Automated pick, pack and palletization

Error free packaging

Jul 07, 2021 — Manual end of line packaging operation in a warehouse involves challenges such as Labor shortage, Longer idle times, Slower pick speeds resulting in conveyor stoppage and Order packing errors.

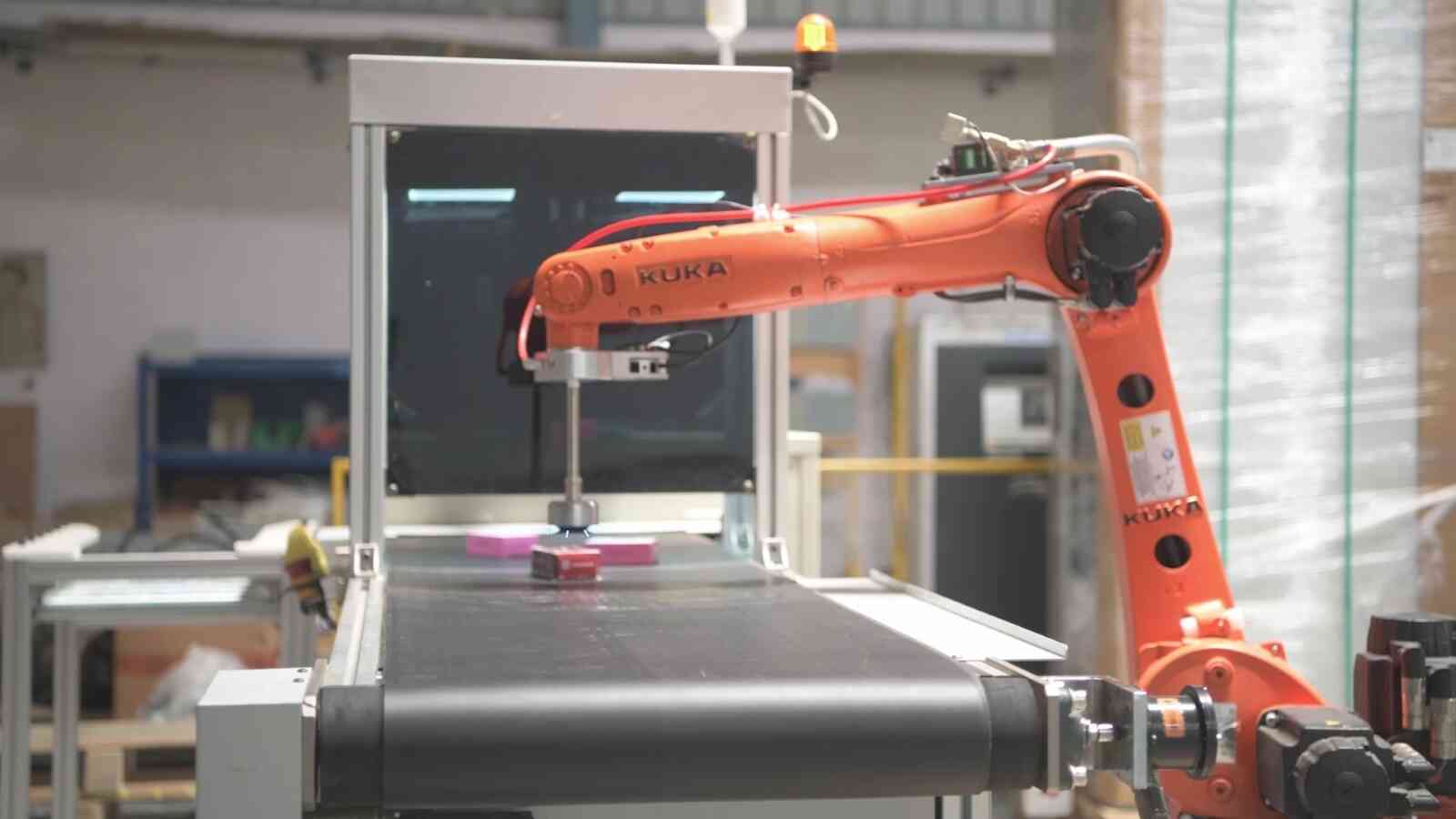

The robot detects the ordered items on the conveyer © Wipro

Solution

Wipro devised a smart packing solution with the features such as End-to-end orchestration by software, UI based order creation and tracking, Integration of robot, conveyor and computer vision, AI based volume estimation and stacking pattern generation in real time and Zero robot teaching.

Process

The order is placed through the order fulfilment system. Once the order is triggered, the robot erects a carton from the stacked cartons. The robot system determines the volume of the empty carton that has been erected using computer vision. Then, formulates the optimum stacking pattern in the carton based on the order using Artificial Intelligence.

Interfaced with Wipro’s robotics software platform, the robot detects the ordered items on the conveyer, picks them on the go and places them as per the AI generated stacking pattern in the carton. Any outliers such as damaged or unordered items are segregated into a separate area. In case the items that are to be packed last arrive early on the conveyor, the robot moves them to a temporary storage and continues packing in the AI generated pattern.

Once the carton is packed with the ordered items, the robot closes the flaps and seals the cartons. The packed cartons are then palletized.

Benefits

- Error free packing solution

- Elimination of manual robot teaching

- Elimination of labor dependency