In AI in robotics research, Dr. Susanne Bieller, IFR General Secretary noted that programming and integration account for 50-70% of the cost of a robot application. Robot programming was a huge problem for a long time. It was time-consuming and economically unviable for high-mix production as the cost of switching from one product to another was very expensive.

However, the situation is changing dramatically. Thanks to new technologies such as AI and machine vision, robots can be cost-effective even for custom projects or one-of-a-kind products.

Let's take a look at how the two approaches, traditional and new, work and understand the difference.

How to program with teach-pendants or offline systems (the traditional method)

Let's take for example one part and select several seams. The first is a curved seam with complex geometry. The second is a round seam, which is best done with a positioner (rotating the part while welding). The third seam is a 4-part seam with difficult reach for the robot.

Teach-pendant programming (also it’s called online programming) was developed by robot manufacturers themselves. Using a teach pendant, the operator moves the robot to the desired positions and records the movements. You need to program each point of the robot's trajectories. It should be noted that each robot manufacturer has their own program code and their own approach to programming. If a programmer knows how to work with a robot of brand A, this knowledge may not be applicable to brand B robots.

Traditional teach-pendant programming takes 1 hour 35 minutes to weld these three seams.

Another disadvantage of this method is downtime. Programming takes place inside a cell, meaning the cell will not function during this time. To solve the issue of downtime, offline programming was invented. The idea here is to remove the need to program inside of the cell, moving the process to a virtual environment instead. The programmer still writes the code, but all of this happens inside a virtual twin of the cell.

However, this way of programming created a new challenge that online programming did not present. Virtual and real cells are always slightly different:

- Real robots and real working zones may differ from their virtual copy;

- The parts themselves may differ from the perfect 3D model, due to deviations arising in pre-assembled;

- Real fixtures and clamps may differ too.

Thus, after creating a program in a virtual environment, the programmer still needs to test it on a real robotic cell, using a teach pendant.

So the current method is efficient for mass production where you have to program a part once and then weld it thousands/millions of times.

How to program with AI and machine vision (the new method)?

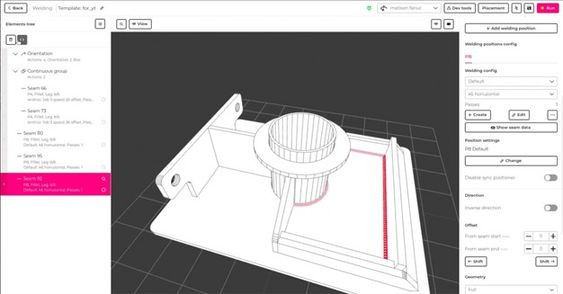

You just upload a 3D model of the part (from the CAD). The system automatically finds all the weld joints on it. Then you choose the welds and the parameters you need (work and travel angles, offsets, weaving, etc.). No programming is required. Mathematical algorithms automatically generate the robot trajectories. This happens in minutes.

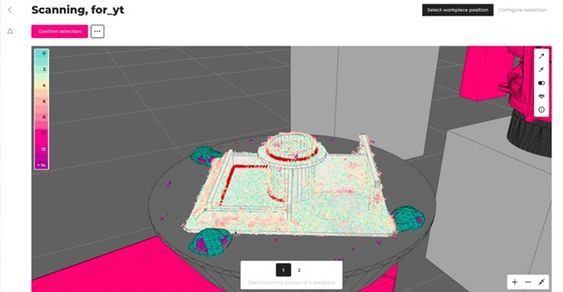

The next step is scanning the part using machine vision. The algorithms compare the previously uploaded 3D model and the real part. The system finds all possible deviations and adapts the robotic trajectories on-the-fly.

In addition, welding often involves fixtures for parts. Robots are also able to "see" them and avoid collisions with them.

The system only takes 10 minutes to set the robot task for welding the three seams described above. It is 10 times faster than the traditional way.

This ease and speed of programming allow simply to switch from one product to another and make robots cost-effective for high-mix production and even one-of-a-kind products.

Welding Robots for High-mix Production

Here are some examples of the effective use of welding robots for high-mix manufacturing with the new programming method.

EXCAVATOR BUCKET

Previously, programming a welding robot for one bucket took days or weeks. Now programming takes 10 minutes.

AUGER

The smart system automatically coordinates the simultaneous movements of the auger and the torch to create a uniform, continuous weld without programming. No need to flip or reposition parts.

BRIDGE STRUCTURES

Steel Bridge Manufacturer welds more than 50 different part types per month in a single robotic cell. They don't have programmers on staff.

IFR Secretariat

The General Secretariat is responsible for the daily management of IFR and the coordination of all major activities, events and collaboration. The General Secretariat handles all questions regarding IFR membership.

Dr. Susanne Bieller

IFR General Secretary

Phone: +49 69-6603-1502

E-Mail: secretariat(at)ifr.org

Silke Lampe

Communication Manager

Phone: +49 69-6603-1697

E-Mail: secretariat(at)ifr.org

Credits · Legal Disclaimer · Privacy Policy ·World Robotics Terms of Usage · © IFR 2026