotic tool means improving the efficient management of products, reducing costs, and reducing response time to product demand. The StockBot solution also helps Decathlon stores to determine easily and efficiently, a comparison of item sales depending on product placement in-store.

Additionally, the use of StockBot has helped Decathlon stores to maintain the success of facilities they offer such as ‘click and collect’ services, by identifying the products in the store to help prevent frustrastion for customers over stock discrepancies or outdated stock information, and reducing overstocking in stores where the demand is lower in comparison with other locations.

AI and digitalization have contributed to the success of the solution at Decathlon through a number of features:

- Robot navigation (wheel odometry) & environment perception (cameras RGB-D)

- Traceability tags on products

- Virtual shielding (RFID parameters) in-store

- Tags positioning (triangulation) to track product location

The future

PAL Robotics and Decathlon are discussing potential additional collaborations - not only with inventory tracking and data collection through StockBot, but also RFID use cases in intralogistics.

PAL Robotics continues to respond to requests for the roll-out of StockBot in Decathlon stores in additional countries in Asia and Europe, as well as to increase the number of robots in stores where StockBot is already deployed. Thanks to the partnership with Decathlon, PAL Robotics also is able to work on developing further capabilities on StockBot.

Implementing Intelligent Robotics in Geriatric Rehabilitation

Singapore United Medicare Centre

Aug 07, 2025 — With the rapid increase of the global ageing population, prone to diseases and injuries, the intervention of rehabilitation robots in the clinical environment can assist by addressing the global insufficiency of clinical therapists.

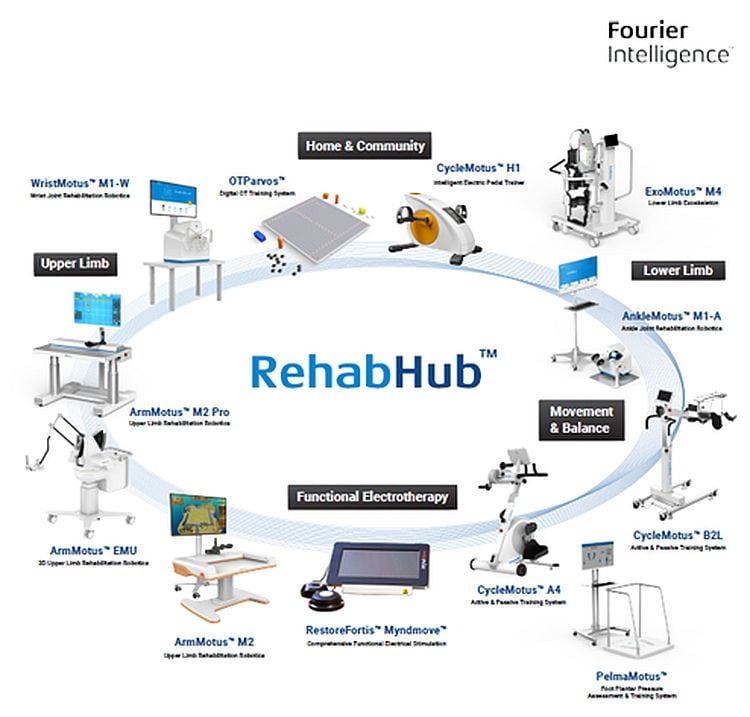

The RehabHub™ aims to create a diversified and inclusive ecosystem, enabling greater patient recovery through robotics. image copyright: Fourier Intelligence

Introducation

Globally, the WHO has estimated that over 1 billion people are affected by disabilities that impact their mobility and independence. In addition, by the year 2050, the global population of individuals aged 60 years and above is projected to reach 2.1 billion. Seeing the need to combat this rising need, the Singapore United Medicare Centre (UMC), Toa Payoh, a purpose-built nursing home opened in 2003 by then Minister for Health, Mr Khaw Boon Wan, embarked on integrating intelligent robotics and AI into its rehabilitation services. This initiative aimed to address the growing demand for quality nursing care outlined by the Ministry of Health (MOH), marking a significant step towards innovative elderly care. With the rapid increase of the global ageing population, prone to diseases and injuries, the intervention of rehabilitation robots in the clinical environment can assist by addressing the global insufficiency of clinical therapists.

Initial Problem/Task

Customer Profile:

- Industry: Healthcare (Geriatric Rehabilitation)

- Company Size: Medium-sized Nursing Home with Rehabilitation Centre

- Country: Singapore

- Challenge: Providing continuous, personalised, and intensive rehabilitation for an increasing number of elderly patients, many of whom suffered from stroke, musculoskeletal conditions, or cognitive impairments, was becoming increasingly challenging. The centre aimed to improve rehabilitation outcomes, enhance patient engagement, and alleviate the physical strain on therapists and caregivers.

Solution

What was installed:

Machine/Layout: The "RehabHub™", a suite of intelligent robotics explicitly designed for geriatric and neurorehabilitation, was introduced. It consists of upper, lower, balance and movement solutions from Fourier Rehab’s inventory of robotic devices. These solutions allow therapists to utilise advanced sensors, AI algorithms for personalised therapy, and an engaging interface for individual and group therapy sessions. In addition, the system supports ongoing research and development in rehabilitative technology. With its ability to collect and analyse large volumes of data, the RehabHub™ provides valuable insights that can be used to refine existing therapies and develop new ones.

Why This Solution: The RehabHub™ was chosen for its ability to adapt exercises in real-time based on patient performance, provide motivational feedback, and support a wide range of rehabilitation activities. It is a versatile tool that allows healthcare providers to cater to different patient needs, allowing for effective and comprehensive rehabilitative care and making it a one-stop solution for patients. Catering for upper, lower, movement and balance, patients who require attention in different areas can entirely focus on their recovery journey without being required to travel to multiple locations to receive various treatments. Whether a patient is recovering from a neurological event, such as a stroke, or managing age-related physical decline, it provides a unified platform that accommodates an expansive array of therapeutic exercises.

Implementation Timeline: The solution was implemented within three months, including setup, clinical staff training, and full integration into the daily rehabilitation programs.

Evaluation

Benefits:

Enhanced Rehabilitation Outcomes: The introduction of the RehabHub™ has marked a transformative shift in the landscape of rehabilitative care, particularly in enhancing patient outcomes across several crucial domains: mobility, balance, and cognitive functions. The improvements observed in these areas can be attributed mainly to the system's AI-driven, personalised, and adaptive approach to therapy, providing therapists with crucial information on the patient's mobility and range of motion, which allows for highly adaptable rehab protocols and treatments for different needs.

Increased Patient Engagement: The devices within the hub significantly boosted patient motivation and satisfaction, making the rehabilitation process more appealing. Implementing gamified therapy allows patients to be highly engaged throughout their sessions. As traditional therapy methods involve patients doing repetitive and non-engaging tasks, gamified therapy, incorporated into each device within the hub, gives patients motivation and satisfaction during and after individual sessions. The system helps sustain patient interest and enthusiasm throughout recovery by transforming rehabilitation exercises into engaging challenges. This increased engagement is crucial as it makes patients look forward to their therapy sessions and deeply involves them in the activities. As a result, they are more likely to adhere to their therapy regimen and less likely to abandon it.

Reduced Physical Strain on Therapists and Caregivers: By automating many of the repetitive and labour-intensive tasks associated with rehabilitation, RehabHub™ has revolutionised the role of healthcare professionals, enabling them to focus on more complex and nuanced aspects of patient care. These tasks, such as assisting patients with exercises or manually recording patient movements, can lead to physical strain and fatigue among healthcare workers. With the burden of repetitive tasks lifted, therapists and caregivers can redirect their energies towards more complex elements of rehabilitation care. This includes developing personalised care plans, monitoring patient progress with greater detail, and engaging in direct patient interaction focusing on psychological and emotional support. The ability to concentrate on these areas enhances the quality of care provided and allows for a more holistic approach to patient rehabilitation.

Contribution of AI and Digitalisation:

AI Algorithms: AI algorithms serve as the backbone of the RehabHub™, playing an indispensable role in revolutionising rehabilitation care. These advanced algorithms are essential to deeply analysing patient data, allowing for customised therapy sessions tailored to each patient's needs and response patterns. This capability of making real-time adjustments based on patient responses enhances the efficacy of treatments and significantly improves patient outcomes. Designed to process a vast array of data points collected during therapy sessions, including movement precision and patient feedback, the AI can analyse these data and identify patterns and nuances in a patient's progress and struggles, which might be overlooked in a less sophisticated setup.

Digitalisation: The digitalisation features of the hub play a pivotal role in modernising rehabilitation practices. A vital aspect of this technology is its ability to facilitate seamless patient data integration with a centre’s Electronic Health Records (EHR). Through InfinityNet™, a cloud-based system that links all devices within the RehabHub™, this capability promotes a holistic approach to patient care and significantly enhances the rehabilitation process's efficiency and effectiveness. Automating the data entry process reduces the likelihood of manual errors and increases data management efficiency in rehabilitation settings. Minimising the need for handwritten notes and manual record-keeping saves time and reduces the potential for errors in the transcription and handling of physical documents. This leads to a more reliable and streamlined process, allowing therapists to spend more time with patients rather than on administrative tasks.

Conclusion

The successful integration of intelligent robotics and AI at the Singapore United Medicare Centre's rehabilitation facility demonstrates the transformative potential of these technologies in the geriatric healthcare sector. The RehabHub™ effectively addressed the specific challenges of geriatric care, offering a scalable, efficient, and engaging rehabilitation solution. This case study serves as a model for how innovative approaches can fulfil the needs of an ageing population, ensuring high-quality care and boosting the capabilities of healthcare providers in an increasingly digital world. Robot-assisted therapy has freed up the labour-intensive, repetitive work from the therapist, allowing them to focus on work that requires their professional knowledge, like therapy planning, prescription, and dexterous manual therapy that a robot cannot replicate. By doing that, a therapist's work efficiency has been maximised, offering more treatment sessions to the continually increasing patient populations.

Pioneering robotic Approach for Complex Assembly Process

Automated with AI

Aug 06, 2025 — As part of a development cooperation between Schaeffler and AICA, an AI-empowered automation solution utilizing Cobots has been industrialized, which, in addition to direct automation of a complex assembly process, also optimized the efficiency of automation engineering.

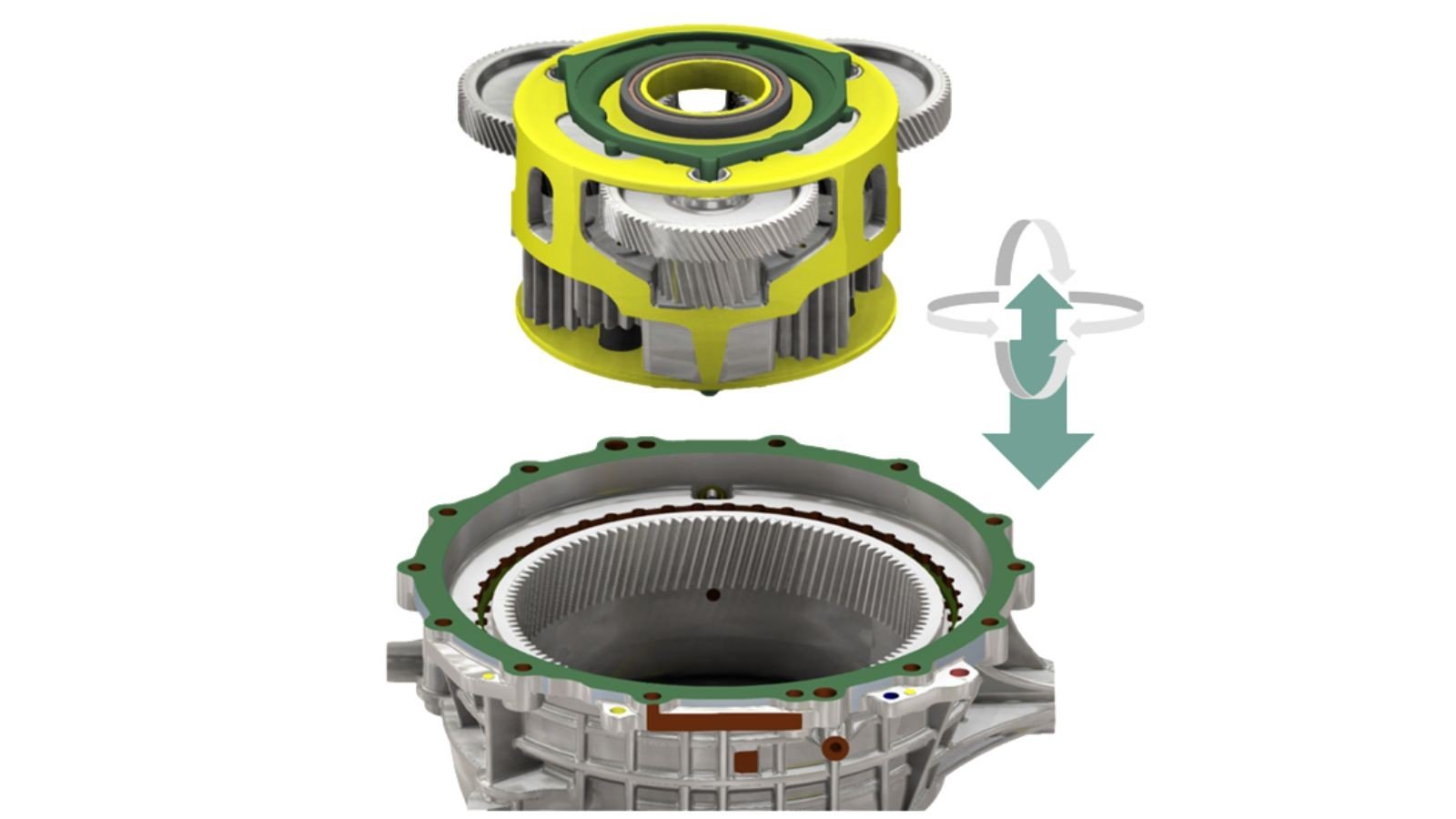

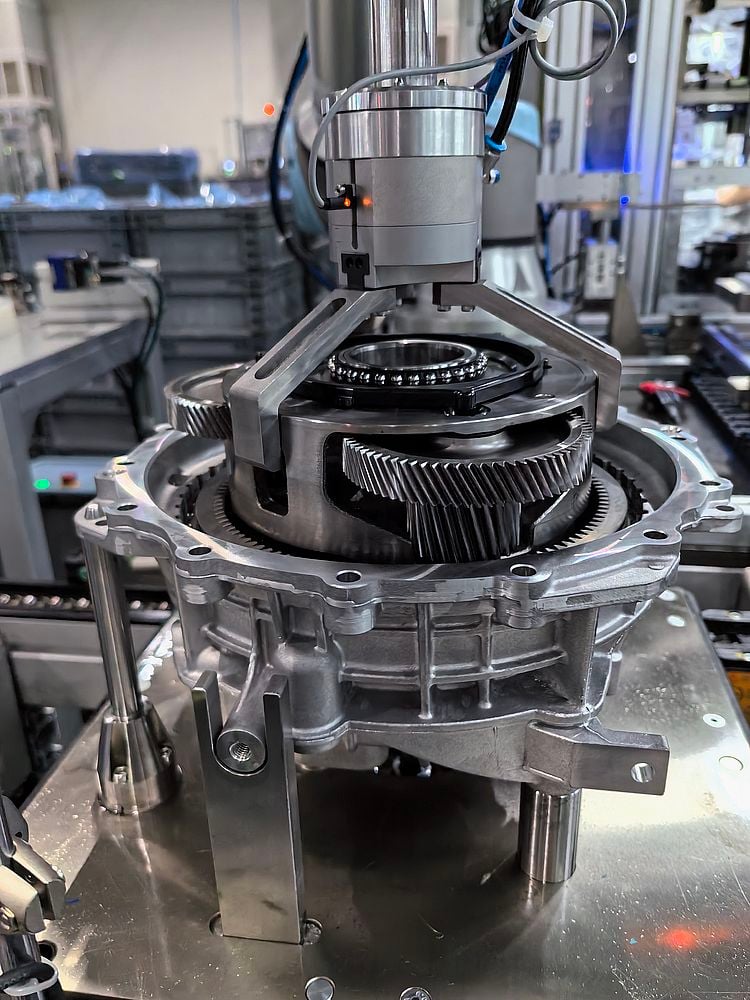

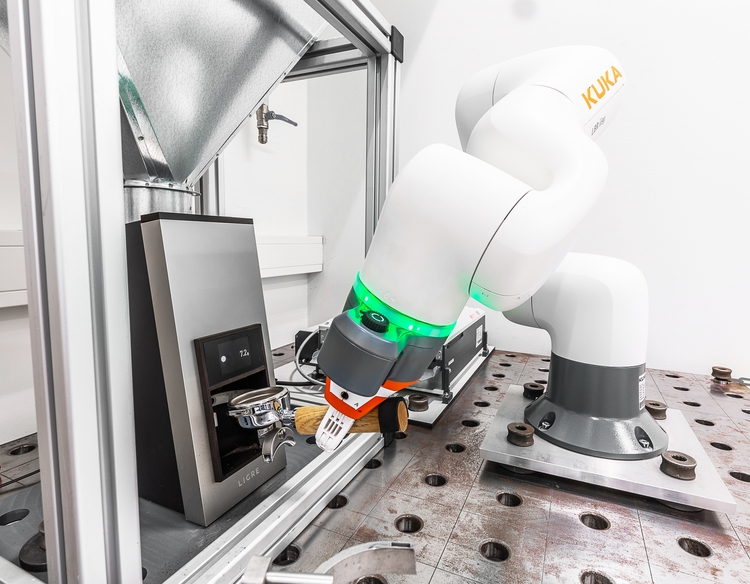

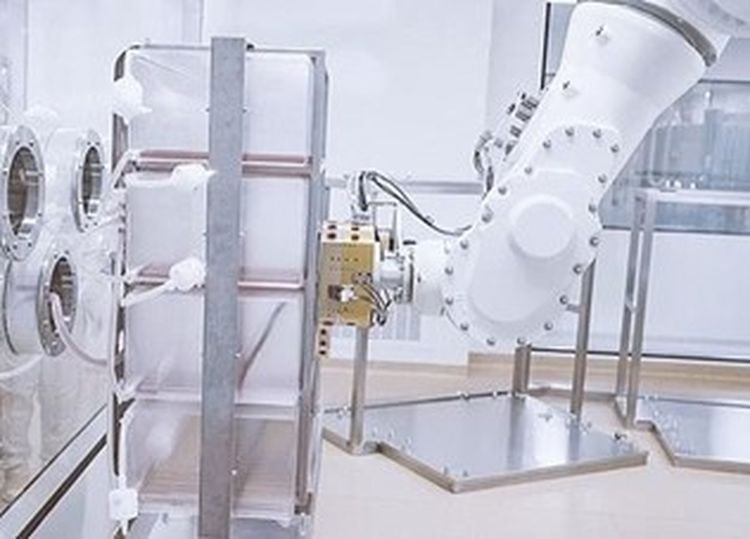

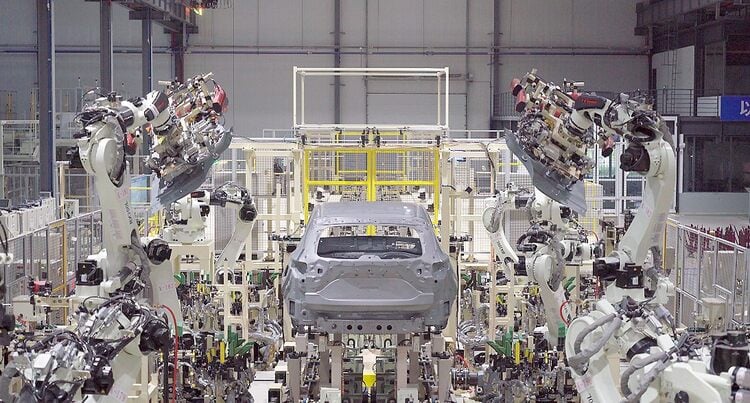

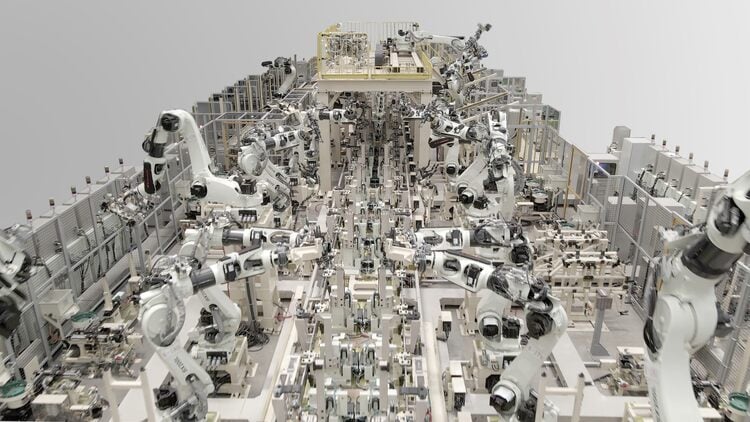

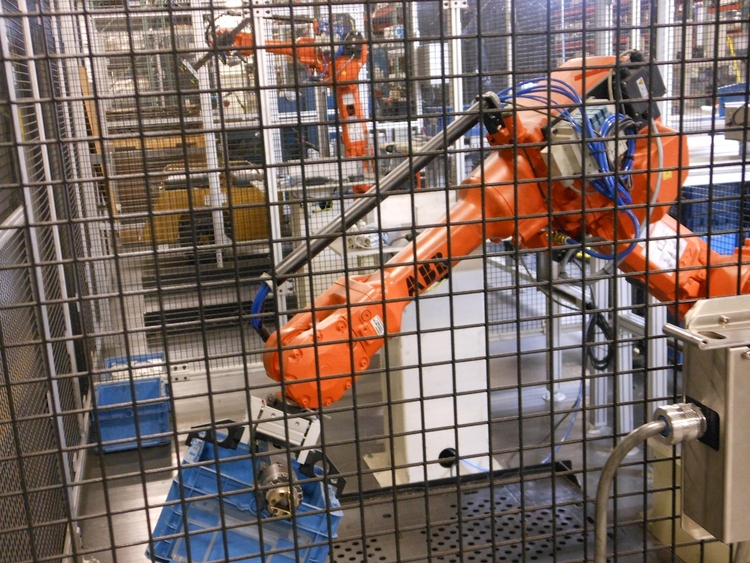

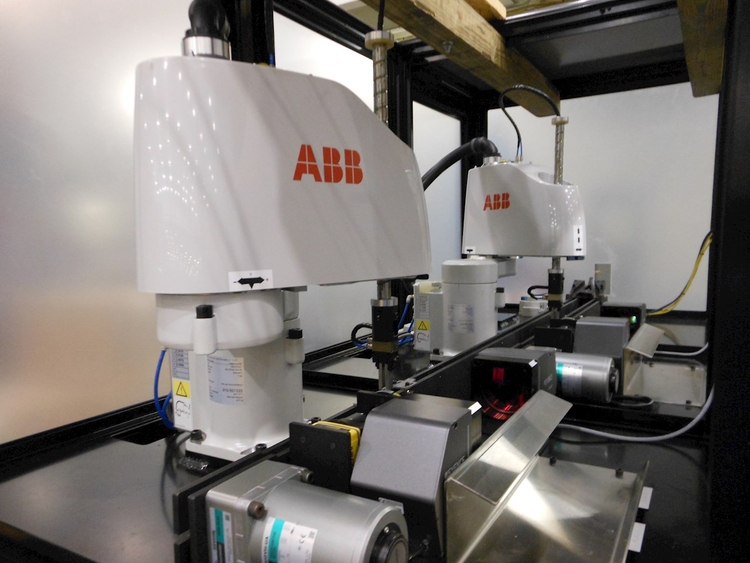

Complex gearbox assembly in the field of E-Mobility at Schaeffler - Image Copyright: Schaeffler Technologies

AICA Smart Assembly

Manufacturing companies are currently operating in a volatile market environment characterized by shorter product and technology life cycles and reinforced by a transformation towards more sustainability. As a result of the increasing scope of functionalities and degree of individualization, products as well as the associated productions are becoming more complex. Additionally, the progress of demographic change involving more and more regions globally brings further tension in manufacturing due to increasing lack of skilled employees.

New solutions in the field of complex assembly automation are necessary to accelerate the speed of adaption towards an efficient and flexible automation for cost-optimized production.

As part of a development cooperation between Schaeffler and AICA, an AI-empowered automation solution utilizing Cobots has been industrialized, which, in addition to direct automation of a complex assembly process, also optimized the efficiency of automation engineering. Within the first use case for the assembly automation of a planetary gear box in the field of E-Mobility the following key features and benefits arise.

Key Features & Benefits:

- Seamless integration with existing systems.x

- Real-time adaptation to changes in the production environment.

- Autonomous learning from force feedback.

- Improved productivity and efficiency.

- Enhanced precision and accuracy.

Gearbox Assembly Challenges

With the transformation towards system products in e-mobility and the increase of complex assembly tasks, Schaeffler strived to enhance the efficiency and accuracy of automated assembly processes to fulfill the requirements for precise assembly in a specified time. Up to now the robot automation for the assembly of gearboxes with conventional programming approaches represents a major challenge with high engineering costs and efforts in making production reliable. This is caused by the complex matching process of multiple, independently rotating and helically toothed planets with the helical ring gear of the housing. In addition, the tolerance range in weight, size and shape of the workpiece affects the process.

Ultimately, a new approach in robot programming should make it possible to overcome the challenges and implement new use cases as autonomously as possible with a minimum effort.

This is how the collaboration with AICA, a Swiss robotics company, was initiated. AICA itself is specialized in the development of software for the automation of complex assembly processes by using a reinforcement learning approach, a subfield of machine learning.

AICA's Cutting-Edge Solution

As part of the development cooperation between Schaeffler and AICA, AICA has tailored its state-of-the-art robot software to Schaeffler’s specific requirements and use cases. The software module ‘Smart Assembly’ uses real-time adaption, force feedback and autonomous learning capabilities (reinforcement learning) to optimize the assembly process. As a result, the robot independently and autonomously trains the optimum assembly parameters based on previously defined framework conditions and success criteria.

Significant benefits for Schaeffler achieved to date:

- #1 AI-empowered automation solution for assembly in series production use.

- More than 30% reduction of the development time.

- No dedicated expert knowledge required for robot programming.

- Hardware-agnostic solution.

International technology rollout and first successful industrialization in series production – Automotive E-axle assembly

As part of Schaeffler’s industrialization efforts to transfer the AI-empowered automation solution from AICA into series production, a use case in the field of e-mobility in the region Greater China was identified by the international production technology and innovation network. In cross-regional and cross-functional collaboration with the business unit and driven by the established ‘Advanced Production Technology’ function, the technology was enabled for use in series production.

The use case focuses on the automation of a helical planetary gearbox assembly, which is used as a subsystem in an e-axle drive system for electric vehicles. The challenge in the assembly process arises from the helical gearing of the three planets and the ring gear in the housing as well as the independently rotating planets (before assembly), which consequently have different initial positions themselves and in relation to each other.

Decisive steps in the systematically structured innovation process were the core technology development and adaption to Schaeffler-specific use cases in series production, followed by an international technology rollout. In cooperation with the business unit, proof of concept was performed in dedicated innovation centers with various designs and in addition the technology was finally qualified via a long-term test lasting for several months. This also included the detailed process and progress monitoring of the use-case with a monitoring software platform developed inhouse. In the end the solution was fully handed over to production in Q4/2023.

The advantages of the AICA solution were proven in various dimensions. On the one hand, the necessity of direct operators in the production line can be reduced due to assembly process automation. In addition, the engineering efforts to generate the planet carrier insertion trajectory can be minimized by the AICA solution through the reinforcement learning approach which runs autonomously compared to conventional robot programming. Furthermore, the necessary qualification level of the engineer to generate the use-case specific trajectories is much lower in contrast to conventional robot programming which leads to higher speed in terms of international technology roll-out und multiplying of use-cases.

In conclusion, the AICA solution already offers quantifiable potential after the first months of mass production implementation, and the scaling of the technology will continue in the region Greater China as well as in the rest of the Schaeffler world based on the positive results of this first use-case.

Successful Implementation & Positive Outcomes

The success of this partnership shows that many industrial challenges can be solved using adaptive force control and learning. AICA’s modular software blocks allowed the teams to iterate and refine robot applications at a fast pace.

As part of this collaboration, the two companies have additionally implemented the solution on collaborative and industrial robots incl. evaluations and optimizations. Schaeffler and AICA are currently working on further projects with the aim of improving complex process automation in the automotive and industrial business divisions. Furthermore, AICA is developing new products as part of its long-term strategy to enable its customers to benefit from machine learning and solve some of the world’s most challenging automation tasks.

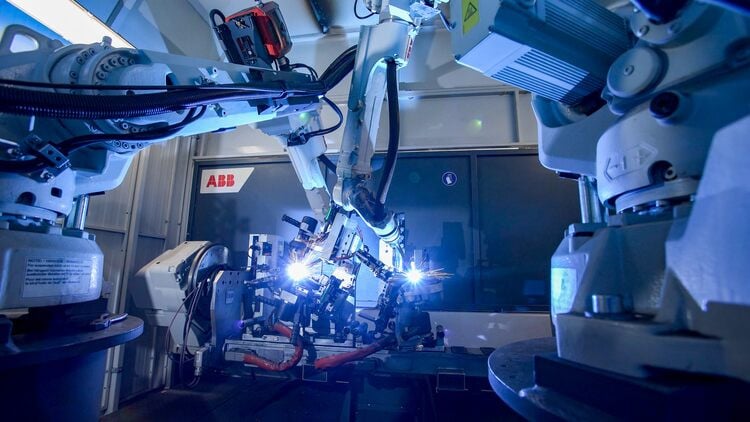

A Welder Wants a Robot

Relief wanted from difficult physical conditions

Aug 06, 2025 — At his request, a hand welding specialist working at OLEXA® is having a robotic system support him to perform certain repetitive complex tasks that are too difficult, too long, too hot, and too tiring for him to perform on his own.

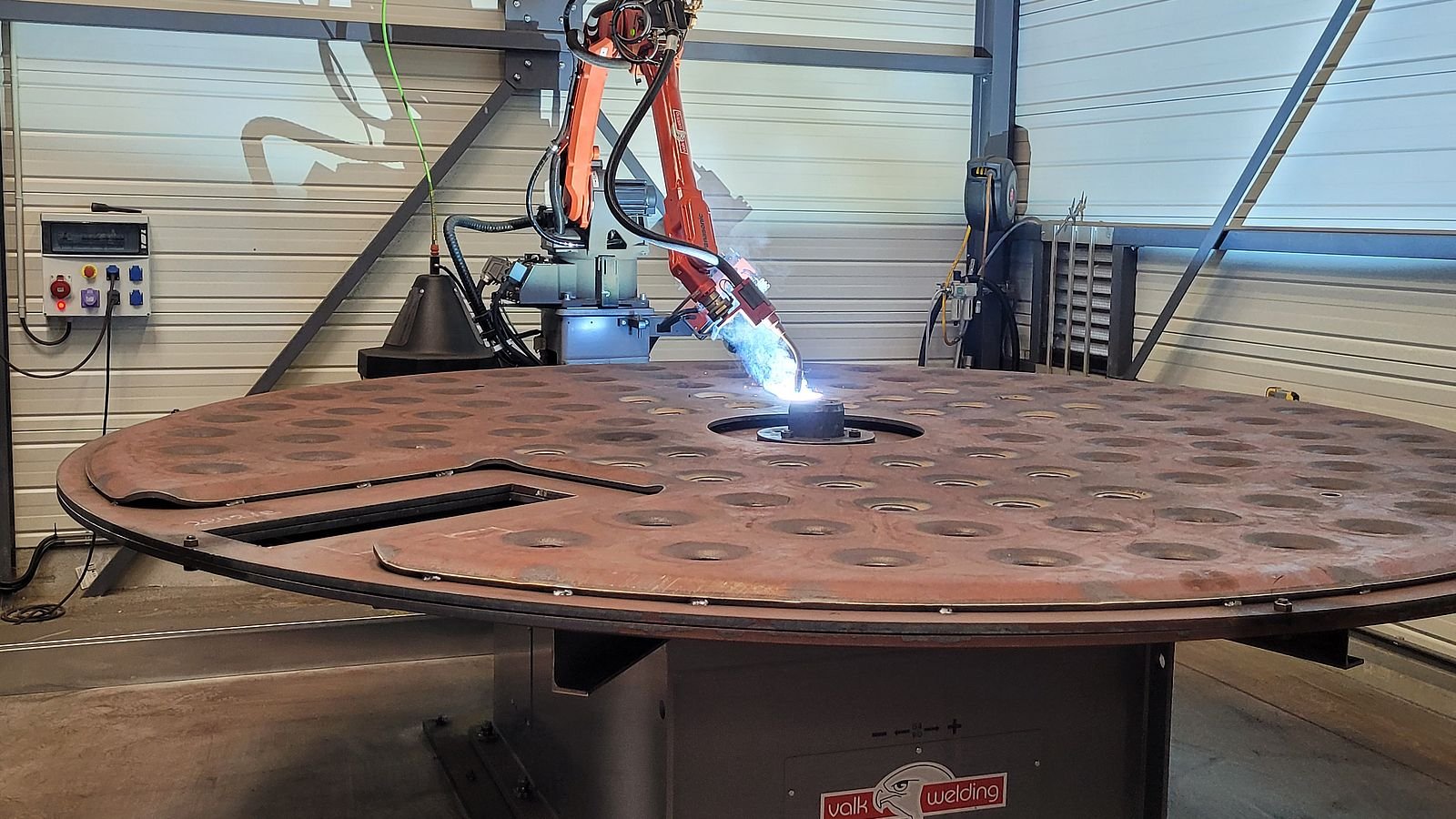

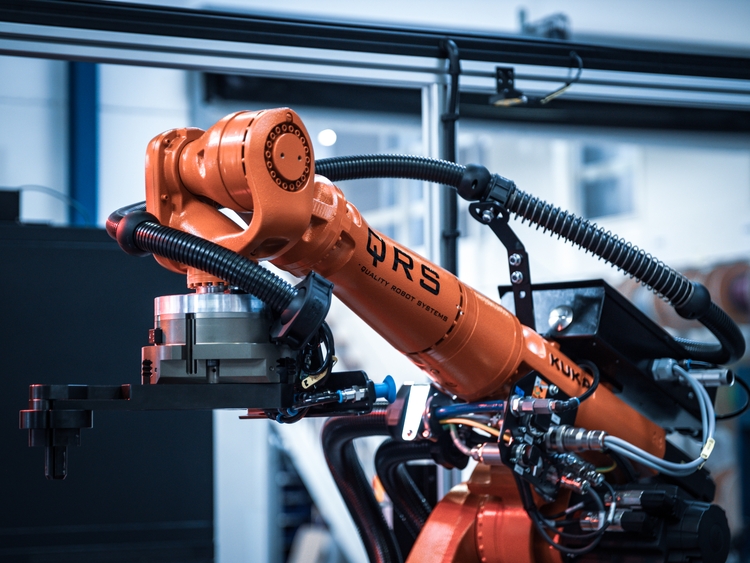

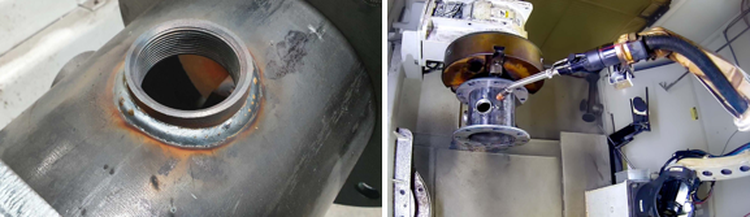

The cell completes each spiral weld in four and a half minutes - image copyright: Valk Welding

Founded in 1927, OLEXA® is a family-owned company specialising in continuous presses. It has more than 2,000 machines in operation in 50 countries in Europe, America, Asia, and Africa. OLEXA® (45 employees and €8 million in sales) designs and manufactures

oil and grease extraction systems and other special industrial applications at its 4,000-square-meter plant in Arras, France. In the boiler shop, an expert welder wanted to be replaced by a robot capable of performing long and heavy tasks.

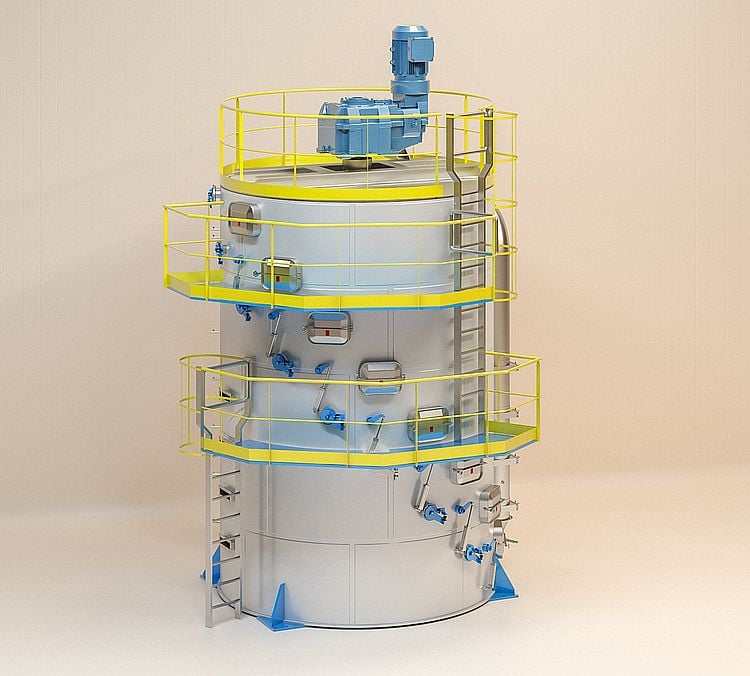

Briefly, oil extraction consists of processing oil seeds (rapeseed, sunflower, flax, soybean, cotton, hemp, peanuts, etc.) to extract the oil. OLEXA® provides turnkey units from seed receipt to storage of the finished products (oil and cake). The conditioner is an essential preparation before oilseed pressing and dehydrates the material to be processed.

The seeds are continuously spread and stirred on a tray and are heated and mixed at several coupled levels (from 3 to 12 trays per conditioner). Each circular tray contains a double skin in which dry steam circulates between 150° and 160°C under 6 to 8 bars. At each stage, a blade stirs the seeds.

The construction of these boilers is complex as each bin, 16 mm in diameter, is lined with a 12.5 mm thick plate. This is pressed at the perimeter and has several 70-mm-diameter conical lugs distributed under the heating surface. These 25-mm lugs serve as spacers between the two plates. Conditioners with a diameter of 3.7 m require about 110 spiral or "slag" plugs to connect the plates.

"Previously, our welder made each joint in five minutes, which required four days of work for a large bin in difficult physical conditions. The operator was overwhelmed by these repetitive tasks, with difficult to maintain ergonomics and difficult thermal conditions, despite the protection provided. At his request, this work is now done by a robotic installation." said Guillaume Wartel, production manager at OLEXA®.

Designed by Valk Welding, the welding robot installation combines a TL-1800WGH robot with an integrated 450A welding power source and a programmable rotary manipulator with a 5-ton capacity. The cell completes each spiral weld in four and a half minutes, or the 110 welds on a large plate in eight and a half hours with an effective duty cycle of 97%.

"At the beginning of the cycle, the quick touch system which runs through the welding wire, locates the position of each weld to the millimetre," he continued.

"We are known for the quality of our conditioners, and some have been in use for more than four decades. There is no doubt that this brand-new robotic installation will enable us to maintain this quality in the long term," concludes Guillaume Wartel.

AI advances Robotics Automation in the Home Appliance Sector

Mar 26, 2025 — In the early days of their advent, robots were only designed to undertake simple repetitive tasks. While the past decade has witnessed the utilization of Artificial Intelligence (AI) in industrial robotics, the ever-evolving AI technologies advanced robotics. Today, robots, paired with AI technologies, are undertaking demanding tasks that once could only be carried out by humans, such as assembly, dispensing, and quality control.

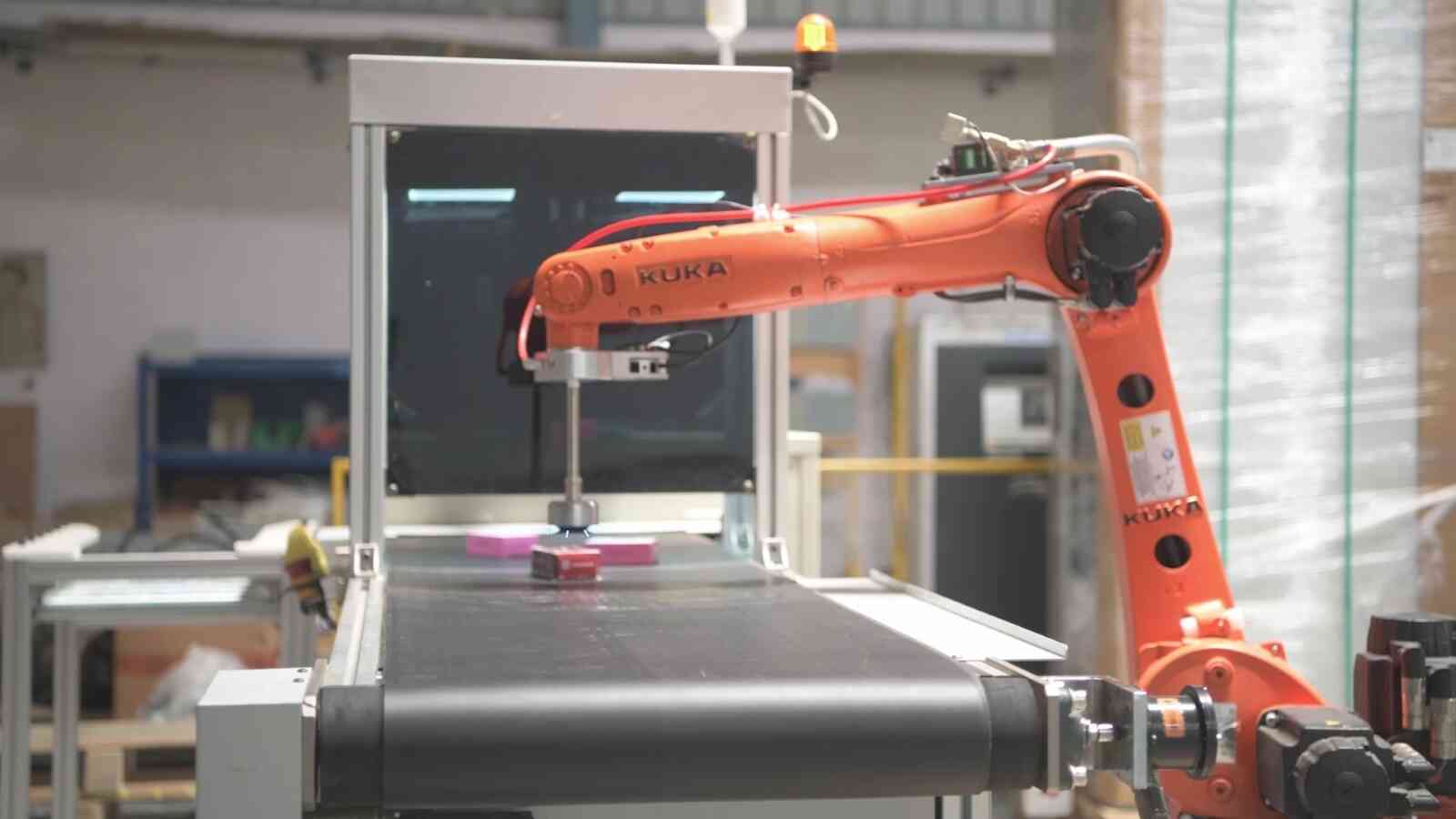

The Solution Layout., copyright Mech-Mind Robotics

Case Background

A company, Turkey’s Lovemark and the leader of home appliances, engages in the production of durable goods with innovative, eco-friendly, superior design and technology. It has a wide product range, including white goods, built-in appliances, electronics, small appliances, water and home heaters, and air conditioners.

At A company’s factory, the halogen detection of air compressors, the core component of air conditioners, is a tricky task because it requires the ability to repeat the same movement over and over again for several hours with exactly the same precision.

A company wanted robots to undertake this monotonous task. The benefits are apparent. Robots can add efficiency and throughput to the production line because they can work 24/7, non-stop. However, A company found that robots were still limited when conducting halogen detection.

Project Info and Challenges

Welding points to be detected in each compressor are random in size, position, and orientation. Halogen leak detection requires extreme accuracy and the workspace is quite tight and occupied with tangled condenser pipes (See Figure 1), so robots need to exactly “see” all the welding points and “understand” their surroundings, then “plan” an optimum path to avoid collisions, and thus they can finally conduct a successful inspection.

This is where Mech-Mind AI + 3D vision solution comes to play. Mech-Mind AI + 3D vision solution comprising machine vision, motion planning, and deep learning technology empowers robots with greater accuracy and dexterity, even in the face of high-precision detection and inspection tasks.

The Mech-Mind Solution

Solution Components: Mech-Mind introduced a high-accuracy industrial 3D camera Mech-Eye PRO S and AI-powered software suites–machine vision software Mech-Vision, robot control software Mech-Viz, and deep learning software Mech-DLK, paired with a UR5e robot, to optimize halogen leak detection.

The Mech-Mind AI + 3D vision solution is easy to set up and integrate and gives A company agility to handle product variations and fast changeovers. Thanks to Mech-Mind AI + 3D solution, A company has upgraded the halogen detection process, increased detection consistency, reduced waste and costs, and improved productivity.

Technical Requirements

- The 3D vision system should accurately recognize all welding points varying in position and orientation in AC condensers.

- The 3D vision system can differentiate high- and low-pressure welding points. (There is one high-pressure welding point and three low-pressure welding points in each compressor.) The former does not need to be inspected, while the latter needs inspection.

- The vision-guided robot can conduct the inspection in a tight workspace with high agility.

Technical Challenges

- Difficulty in generating high-quality point clouds: Reflections from the background can cause unwanted noises and lead to missing data in point clouds. (See Figure 3)

- Difficulty in accurate recognition: The occupied workspace increases the possibility of misrecognition. (See Figure 1) Welding points come in various sizes, shapes, and positions; welding points without detection requirements should be excluded during leak detection. A 100% recognition accuracy is a challenge for the vision system.

- High requirement on model training speed: The deep learning software needs to train models rapidly to deliver stable and accurate recognition of various welding points.

The Advantages of Mech-Mind AI + 3D Vision Solution

- Accurate 3D point cloud data: Using structured light technology, Mech-Eye PRO S Industrial 3D Camera outputs accurate 3D point cloud data, even for randomly-located welding points and compressors with dark surfaces, ensuring the precision locating of each welding point.

- Reliable recognition: Each welding point in the object image can be specially and separately identified. Mech-Vision Machine Vision Software delivers accurate recognition results of each welding point and outputs its exact positions for robots.

- Advanced deep learning software for complex vision tasks: Product and welding point variations pose a difficult challenge for accurate recognition. Mech-DLK Deep Learning Software trains models rapidly to respond to product and object variations and fast changeovers.

- Collision detection and path optimization: Mech-Viz Robot Programming Software plans the optimum robot path for precision inspection without collisions.

- Faster inspection speed: Mech-Vision filters out the high-pressure welding point based on the information of the Z-axis and sets a threshold for outputting recognition results. So it can output the recognition results of the low-pressure welding points that we need, thus optimizing the detection cycle.

- Traceability and real-time data management: Mech-Mind AI-powered software gathers data in real-time to manage detection results and review issues, thus reducing unplanned downtime and improving efficiency.

Workflow

- Mech-Eye PRO S, fixing statically, takes images of welding points and maps the surroundings.

- Mech-Vision provides the position information of all welding points for the robot at one time and guides the robot to arrive at the designated position. It ensures that the robot can conduct the halogen detection of all welding points one after another with only one data capture, optimizing inspection efficiency.

- Mech-Vision excludes the high-pressure welding point based on the information of the Z-axis and limits the recognition result number to three.

- The vision system identifies the positions of welding points based on 3D point clouds. Then the vision system calculates the distances between the welding points and the compressor center to filter the high-pressure point. (See Figure 4)

- Mech-Viz plans the optimal path for robots to understand complex environments and avoid collisions.

- Robots carry out the halogen detection of welding points.

- Once the end effector detects leaks, the system will trigger the alert, and the degraded product will be sent for repair.

- Repeat the procedures above until all compressors are detected.

The Results

- 100% recognition accuracy: Machine learning and deep learning algorithms enable the accurate recognition of welding points of almost all sizes and positions.

- Vision time (image acquisition + vision processing for 4 welding points) < 4 s: Industrial robots can conduct the halogen detection of more welding points per minute.

- Optimized cycle time: The built-in intelligent path-planning and collision detection algorithms plan the optimal path for robotic operation and thus improve the cycle time.

The Outcomes

AI technologies, including Machine Learning, Motion Planning, and Deep Learning, give traditional robots human-like functions. AI enables robots to use machine vision, control motion, and detect collisions to deliver a better performance in halogen detection. The integration of AI, 3D vision, and robots brings numerous benefits to A company.

- Increased inspection efficiency: Integrating AI technologies into industrial automation optimizes halogen detection. With improved detection consistency and precision, A company has increased productivity and thus yielded more profits.

- Lowered costs: Thanks to advanced AI technologies, such as deep learning, A company has handled product variations and fast changeovers without re-programming robotic applications, reduced unplanned downtime, and thus saved costs.

- Improved reliability: In a complicated industrial environment, Mech-Mind AI + 3D solution helps A company reduce the risk of on-site accidents. The robot, paired with AI technologies, can sense obstructions along its pre-programmed path and movement. In A company’s factories, robots can avoid collisions with objects and surroundings while conducting halogen leak detection.

AI for Multiple Challenging Tasks

Empowered by advanced vision technology and AI-powered software, robots are finding their way into unchartered territory, including random bin picking, assembly, and inspection. Mech-Mind is doing its best to push AI technologies to the limits and create robotics that fit seamlessly into more demanding industrial applications.

Case Studies / Industrial Robots / How Connected Robots are Transforming Manufacturing / AI in Robotics

How AI is Transforming Robotic Welding Programming in Metalworking Sector

Smart Welding - Success Case History

Mar 25, 2025 — Roboteco-Italargon, specialized in the development of cutting-edge robotic systems for the General Industry and Automotive sectors, has steadily expanded its presence in the welding robotics market over the past thirty years.

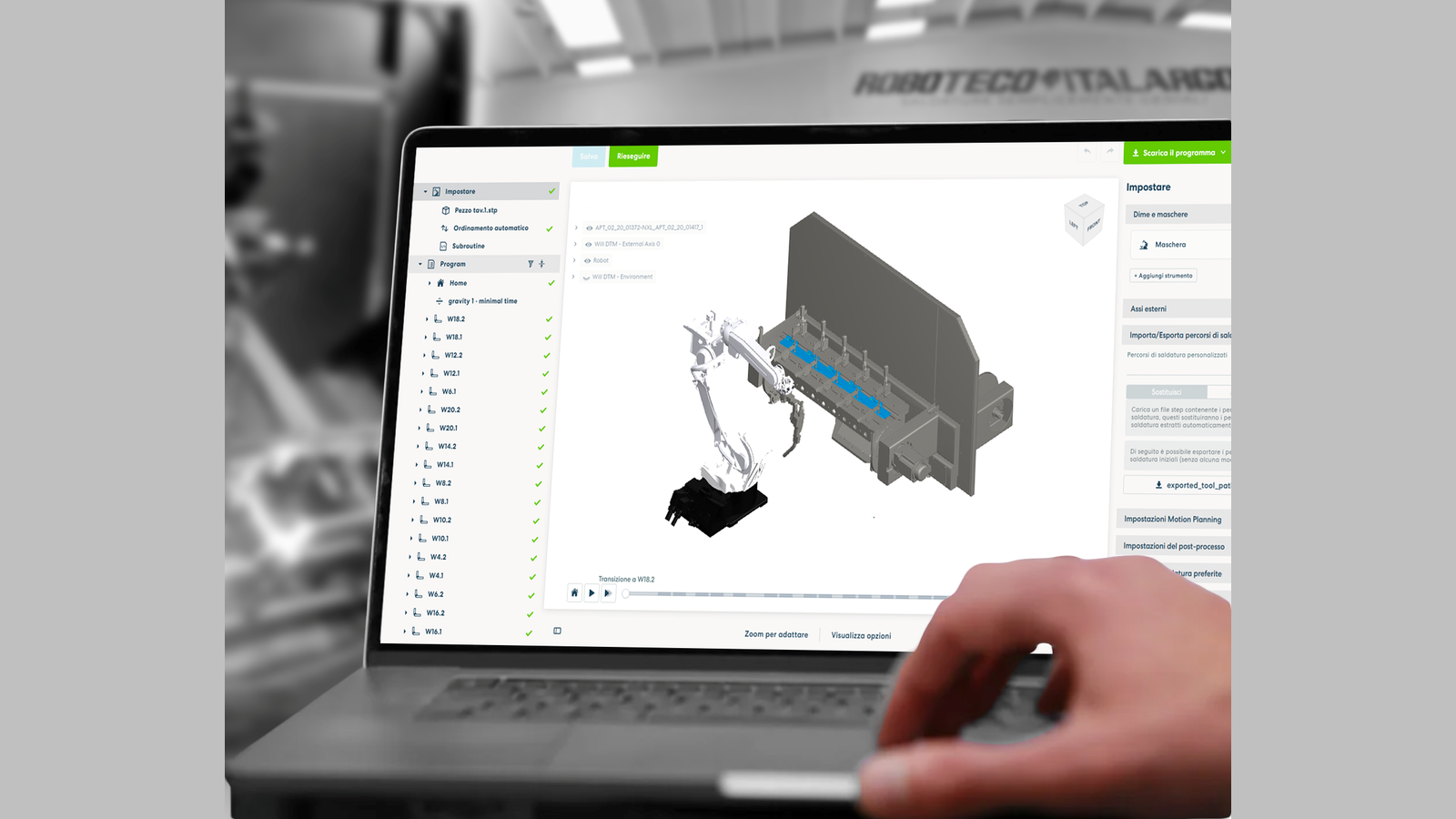

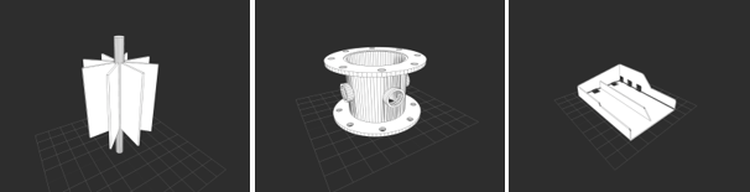

GeniusWeldPro (GWP) programming system copyright Roboteco

For three decades, it has been the exclusive distributor in Italy and, more recently, in Spain of Panasonic. multinational's anthropomorphic robots, both for arc welding and laser welding processes. By leveraging the most advanced software from its Japanese partners, Roboteco-Italargon is able to offer companies the best technological solutions and design customized systems tailored to each client’s specific needs.

The flagship of Panasonic technology, still unmatched nearly 20 years after its introduction to the global market, is TAWERS (The Arc Welding Robot System), an exclusive system that completely revolutionizes the concept of robotic welding.

Unlike conventional systems, where the robot’s CPU and the welding machine’s CPU communicate to execute welded joints, in the TAWERS system, a single CPU oversees and synchronizes all the elements involved in the welding process: the robot, the welding machine, and the wire feeder. This means that the robot controller has real-time access to all process variables.

Successful Case History

A recent application features Nexlam S.r.l., a young, dynamic, and technologically advanced company located in the heart of the industrial area of Castel Goffredo (Mantua), with over seventeen years of experience in metal sheet machining of stainless steel, carbon steel, aluminum, and brass. In a short time, it has enhanced its know-how and resources; its staff’s expertise ranges from laser cutting to punching, as well as mechanical machining, bending, welding, finishing, and assembly.

The welding and spot welding department, equipped with 10 workstations, is highly specialized in assembling all types of sheet metal components using MIG, MAG, TIG, and resistance spot welding technologies. Nexlam S.r.l. is undoubtedly a key player, capable of delivering high-quality, technologically advanced products. In its sector, metal fabrication, where efficiency and quality must go hand in hand, the company faced the need to optimize its production process. Specifically, the goal was to reduce the reliance on skilled operators for repetitive welding operations, allowing them to focus on more strategic activities. This need became even more pressing in a context marked by a growing shortage of specialized labor, a challenge affecting many companies in the industry.

Given this scenario, the company decided to explore automation solutions that could enhance productivity without compromising work flexibility.

Drawing on its experience and with a forward-looking approach, Nexlam S.r.l. identified the WILL (Welding Innovative Light Line) mini welding cell, offered by Roboteco-Italargon, as the ideal solution to meet its needs for efficiency, flexibility, and automated process management. This system proved to be the perfect tool for maximizing productivity and improving the quality of welded joints. Additionally, thanks to its compact dimensions (3.2 x 2 m), it was easily integrated into the workshop without requiring a reorganization of the production layout, ensuring a more efficient use of space.

The chosen mini welding cell model features a dual turntable with a manual station switch, enabling optimal welding operations management. The 600 mm rotation enhances flexibility and precision in component positioning. With a 1000 mm distance between fixture pin-pin and a payload capacity of 150 kg, the system can handle large workpieces, ensuring high capacity and versatility in production.

An added value of this compact solution is undoubtedly the presence of a Panasonic anthropomorphic robot equipped with the renowned TAWERS technology.

WILL stands out for its ease of use, offering a “ready-to-weld” setup simply by connecting the utilities. Its quick palletization and easy transport make it a practical and versatile solution. Additionally, the integrated Panasonic system enables precise control of welding parameters, ensuring optimal management of every stage of the production process.

In line with its Smart Factory 4.0 vision, Nexlam S.r.l. has enhanced its Panasonic robot-equipped mini welding cell by implementing the advanced GeniusWeldPro (GWP) programming system. This cloud-based software leverages Artificial Intelligence and generative algorithms to optimize the programming process.

The main reasons behind Nexlam S.r.l.’s decision to integrate GWP were twofold: the ability to significantly reduce welding robot programming times and the user-friendliness of the software, making it accessible even to less experienced personnel with minimal training.

This tool, used daily at Nexlam S.r.l., employs AI to analyze 3D CAD models, automatically identifying optimal weld joints and suggesting the best operational sequences to reduce cycle times. Thanks to GWP, the company has improved weld quality and achieved greater efficiency with a smoother, simplified workflow.

Operators upload the 3D CAD model directly into GWP, which autonomously generates the robot’s welding positions and transitions. In just a few steps, they can transfer the results to Panasonic’s DTPS (Desktop Programming & Simulation System) software, sending the carefully developed program to the robot, ready for execution. DTPS enables offline creation and modification of programs and direct CAD data import. With its collision detection and welding time calculation features, it maximizes process efficiency and safety, providing tools for motion sequence creation and optimization without halting production.

Confirming the strength of this investment, the client had the opportunity to test the system through practical trials conducted by specialized technicians at the Roboteco-Italargon Technical Center in Genoa. These tests demonstrated the quality and efficiency of the solution.

For its first investment in an automated welding system, the Mantuan company sought a cost-effective solution that would allow it to experiment with automation. The “Will and GWP” plug-in solution enabled Nexlam S.r.l. to gain greater versatility, efficiently managing even small production batches. This, in turn, allowed the company to enter sectors with high-quality standards and repetitive production, such as road transport manufacturing. With this solid foundation, the company can look to the future with prospects of further technological advancements and enhanced competitiveness in the industry.

The partnership between Nexlam S.r.l. and Roboteco-Italargon has proven to be the perfect fusion of vision and innovation, demonstrating how technological choices can drive progress while embodying the philosophy of the Mantuan company: "It's written Nexlam, it's read the future of sheet metal." This principle is reflected in its constant commitment to optimizing production processes and adopting cutting-edge solutions, opening new growth opportunities and generating value with a forward-thinking approach.

The photovoltaic industry contributes to global sustainability

Committed to the green and sustainable development

Mar 10, 2025 — Photovoltaic are green energy sources because they don't produce greenhouse gases or hazardous waste. As the world pays more and more attention to environmental protection, the application of photovoltaic power generation becomes more extensive.

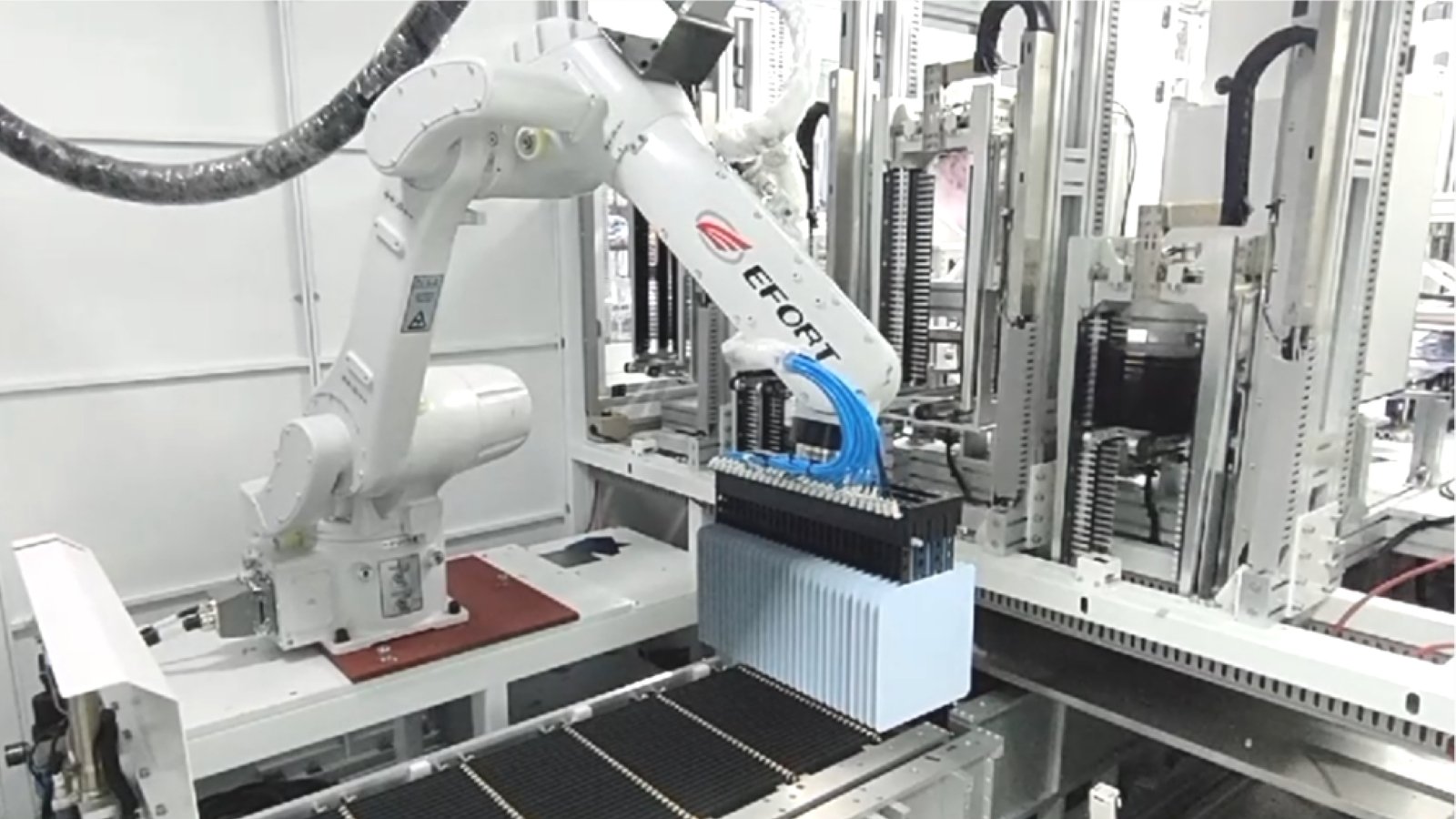

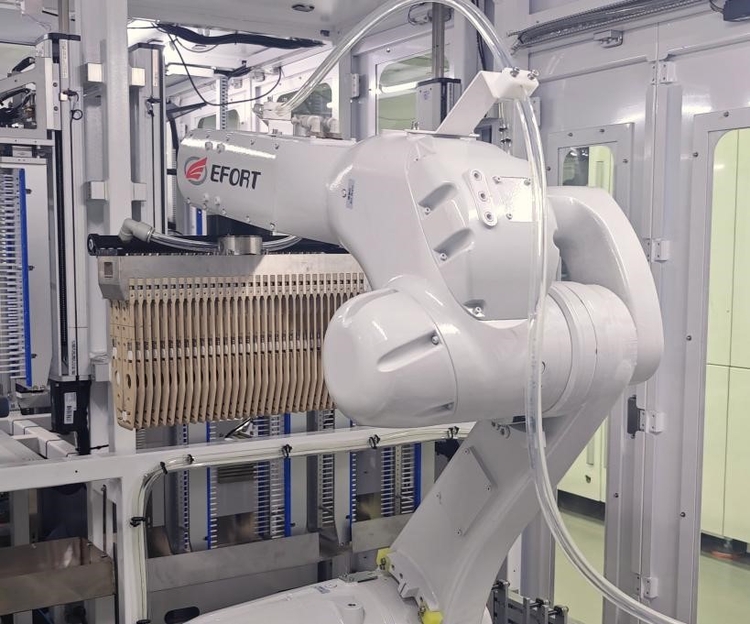

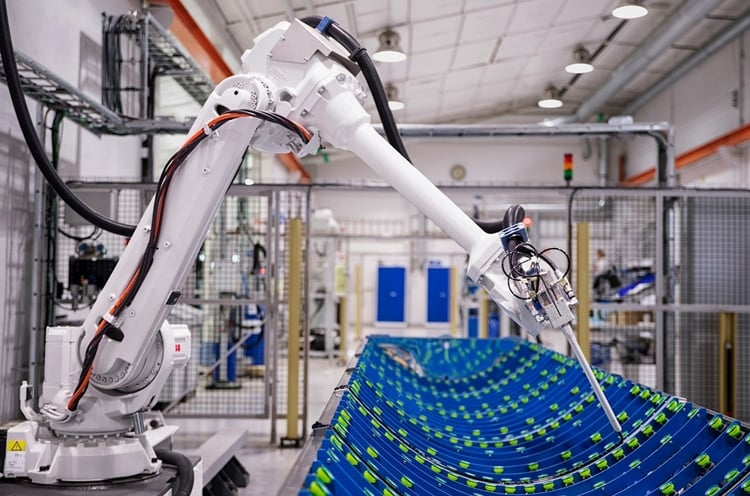

In the process of PECVD coating, using EFORT ER15 - 1400 to handle expensive and fragile silicon wafers can significantly reduce fragmentation rates while increasing production capacity © EFORT

According to the United Nations Framework Convention on Climate Change, the photovoltaic industry can generate about 7 trillion watts of electricity per year, which can meet the needs of about 70% of the world's homes, businesses and governments. The rapid development of the photovoltaic industry has promoted the progress of photovoltaic technology and materials, and the environmental and economic benefits it brings have gradually become prominent. Nowadays, the photovoltaic industry has become one of the fastest growing, most promising and most cost-effective sectors in the global energy sector.

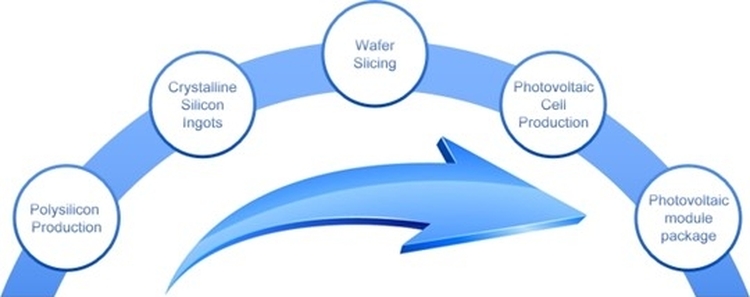

Photovoltaic manufacturing process and customer pain points

The thin photovoltaic cells are multi-layer structures, more complex than they seem. To complete the transformation from the most basic silicon material to the final photovoltaic cell module, it roughly needs to go through the main process processes such as industrial silicon, polysilicon, silicon wafers, cells, and modules. They're produced with hundreds of processes. High manufacturing costs once became the main reason for the slow spreading of photovoltaic. The challenges of downstream applications encourage upstream photovoltaic and equipment manufacturers to continuously improve the process, improve production efficiency and yield rates to reduce production costs.

Photovoltaic solutions (cell chip insertion)

PECVD coating is the core process of photovoltaic cell manufacturing. At the manufacturing site of TONGWEI Solar, the silicon wafers are stored in the graphite boat and enter the PECVD device port through the conveyor track. After receiving the sensor signal indicating that the graphite boat is in place, the EFORT ER15-1400 robot uses a special pneumatic clamp to accurately grab out and insert the silicon wafers between the graphite boat and the feeding mechanism.

To achieve better production efficiency, this seemingly simple "loading and unloading" action must be completed in the shortest cycle time and ensure that the expensive silicon wafers that have completed most of the process are intact, which will face many challenges:

- The compact layout of the production line and the limited movement space inside the equipment require more flexible posture;

- Silicon wafer is thin and brittle, easy to fracture, needs more accurate positioning accuracy and stability;

- Extremely clean working environment requires higher protection levels of robots.

The robot directly touches the silicon chip in the process of inserting/taking operation, and the previous achievements will be wasted if there’s a slight mistake, which puts forward higher requirements for the working rhythm, stability and accuracy of the inserting robot. Since Chinese industrial robots started late, domestic enterprises are relatively weak in the accumulation and application experience of robot core technology, therefore, domestic photovoltaic manufacturers once relied on imported products from internationally renowned robot manufacturers in this process. Based on the premise of sufficient market analysis and technical demonstration, ER15-1400 has achieved great performance in many user sites once launched. The users find that this Chinese domestic brand robot can meet the requirements of the working rhythm while running stably, and has better economy.

High protection is the basic requirement for robots in PECVD coating process environment. The product manager of ER15 described: "This product is completely enclosed in its shape of the design, its joint applies a unique double sealing technology, the wrist part reaches IP67 protection level, these measures can effectively avoid the leakage of internal lubricants caused by pollution losses, and also avoid the acidizing fluid during the operation of the robot life." ER15-1400 can be flexibly installed, in addition to the traditional ground installation method, it can also be integrated on the top and both sides of the equipment. It can fully achieve the handling operation of the silicon wafer between two graphite boats and equipment, combined with EFORT TMOVE (time optimal trajectory planning control algorithm) technology, which is a strong guarantee of stable and efficient production capacity.

"Accuracy and stability" are two very important technical requirements of the inserting process. The gap between the silicon wafer and the card slot in the graphite boat is as thin as hair. Considering the possible fixture tolerance, it is necessary to ensure that the trajectory repeatability of the robot is at least within 0.15mm. The highly rigid body design and EFORT's advanced robot motion control algorithms ensure that the robot's joints and arms maintain a good and smooth operating posture during the start, stop and high-speed operation, whether horizontal or vertical. The fixture can be accurately and smoothly inserted into the gap between the silicon wafers without any subtle shake, and the silicon wafers do not scratch when inserting into the narrow card slot of the graphite boat, thus ensuring accurate and stable insert work.

Pass along from customer trust and good reputation, ER15-1400 has gradually grown from a "strong novice" to a star product in the field of photovoltaic insert.

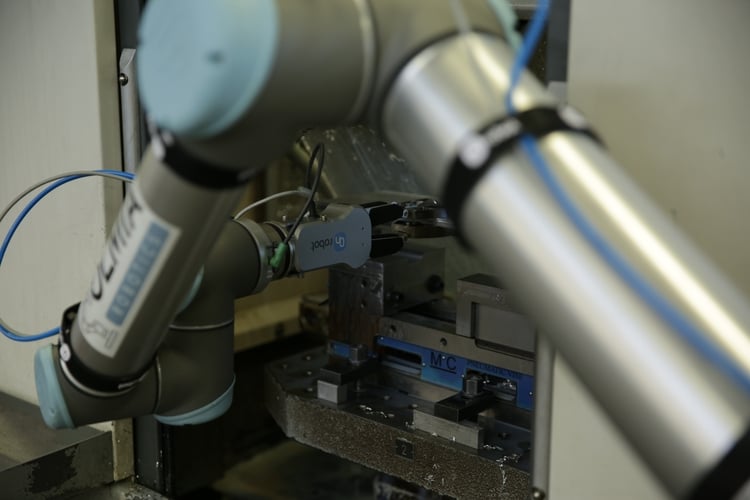

Cobots boost production 200% on welding and 600% on machine tending

Nov 04, 2024 — Ohio-based metal fabricator Raymath turned to Universal Robots to automate complex TIG welding, as well as MIG welding and CNC machine tending applications. The company’s new cobot applications significantly expanded production and helped Raymath meet customer needs, delivering ROI in less than 12 months.The business transformation

"Customers want to have fewer suppliers," says Greg LeFevre, CEO and President at Raymath. "So instead of a hundred suppliers, they would like to have ten that can do more. We wanted to satisfy those needs." LeFevre knew automation would be key to meeting Raymath's expanded productivity goals, but his experience was in high-volume, low-mix manufacturing: "It was very easy to automate when you make millions of a specific part. Moving into the fab-shop, sheet metal-type business, we're now looking at a large number of different parts, but in much smaller volumes," he explains. Because traditional automation doesn't lend itself to high-mix, low-volume, Raymath needed a much more flexible approach.

When the Raymath CEO found a UR certified systems integrator, THG Automation, close by, THG invited him to bring parts and get hands-on with the company’s UR cobot-based MIG welding system.

“Within the four hours that I was there, we programmed 20 weld points,” says LeFevre. “I was actually practicing and sampling on the parts that I was going to make. It proved to me without a doubt: if I can program this in four hours and actually have my parts running, this can work in our shop. I wrote the purchase order that same night.”

How they did it

In short order, Raymath installed four cobot welders from THG, handling MIG welding. Two robot operators now typically run two THG welding cells each. “The operators will typically run one robot, hit start, and while that one’s running, they’ll be loading the other one, and then will just jump back and forth,” says Raymaht’s robotics specialist, Nick Ogle. “Seeing all four cells run at the same time is pretty gratifying, knowing you’re pushing that much product out the door that much faster.”

Revolutionizing productivity

The cobots handle hard-to-staff processes with half the number of operators, and weld at twice the speed, resulting in 4X productivity improvement.

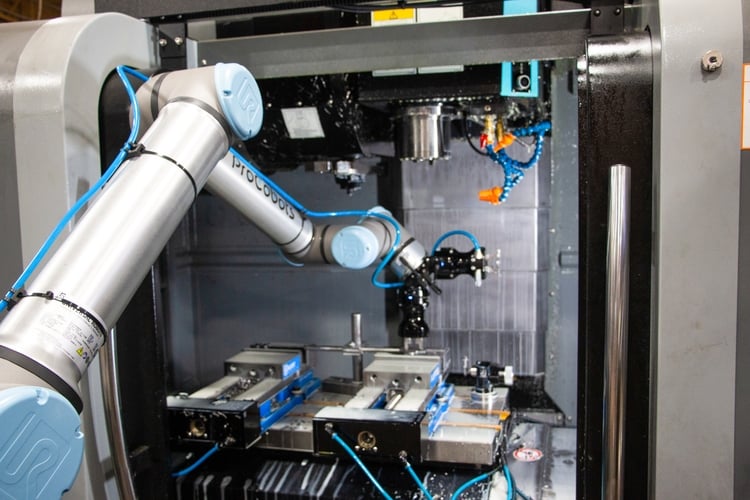

Raymath also turned to UR for its machine tending automation needs, adding the UR cobot-based ProFeeder machining cells from ProCobots to its two 3- and 5-axis Hurco CNC machines.

“We get 24 hours of machining time where we’ve never been able to get that before,” LeFevre states. That lights-out processing gives Raymath more than a 600% productivity boost in machining, getting double the hours with the same number of workers. This is especially important when workers—especially for third-shift work—are in short supply.

Expanding horizons triumph in overcoming welding challenges

Raymath can now take on business the company never had the manpower and the ability to do before. “Now that we can meet all of our customers’ needs, they are less like to go to a competitor who might also gain future business. It’s extremely valuable,” says LeFevre.

Complex aluminum welding was one of Raymath’s biggest challenges for growth, as it was all TIG welded by hand with precise welds on top and underneath, with difficult angles and heat settings, and multiple moving parts. After seeing success in MIG welding, LeFevre approached THG Automation for a TIG solution. “Once you get the precision and everything down, the THG unit can make a very, very good TIG weld, and can do it anywhere from two to six times faster than doing it by hand,” says the Raymath CEO.

Elevating excellence

For one aluminum part, the UR-based THG welding system has reduced weld times from 15 minutes per part manually to five to six minutes per part; for another, weld times shrunk from three to four minutes each to 30 to 40 seconds. While automated MIG welding can be applied to many different materials and applications, it may be difficult for manufacturers to justify two systems, especially at low volumes. With the THG cold wire feed push/pull TIG system, Raymath can weld both stainless and aluminum parts with the same system.

Precision and speed unleashed: UR Cobot revolutionizes TIG welding

The dexterity of the 6-axis UR cobot has dramatically increased the speed of the TIG welding process. “Before, the welder had to manually rotate and manipulate the fixture,” says a robotics specialist at Raymath, Nick Ogle. “Now the robot moves instead of the part moving, which means we can weld anywhere from two to six times faster than doing it by hand.”

Unleashing innovation: UR Website empowers with resources and simulators for efficient URCAP development

Beyond welding, Raymath also turned to UR for its machine tending automation needs, adding the UR cobot-based ProFeeder machining cells from ProCobots to its two 3- and 5-axis Hurco CNC machines.

Versatile welding mastery

The welds Raymath produces with the UR cobot-based TIG and MIG weld systems from THG Automation can vary from linear welds to circle welds to weave welds, uphill, downhill, and horizontal with the thickest material being up to about half an inch. “You can really do any position or kind of weld that you need to,” says Nick Ogle, robotics specialist at Raymath. “We can do circle welds now without stopping.”

Unlocking flexibility and simplified fixturing

With the UR cobots deployed in four weld cells, Raymath can have fewer people attend multiple units. “Other robots we looked at we had to fixture it to the nth degree, but we couldn’t justify building fixtures for all the different parts we have,” says Raymath President, Greg LeFevre. “With the UR cobots, we can simply put them on a welding table with minimal manual fixturing.”

Welding versatility

This ease of use is a key element of the THG design.

With UR’s open platform, THG Automation was able to create a customized robotic welding system with their own software embedded on the UR cobot’s own teach pendant, making the cobot welder easy to use, even for operators without previous robotics experience. Ogle, a manual welder by trade, simply moved the robot arm where it needed to be for the weld, and at the correct angle, using the teach pendant to save the point.

“UR and THG is the first time I’ve ever used collaborative robots, and I was very surprised at the ease of use,” says Ogle.

While THG provides one to three days of training for new systems, “A lot of times our customers will already have an application running in the welding before we even show up,” says THG Automation’s CEO Matt Hendey.

“When they call us down the road, it’s not about, ‘How do we make this thing still work?’ It’s about ‘Now I know how to do all this stuff, I want to get into the more advanced functionality of it.’”

UR10 Robots Revolutionize the Painting Process

Oct 31, 2024 — Brandt A/S, a well-established Danish company with over 60 years of experience in the painting industry, has taken a significant step towards innovation by implementing UR10 cobot solutions in its production process to achieve consistent quality and increase efficiency. With technology from UR+ partner Nordbo Robotics’ Mimic software, the robot can replicate the operator's movements one step at a time, then execute them with unprecedented precision. The implementation of the cobots has transformed the way the company handles painting tasks, leading to significant improvements in productivity and quality.

© Universal Robots

The business transformation

When Brandt A/S began its journey more than six decades ago, it specialized in car painting. Over the years, their tasks expanded to include industrial painting, and eventually, they became experts in powder coating.

Despite Brandt A/S's high quality and consistency standards, the company faced challenges with the manual painting processes that weren’t always able to deliver the accuracy and consistency the company aimed for. This initiated their search for possible automation solutions. "We have been searching high and low for robots that we could use in our touch-up department," says CEO of Brandt A/S, Rene Damgaard Hansen.

With the introduction of two new UR10 cobots in their powder coating process, Brandt A/S has been able to achieve an unprecedented level of accuracy and consistency. These robots can perform touch-up tasks that were previously difficult for manual operators to execute with the same precision. This integration of robotic technology has not only improved product quality but has also increased productivity by freeing up employees for more complex tasks.

How They Did It

Before the introduction of the cobots, employees performed manual spray painting 24/7. Now, Brandt A/S uses the Mimic technology from Nordbo Robotics that via a pose tracker sensor records the painters' movements and transfers them to the cobot, which performs touch-up tasks with unprecedented precision. The cobot works closely with operators and is designed to mimic their every move.

Universal Robots’ cobot is integrated with Nordbo Robotics programming unit and G.A. Hansen's Gema powder box. This enables seamless communication between the robot and peripheral equipment, resulting in consistent quality from run to run. Operators can easily create programs on the line track, and the cobot automatically detects the start of each item, ensuring continuous and efficient production.

"We started with two robots, but we also have other platforms where we need to implement them because we believe robots and digitization - that’s the future." noted Rene Damgaard Hansen, CEO of Brandt A/S

With the UR+ ecosystem, Brandt A/S has access to a wide range of components, software packages, and applications tested to seamlessly integrate with UR cobots, including Nordbo Robotics' Mimic software. This has enabled operators to program the cobot intuitively without needing in-depth technical knowledge. "We have taken the spray gun that the operators normally use and made it possible for them to program the robot just as they would usually use the spray guns," says CCO at Nordbo Robotics, Sabina Kethelz, emphasizing the user-friendly approach and minimal need for operator interaction, highlighting Universal Robots' focus on delivering a comprehensive and accessible automation solution. The system is also approved for Zone 22 with extended ATEX approval, which is an EU directive that the system complies with.

"In fact, you don't need to have a particularly large batch before it makes sense to implement a painting robot. And it doesn't require extensive training to use the robot" says Sune McDonald Bertelsen, Country Manager, Universal Robots.

Application of Autonomous Mobile Robots (AMRs) in the Front Section of Lithium Battery Factories

Oct 31, 2024 — IPLUSMOBOT recently collaborated with a company in the lithium battery industry. IPLUSMOBOT deployed an integrated hardware and software solution in the production workshop. This project helps operators handle repetitive tasks, ensures clean internal environments, significantly enhances factory automation, and meets the client's input-to-output ratio requirements.

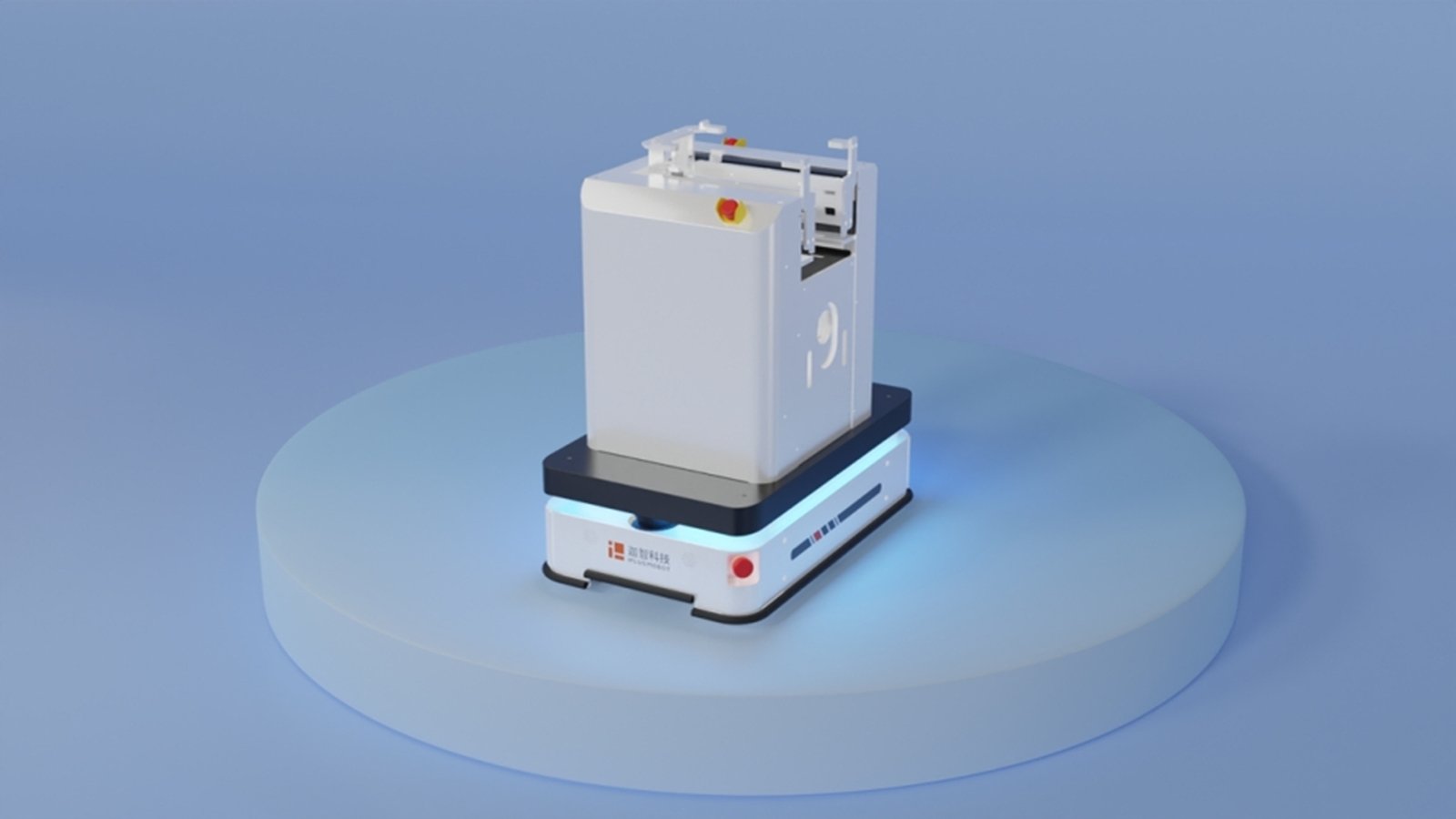

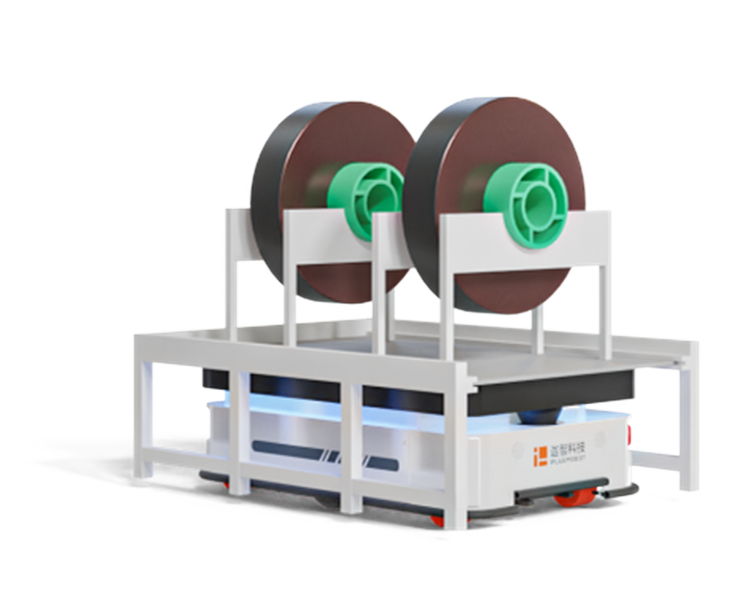

IPLUSMOBOT Cartridge-handling AMR

The client is one of the new energy industry giants, previously relied heavily on manual labor for material transfer and loading/unloading between various processes. As we know, high precision is required for AMR operations. Additionally, the factory logistics involves high-frequency handling, mixed human and vehicle traffic, narrow spaces, and frequent interactions with air showers and lifts, which demand high safety and stability performance from the AMRs.

Based on the actual layout and process requirements of the user's factory, IPLUSMOBOT developed a flexible, highly efficient intelligent manufacturing logistics solution. This solution includes multiple types of AMR carrying different materials in the battery production process, and with CLOUDIA Fleet Management System achieving On-Demand delivery, auto-charge and storage buffer management.

The CLOUDIA Fleet Management System seamlessly integrates with the user's WMS and MES systems, automatically receiving and dispatching task information. Different types of AMRs operate efficiently in a mixed tasks without human intervention, achieving digital, automated, and intelligent logistics throughout the handling process.

In the factory's rolling and cutting workshop, after material processing, the materials are placed on turnover racks. The CLOUDIA system issues task information, calling the standard AMR to receive the materials. The AMR autonomously positions the empty rack,docks and turnovers the full rack through roller shutters, air showers, and corridors to the first floor. It places the full rack at the designated receiving location and updates task execution status to the MES system in real time. The AMR then returns to receive the next task or follows the setting for charging, standby, or waiting for the next task.

Several Omnidirectional Cantilever Forklift AMRs are deployed in the coating and slitting sections for automated handling and logistics delivery of electrode rolls. The application of this AMR robot solves the industry problems of large load, high precision requirements and the need for a lot of manual assistance in electrode rolls loading and unloading scenarios; The AMRs use vision and laser fusion navigation technology to achieve ±5mm high-precision docking with onsite equipment and storage positions, meeting the user's production process requirements. Multiple safety measures ensure safe operation in narrow workshop passages.

Over ten cartridge-handling AMRs are used for loading, unloading, and buffering in the stacking area, ensuring autonomous transport and return of lamination cartridges. These AMRs dock with loading and unloading platforms with ±1mm precision, automatically moving full cartridges to the next stage and retrieving empty ones for return. In some workstations, the AMRs operate in narrow spaces, docking with machines in a confined 1,301mm aisle, handling loading and unloading tasks autonomously and efficiently. They communicate their status in real-time with equipment like air shower doors, elevators, and buffers, navigate through more than ten air shower and roller doors, operate seamlessly in mixed human-vehicle traffic, and autonomously call elevators to move between floors. The AMRs switch between visual and laser navigation based on the conditions on-site.

In the user's workshop, all AMR models work collaboratively through cross-map traffic management. This makes material information fully traceable, enabling data-driven reports for analyzing production bottlenecks and achieving lean manufacturing. This intelligent logistics solution has improved the previously cumbersome and chaotic manual handling processes, to reducing costs and increasing efficiency. Practical calculations show that the AMR deployment saves the workshop nearly 2 million yuan annually, eliminating the need for eight cartridge-handling trolleys. This meets the high-frequency material turnover requirements, significantly improving the timeliness and accuracy of logistics distribution and boosting production efficiency.

Welding cobot in use at Stöckl Maschinen- und Gerätebau

Aug 06, 2024 — For Stöckl Maschinen- und Gerätebau in Schliersee (Germany), the moment finally came when a neighbouring customer placed a large-scale order: this prompted the company to venture into robot-based welding – with a Weld4Me cobot complete cell by Yaskawa.

Sky loungers by Holztec-Leitner © Yaskawa

Success came literally overnight for Holztec-Leitner based in Schliersee in Upper Bavaria: no sooner had company boss Franz Leitner placed his self-designed, hand-made swing and relaxation loungers made of larch and spruce in an online shop, the first orders started to come in. And numbers have been growing ever since: subject to copyrighted design throughout Europe, the Himmelsliegen (“sky loungers”) are no longer just at home on the banks of Lake Schliersee but on numerous terraces and in gardens and parks as far afield as Mallorca and Italy.

After the initial surprise, Holztec-Leitner quickly realised that a partner was needed to supply the high quantities required on an ongoing basis. The partner was to take over production of the high-quality pivot mounts made of solid metal: the sky loungers are not only attractive and comfortable, they also rotate by 360°.

Successful collaboration

In his search for a suitable specialist, Franz Leitner first tried his luck on his own doorstep in Schliersee – and found just what he was looking for at Stöckl Maschinen und Gerätebau GmbH. “That’s how it all started,” says Kamil Kowalski, one of two Stöckl managing directors, looking back on the beginnings of this successful collaboration.