Application of Autonomous Mobile Robots (AMRs) in the Front Section of Lithium Battery Factories

Oct 31, 2024 — IPLUSMOBOT recently collaborated with a company in the lithium battery industry. IPLUSMOBOT deployed an integrated hardware and software solution in the production workshop. This project helps operators handle repetitive tasks, ensures clean internal environments, significantly enhances factory automation, and meets the client's input-to-output ratio requirements.

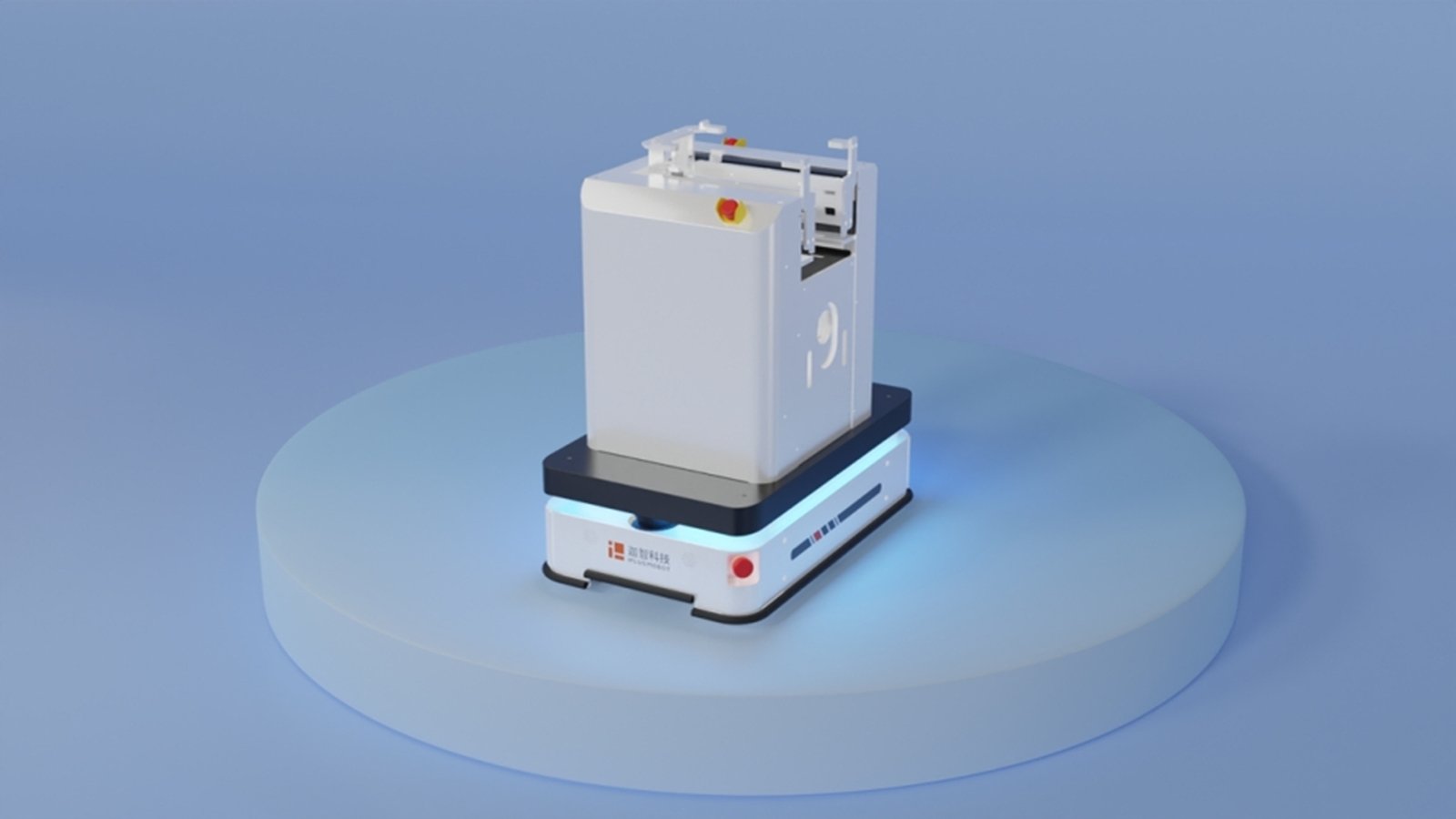

IPLUSMOBOT Cartridge-handling AMR

The client is one of the new energy industry giants, previously relied heavily on manual labor for material transfer and loading/unloading between various processes. As we know, high precision is required for AMR operations. Additionally, the factory logistics involves high-frequency handling, mixed human and vehicle traffic, narrow spaces, and frequent interactions with air showers and lifts, which demand high safety and stability performance from the AMRs.

Based on the actual layout and process requirements of the user's factory, IPLUSMOBOT developed a flexible, highly efficient intelligent manufacturing logistics solution. This solution includes multiple types of AMR carrying different materials in the battery production process, and with CLOUDIA Fleet Management System achieving On-Demand delivery, auto-charge and storage buffer management.

The CLOUDIA Fleet Management System seamlessly integrates with the user's WMS and MES systems, automatically receiving and dispatching task information. Different types of AMRs operate efficiently in a mixed tasks without human intervention, achieving digital, automated, and intelligent logistics throughout the handling process.

In the factory's rolling and cutting workshop, after material processing, the materials are placed on turnover racks. The CLOUDIA system issues task information, calling the standard AMR to receive the materials. The AMR autonomously positions the empty rack,docks and turnovers the full rack through roller shutters, air showers, and corridors to the first floor. It places the full rack at the designated receiving location and updates task execution status to the MES system in real time. The AMR then returns to receive the next task or follows the setting for charging, standby, or waiting for the next task.

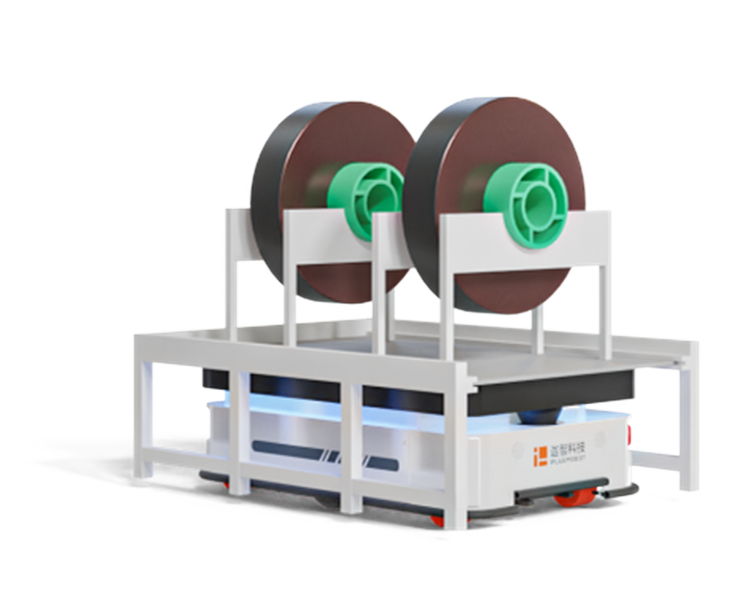

Several Omnidirectional Cantilever Forklift AMRs are deployed in the coating and slitting sections for automated handling and logistics delivery of electrode rolls. The application of this AMR robot solves the industry problems of large load, high precision requirements and the need for a lot of manual assistance in electrode rolls loading and unloading scenarios; The AMRs use vision and laser fusion navigation technology to achieve ±5mm high-precision docking with onsite equipment and storage positions, meeting the user's production process requirements. Multiple safety measures ensure safe operation in narrow workshop passages.

Over ten cartridge-handling AMRs are used for loading, unloading, and buffering in the stacking area, ensuring autonomous transport and return of lamination cartridges. These AMRs dock with loading and unloading platforms with ±1mm precision, automatically moving full cartridges to the next stage and retrieving empty ones for return. In some workstations, the AMRs operate in narrow spaces, docking with machines in a confined 1,301mm aisle, handling loading and unloading tasks autonomously and efficiently. They communicate their status in real-time with equipment like air shower doors, elevators, and buffers, navigate through more than ten air shower and roller doors, operate seamlessly in mixed human-vehicle traffic, and autonomously call elevators to move between floors. The AMRs switch between visual and laser navigation based on the conditions on-site.

In the user's workshop, all AMR models work collaboratively through cross-map traffic management. This makes material information fully traceable, enabling data-driven reports for analyzing production bottlenecks and achieving lean manufacturing. This intelligent logistics solution has improved the previously cumbersome and chaotic manual handling processes, to reducing costs and increasing efficiency. Practical calculations show that the AMR deployment saves the workshop nearly 2 million yuan annually, eliminating the need for eight cartridge-handling trolleys. This meets the high-frequency material turnover requirements, significantly improving the timeliness and accuracy of logistics distribution and boosting production efficiency.