Historically, robots have been standalone machines, each with their own vendor-specific programs. When robots ‘talk’ to other machines – generally through an external controller - the communications interface must be programmed specifically for each type of machine. Code developed for one make of robot controller cannot generally be transferred to another, even if the task being carried out – for example, instructing the robot to run at a specific speed - is exactly the same.

Manufacturers today are increasingly implementing automation strategies to increase productivity, cut costs through just-in-time manufacturing and respond to the demand for smaller, customised production runs. As a result, more and more machines are connected, and produce data which can be stored and analysed to improve production performance. This has led to a significant increase in the complexity and overhead of programming. Many manufacturers struggle to gain an overview of the status of all the machines on the production floor along one common parameter (for example speed and position of robot axes) since each vendor specifies these parameters differently.

To address this issue, the mechanical engineering industry association in Germany and Europe (VDMA) teamed up with the OPC (Open Platform Communications) Foundation to create a common interface for all types and components of robot systems* such as industrial robots, mobile robots, control units and peripheral devices. The joint initiative aims to establish standard interfaces to enable the extraction and exchange of information from different robot manufacturers in a standardised way, irrespective of the manufacturer.

The OPC Robotics Companion Specification is a communications technology model which allows manufacturers to associate different terms or blocks of code with one common semantic definition. For example, the term ‘serial number’ surfaces data on the robot’s serial number, irrespective of how this is specified in the proprietary robot program.

The OPC Robotics Companion Specification is being developed in stages by a working group of around 35 companies comprising robotics suppliers, control manufacturers, integrators and automotive companies that use robots. Part 1 – covering asset management and condition monitoring – was released in September 2019. It enables organisations to surface information on the operational status of their robot systems, down to the individual component level. Companies can monitor the condition of their robot systems against given parameters – for example motor temperature, load or time cycle. This information can then be integrated into applications pertaining to use cases such as predictive maintenance, in which machine performance data is analysed to detect if a specific part is likely to need maintenance. Manufacturers can then plan maintenance before the situation becomes critical and the machine malfunctions, potentially causing expensive production downtime. The specification provides detailed information about the main electrical and mechanical parts such as part number, brand name and serial number. Technicians can therefore see exactly which part needs to be changed if a machine is not adhering to given thresholds, rather than discovering this only during the maintenance process.

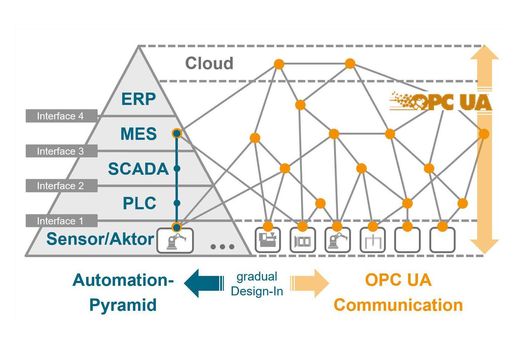

Part 1 covers ‘vertical integration’ – referring to the robot and any technology that controls it, such as a Manufacturing Execution System (MES) or Programmable Logic Controller (PLC). Subsequent parts of the Robotic Companion Specification will cover geometrical descriptions of a robotic system (tracking the movement of the robot in a 3D space) and various aspects of controlling the robotic system, for example up /downloading and starting /stopping programs, confirming system messages and switching drives on and off. Having a standard semantic reference for each of these tasks enables manufacturers to easily gain a real-time view of production. For example an automotive manufacturer tracking an order for 10 cars of Type A and 5 of Type B can see exactly what stage of completion the order has reached for car type A by tracking downloads for the various programs needed to produce car type A. These programs will typically be distributed across multiple robot systems that are also working on car type B.

Other OPC Universal Architecture Companion Specification groups within VDMA are developing models to enable similar vendor-independent specification for other machines such as injection moulding machines and machine vision systems. Once available, these will enable horizontal integration between robots and other machines in an automation process.

To find out more about the OPC Robotics Companion Specification, see the following videos:

https://youtu.be/-xgFKg1hXTg

https://youtu.be/ZdLVFI_1S54

Further information is also on the VDMA Website here

* OPC robotics covers a motion device system that includes any existing or future robot type, control systems and software

IFR Secretariat

The General Secretariat is responsible for the daily management of IFR and the coordination of all major activities, events and collaboration. The General Secretariat handles all questions regarding IFR membership.

Dr. Susanne Bieller

IFR General Secretary

Phone: +49 69-6603-1502

E-Mail: secretariat(at)ifr.org

Silke Lampe

Communication Manager

Phone: +49 69-6603-1697

E-Mail: secretariat(at)ifr.org

Credits · Legal Disclaimer · Privacy Policy ·World Robotics Terms of Usage · © IFR 2026