Cobots boost production 200% on welding and 600% on machine tending

Nov 04, 2024 — Ohio-based metal fabricator Raymath turned to Universal Robots to automate complex TIG welding, as well as MIG welding and CNC machine tending applications. The company’s new cobot applications significantly expanded production and helped Raymath meet customer needs, delivering ROI in less than 12 months.The business transformation

"Customers want to have fewer suppliers," says Greg LeFevre, CEO and President at Raymath. "So instead of a hundred suppliers, they would like to have ten that can do more. We wanted to satisfy those needs." LeFevre knew automation would be key to meeting Raymath's expanded productivity goals, but his experience was in high-volume, low-mix manufacturing: "It was very easy to automate when you make millions of a specific part. Moving into the fab-shop, sheet metal-type business, we're now looking at a large number of different parts, but in much smaller volumes," he explains. Because traditional automation doesn't lend itself to high-mix, low-volume, Raymath needed a much more flexible approach.

When the Raymath CEO found a UR certified systems integrator, THG Automation, close by, THG invited him to bring parts and get hands-on with the company’s UR cobot-based MIG welding system.

“Within the four hours that I was there, we programmed 20 weld points,” says LeFevre. “I was actually practicing and sampling on the parts that I was going to make. It proved to me without a doubt: if I can program this in four hours and actually have my parts running, this can work in our shop. I wrote the purchase order that same night.”

How they did it

In short order, Raymath installed four cobot welders from THG, handling MIG welding. Two robot operators now typically run two THG welding cells each. “The operators will typically run one robot, hit start, and while that one’s running, they’ll be loading the other one, and then will just jump back and forth,” says Raymaht’s robotics specialist, Nick Ogle. “Seeing all four cells run at the same time is pretty gratifying, knowing you’re pushing that much product out the door that much faster.”

Revolutionizing productivity

The cobots handle hard-to-staff processes with half the number of operators, and weld at twice the speed, resulting in 4X productivity improvement.

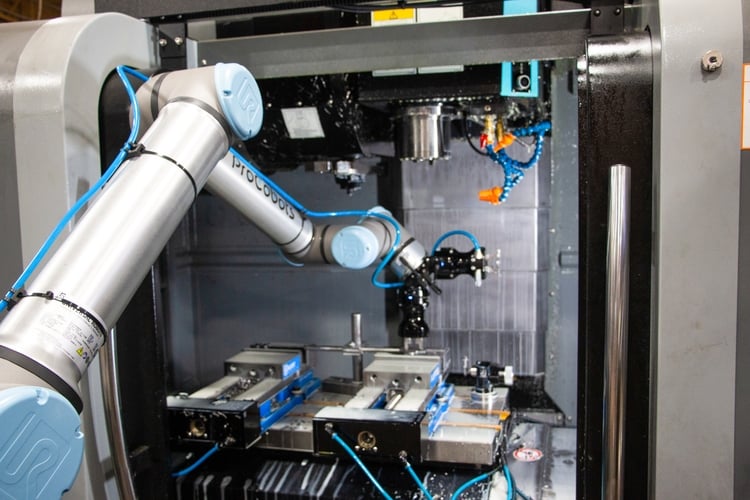

Raymath also turned to UR for its machine tending automation needs, adding the UR cobot-based ProFeeder machining cells from ProCobots to its two 3- and 5-axis Hurco CNC machines.

“We get 24 hours of machining time where we’ve never been able to get that before,” LeFevre states. That lights-out processing gives Raymath more than a 600% productivity boost in machining, getting double the hours with the same number of workers. This is especially important when workers—especially for third-shift work—are in short supply.

Expanding horizons triumph in overcoming welding challenges

Raymath can now take on business the company never had the manpower and the ability to do before. “Now that we can meet all of our customers’ needs, they are less like to go to a competitor who might also gain future business. It’s extremely valuable,” says LeFevre.

Complex aluminum welding was one of Raymath’s biggest challenges for growth, as it was all TIG welded by hand with precise welds on top and underneath, with difficult angles and heat settings, and multiple moving parts. After seeing success in MIG welding, LeFevre approached THG Automation for a TIG solution. “Once you get the precision and everything down, the THG unit can make a very, very good TIG weld, and can do it anywhere from two to six times faster than doing it by hand,” says the Raymath CEO.

Elevating excellence

For one aluminum part, the UR-based THG welding system has reduced weld times from 15 minutes per part manually to five to six minutes per part; for another, weld times shrunk from three to four minutes each to 30 to 40 seconds. While automated MIG welding can be applied to many different materials and applications, it may be difficult for manufacturers to justify two systems, especially at low volumes. With the THG cold wire feed push/pull TIG system, Raymath can weld both stainless and aluminum parts with the same system.

Precision and speed unleashed: UR Cobot revolutionizes TIG welding

The dexterity of the 6-axis UR cobot has dramatically increased the speed of the TIG welding process. “Before, the welder had to manually rotate and manipulate the fixture,” says a robotics specialist at Raymath, Nick Ogle. “Now the robot moves instead of the part moving, which means we can weld anywhere from two to six times faster than doing it by hand.”

Unleashing innovation: UR Website empowers with resources and simulators for efficient URCAP development

Beyond welding, Raymath also turned to UR for its machine tending automation needs, adding the UR cobot-based ProFeeder machining cells from ProCobots to its two 3- and 5-axis Hurco CNC machines.

Versatile welding mastery

The welds Raymath produces with the UR cobot-based TIG and MIG weld systems from THG Automation can vary from linear welds to circle welds to weave welds, uphill, downhill, and horizontal with the thickest material being up to about half an inch. “You can really do any position or kind of weld that you need to,” says Nick Ogle, robotics specialist at Raymath. “We can do circle welds now without stopping.”

Unlocking flexibility and simplified fixturing

With the UR cobots deployed in four weld cells, Raymath can have fewer people attend multiple units. “Other robots we looked at we had to fixture it to the nth degree, but we couldn’t justify building fixtures for all the different parts we have,” says Raymath President, Greg LeFevre. “With the UR cobots, we can simply put them on a welding table with minimal manual fixturing.”

Welding versatility

This ease of use is a key element of the THG design.

With UR’s open platform, THG Automation was able to create a customized robotic welding system with their own software embedded on the UR cobot’s own teach pendant, making the cobot welder easy to use, even for operators without previous robotics experience. Ogle, a manual welder by trade, simply moved the robot arm where it needed to be for the weld, and at the correct angle, using the teach pendant to save the point.

“UR and THG is the first time I’ve ever used collaborative robots, and I was very surprised at the ease of use,” says Ogle.

While THG provides one to three days of training for new systems, “A lot of times our customers will already have an application running in the welding before we even show up,” says THG Automation’s CEO Matt Hendey.

“When they call us down the road, it’s not about, ‘How do we make this thing still work?’ It’s about ‘Now I know how to do all this stuff, I want to get into the more advanced functionality of it.’”