ROS Gains Foothold in the Robotics Ecosystem

ROS, the Robot Operating System, is an open source software framework, more recently referred to as a development kit for robotics application development. For over 10 years ROS has become a standard platform to enable developing teams across technical domains and industries to transition capabilities from the research lab to the field or factory floor by providing access to proven algorithms, developer tools, and interfaces for the various components that are needed for the next generation robotics deployments. It has enabled disparate components to work in a tightly integrated way to solve complex tasks or realize capability where dynamism is a key element of the environment or application.

The success of ROS is a testament to the success of open source as a vehicle for advancing capability and the community that has built up the vast code base while demonstrating over a decade of capability. This success is helping to convert new adopters as ROS transitions to ROS 2 while introducing more robust features. As the robotics community transitions from the original implementation of ROS to ROS 2 and further deployments enter the wild, it helps to look back at the history of ROS and the related ROS-Industrial initiative to help contextualize the current trends and think about the exciting future ahead.

ROS and Willow Garage

ROS got its start in California’s Silicon Valley at Stanford University in the U.S., as the foundational framework within the 2008 Willow Garage PR2 robot. From there, after Willow Garage was shut down, a nonprofit was started to support ROS and the complimentary simulation framework Gazebo. Since then, Open Robotics has led the maturation of ROS, enabling and growing a global community that is multi-domain, supporting the teaching of robotics, single student projects, multi-institution collaboration, competitions, and of course new products in the marketplace. The value has been proven over and over again by leveraging an open source, business friendly license model, that accelerates time to market. This has enabled more efficient returns by enabling derisking and more agile end-use application development. ROS provides consistent flexibility to enable efficient integration with other ecosystems, software tools, or hardware by providing well documented interfaces, and messaging architectures.

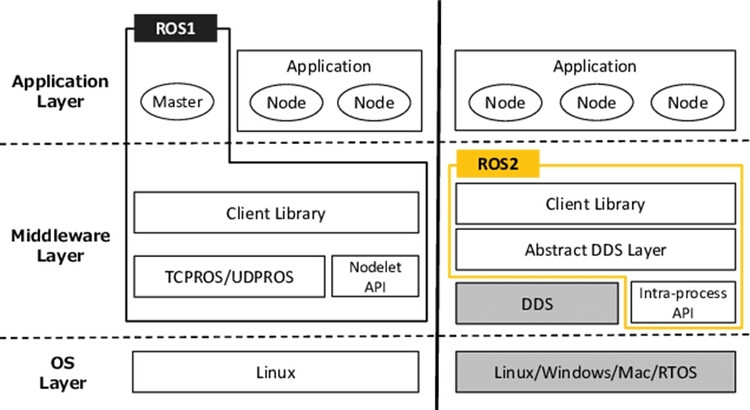

After the success of ROS, the downloads, the products, and the sizeable community, it was time to look at the shortcomings. This led to the development of ROS 2. The initial release of ROS 2, in December 2018, sought to address several limitations in ROS 1. The robustness and determinism in dynamic environments, security, and support for embedded systems were key drivers for the redesign that went into ROS 2. The other key element was the selection of the Data Distribution Service (DDS) communication standard, which has been proven in critical infrastructure, military, and financial system applications. This has addressed a number of the challenges around reliability and enabling more robust performance and best in class security.

The ROS-Industrial Story

In parallel to the progress of ROS, an initiative was launched in 2012 to understand if ROS could be leveraged for industrial applications. Southwest Research Institute, a nonprofit, applied R&D organization based in San Antonio, Texas, had been building first-of-a-kind robotic systems for the previous 20 years. Each custom application would require significant software rewrite due to the nature of industrial robotics creating proprietary ecosystems, including their own proprietary programming languages. Shaun Edwards of SwRI, in cooperation with Yaskawa Motoman, co-located at Willow Garage to create the first instance of an industrial manipulator being controlled by ROS. This commit and creation of a simple message and the Motoman Driver were the first ROS-Industrial commits, and the ROS-Industrial open source project was born. In 2013, Paul Hvass, also of SwRI, instantiated the ROS-Industrial Consortium. The Consortium’s mission is to give direction to the ROS-Industrial open source project and drive synergies amongst universities, OEMs, solution developers and providers, and end-users. The ROS-Industrial Consortium Americas has been managed by Matt Robinson of SwRI since 2017, overseeing enhancements to open source resources and the growth by more than double of the Consortium membership.

Since the inception ROS-Industrial has sought to bring high mix/low lot capability to industrial end-users, while reducing barriers to entry both in industrial robotics as well as open source robotics. Over the course of its history ROS-Industrial specifically has provided resources that include applications, training, standards for interfaces, as well as physical systems and demonstrations aligned with industry needs.

Managing the Transition from ROS 1 to ROS 2 for Industry

As part of the vision for ROS for industry, which is fed by feedback from the Consortia members and the industrial community, is to manage the transition and support for ROS and ROS 2. There have been numerous documented industrial successes with ROS, and collaboration projects furthering foundational capability for industry. However, as ROS 2 becomes the new standard, a new approach for support has been required. Therefore ROS-Industrial has sought to create key enabling content decoupled from the ROS version as feasible, and provide interfaces for the specific ROS version that is being used. This enables those that are not ready or have high performing systems in ROS 1 to continue to leverage improvements in core libraries. Conversely as new users adopt ROS 2, they can count on core libraries that have been proven in industrial applications. The main thing is to create as big of a tent as possible, and not leave users behind simply because they cannot migrate to ROS 2, while still enabling continuous improvements in the ecosystem as more adopters come on, creating higher performing and robust solutions for the whole community.

ROS Success Stories in Industry

The impact of ROS-enabled solutions has been well documented. Spirit AeroSystems has shared their success in leveraging ROS for high-mix part painting. Due to their position as a supplier to numerous OEMs for aerospace, they inherently have the challenge of producing parts of many varieties. In this example ROS enables them to do on the fly Scan-N-Plan painting, improving their efficiency and removing the burden of creating unique robot programs for all the parts for which their operations were responsible. Since then, Spirit AeroSystems has grown a strong team of internal developers where ROS is a key enabler in their Industry 4.0 vision and how they manage total value stream productivity and quality.

Another case study is looking across two recent development initiatives. The first is the Advanced Automation for Agile Aerospace Applications (A5) program. The United States Air Force funded this initiative to create a flexible agile platform and software that could easily go from one air depot sustainment task to another without complex programming. Currently the program is in a follow-on phase to execute radiographic inspection for obstructions in air inlets, after performing sanding repair operations in a previous phase.

While this application is compelling, the real impact has been the associated software framework. This framework built on ROS has recently been extended to two new applications as part of the ARM Institute, which serves as a Manufacturing Innovation Institute in a public-private partnership funded by the U.S. Department of Defense. The first program, Mobile Autonomous Coating Application for Aircraft Sustainment sought to create a mobile robotic paint solution for high-mix aerospace parts. The second, Autonomous Coating with Realtime Control and Inspection, sought to do real time paint process planning based on observed features and adjusting the paint process from a learning framework informed by extensive computational fluid dynamics. What made these programs possible, each only a year in length, is that they were simply extensions of the A5 framework. The modular nature with consistent interfaces enabled new components, or software modules, to be added and the core framework re-used to create these two new applications for two different end users.

Innovations in the European Union and Asia-Pacific

Since 2013, the ROS-Industrial open source project and affiliated Consortia have grown to be a global initiative. Fraunhofer IPA in Stuttgart, Germany stewards a ROS-Industrial Consortium European Union (EU) since 2014 and the Advanced Remanufacturing Technology Centre in Singapore is headquarters for ROS-Industrial Consortium Asia-Pacific (AP).

Within the European Union the recently completed ROSin project was funded by the EU’s Horizon 2020 research and innovation program and aimed to amplify its impact by making ROS-Industrial better and even more business-friendly and accessible. The success of this program has furthered robust interfaces supported by OEMs, the creation of new applications around welding and logistics, and numerous new startups leveraging ROS in their products within the EU and beyond.

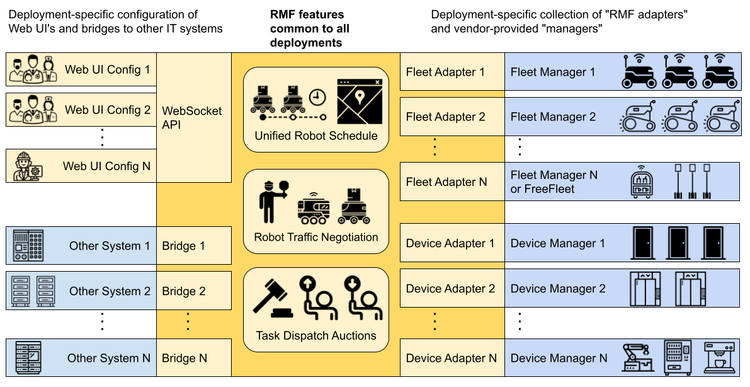

ROS-Industrial Asia-Pacific has been creating its own momentum and contributing to the global ecosystem. The biggest program has been supported by Open Robotics, the curators and maintainers of ROS and the Singapore government. The Open Robotics Middleware Framework (Open-RMF) is a free, open source, modular software system that enables sharing and interoperability between multiple fleets of robots and physical infrastructure, like doors, elevators and building management systems. The work was recently recognized as one of the 2021 RBR50 Robotics Innovation Award Honorees. Interoperability has been a mainstay of one of the benefits of ROS and this work highlights the power of enabling rich interoperability across multiple intelligent devices.

Supporting Further Industry Adoption

It is clear that ROS has now gained a foothold in the robotics ecosystem. The ability to stretch from education to research labs to novel product developers, to the top tech companies and end-users on shop floors leveraging ROS to create solutions is truly compelling. Numerous companies have built and delivered products that leverage ROS or are using ROS as part of the development workflow and they include the likes of Clearpath, Fetch, now part of Zebra Technologies, Samsung, Apex.ai, Sony, Robotnik, Bastian Solutions, and more. There are ever more resources to support industry to adopt ROS. These include workshops, education and training, working examples, and regular community and developer meetings and forums to engage with others using these tools, and even conferences, both around ROS and for each global region for ROS-Industrial.

As ROS 2 progresses in parallel with industry adoption, there has been increased focus on safety and quality. New resources are emerging and practices to ensure enhanced security and performance for systems that leverage ROS. There are numerous working groups that are open and active seeking to build a broad coalition to improve the framework to support requirements and enable an ecosystem that is scalable for industry, education, government, and beyond. Recent initiatives around ROS for space only add to the requirements that will push ROS relative to capability and reliability due to the requirements for software in that domain.

We look forward to seeing the continued growth of ROS in industrial use and deployment and believe strongly in a community that focuses on the foundational building blocks that provide a foundation that reduce the reinvent the wheel, enabling end users with challenges to get right to the problem solving and having tools, resources and software ecosystem that just works. We encourage those interested in advancing the state of industrial robotics to consider looking into ROS and the ROS community, including projects like ROS-Industrial, and the specific community around ROS for industry. Let’s continue to provide resources to enabling richer industrial capability aligned with the needs and requirements of the factories of tomorrow.

IFR Secretariat

The General Secretariat is responsible for the daily management of IFR and the coordination of all major activities, events and collaboration. The General Secretariat handles all questions regarding IFR membership.

Dr. Susanne Bieller

IFR General Secretary

Phone: +49 69-6603-1502

E-Mail: secretariat(at)ifr.org

Silke Lampe

Communication Manager

Phone: +49 69-6603-1697

E-Mail: secretariat(at)ifr.org

Credits · Legal Disclaimer · Privacy Policy ·World Robotics Terms of Usage · © IFR 2026