In the post-pandemic era, in response to the concerns on workforce and productivity, the global manufacturers will need to actively set out a forward-looking strategy to expands the scope for the use of safe collaborative robots.

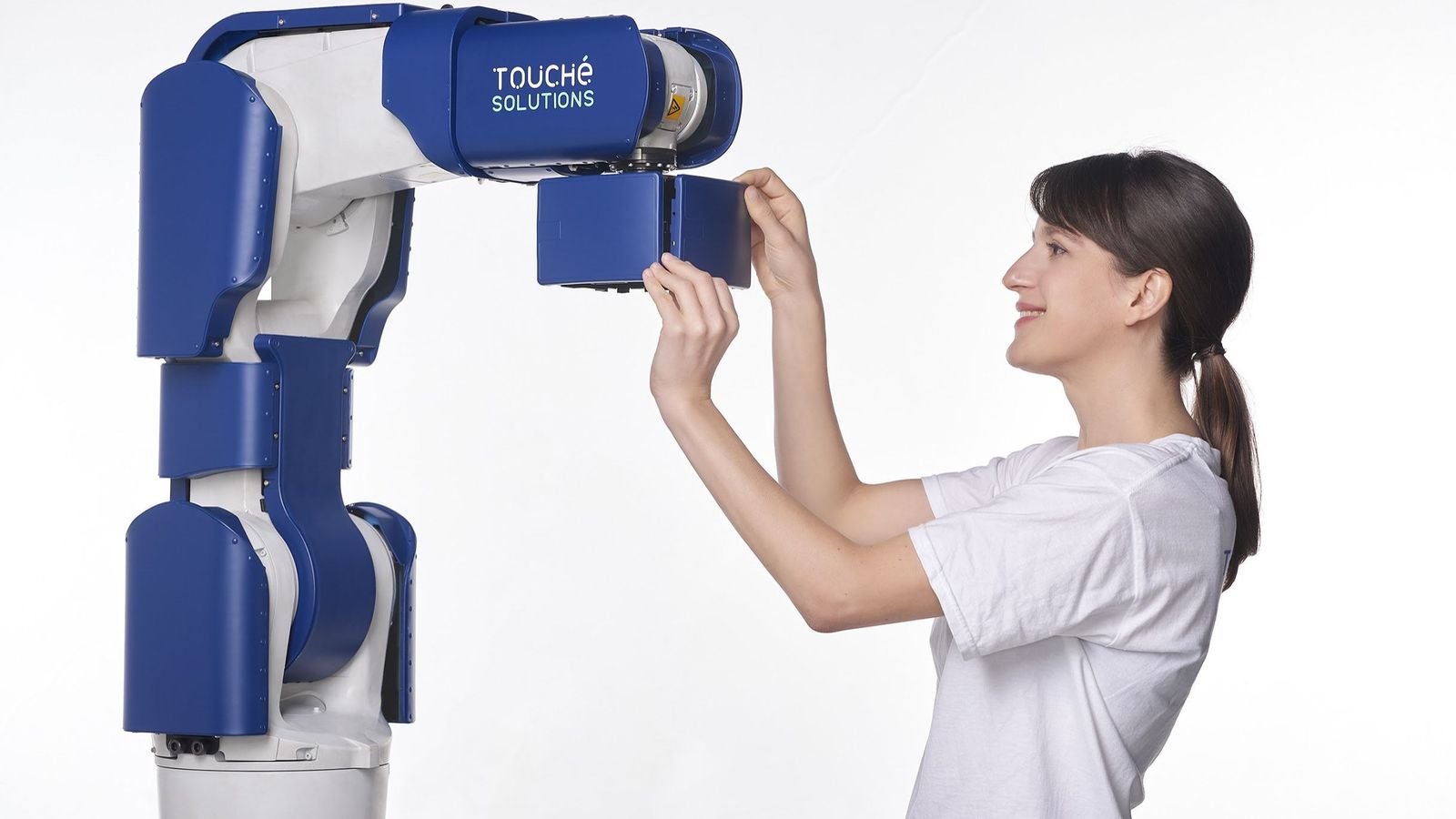

Due to limited resources and land, how factories can quickly set up, relocate or increase production capacity with their existing plant and workforce is a highly concerned issue. Therefore, Touché Solutions launched the safe, efficient and easy to install T-Skin, the world’s first tactile sensor safety technology to obtain CE ISO 13856-3 certification. Once installed, T-Skin immediately enables industrial robots to collaborate with human workers. Moreover, it also enhances workplace safety, makes quick production line reconfiguration possible without being constrained by the fixed workspace, and increases productivity to stay competitive.

During the post-COVID era, solutions for safe, efficient, and quickly implementable production line modification are required

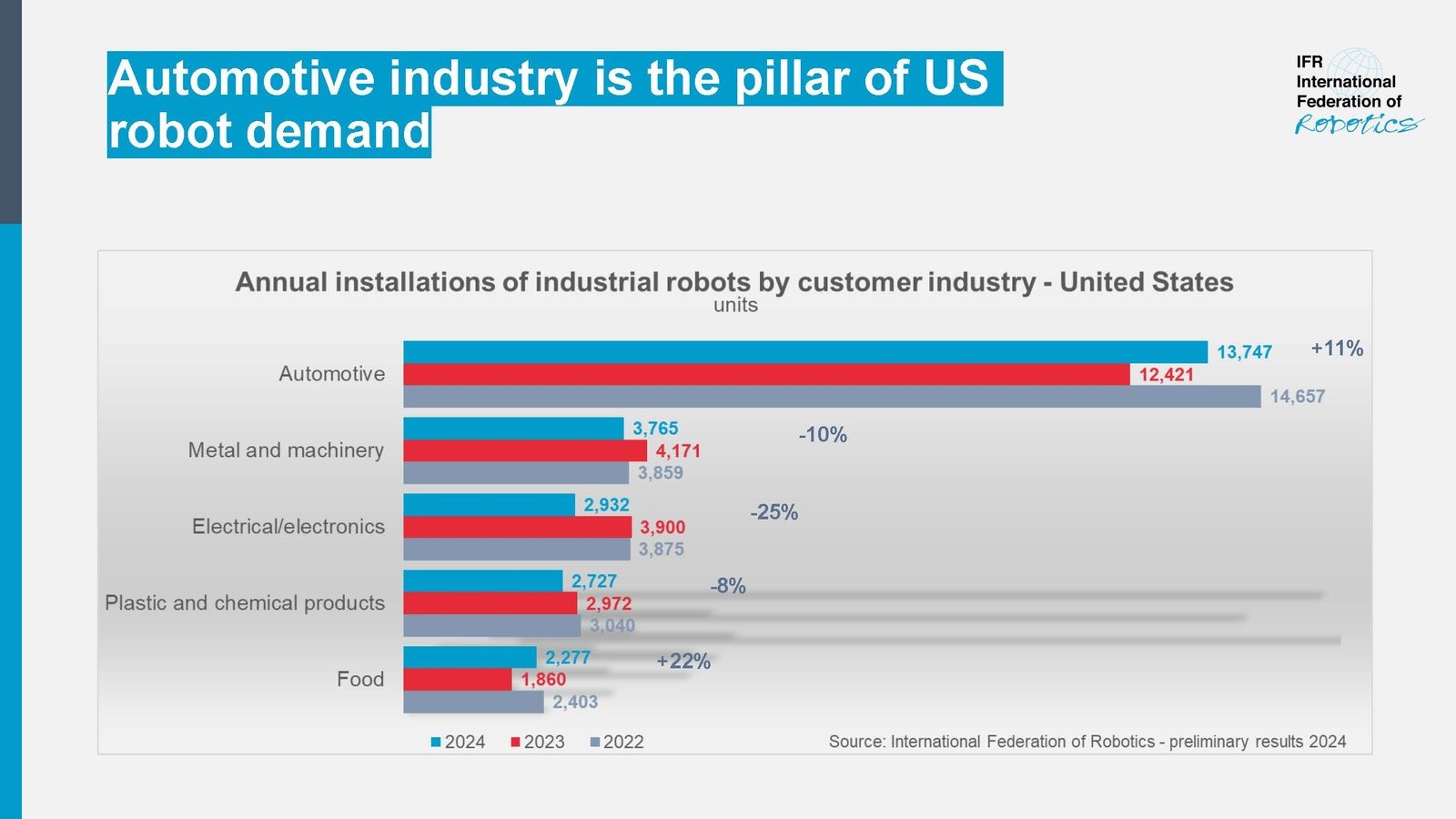

Touché Solutions C.E.O., Andrew Lu “In the post-pandemic era, it’s a must for workers to keep a safe distance on the production line. To meet the post-pandemic demand, in manufacturing industries such as automobile and electronic assembly or metal stamping, factory managers need the solutions to quickly increase level of automation or modify production line to increase the productivity and efficiency. Among all, safe human-robot collaboration is the best solution.”

“This is why fast and easy installation is an important design concept of T-Skin. It quickly gives any robot arm safety protection for use in any industrial environment. After completion of a risk assessment, a robot installed with T-Skin ensures the workplace safety of human staff during collaboration and protect collaborative robot arms from being damaged during operation. In response to the post-pandemic workforce planning, the safe human-robot collaboration to deploy robots installed with T-skin for the repetitive tasks is the biggest boon to the production line.” Moreover, after being upgraded as collaborative industrial robots, it’s possible to remove robots from fences to optimize the use of workplace that increases production efficiency per unit space.

T-Skin (formerly called Contact Skin), Touché Solutions’ pioneering technology for use on a robot arm, is an actual touch-and-stop system. In April, 2020 the system obtained the European Union’s CE ISO 13856-3 and ISO 13849-1 certification: its product safety and functional safety were both certified.

To provide more comprehensive protection for users, besides T-skin, Touché Solutions has also developed the T-Skin Pad Module. With its modular design, it can be quickly assembled to fit the end effectors of different sizes. When installed, the safety protection mechanism is more comprehensive.

New impetus- CE certification and rebranding Touché Solutions

Touché Solutions (formerly Mechavision) will soon mark its third anniversary. Company chairman Camus Su: “The feedback on our products from the market over the last three years has given us even greater confidence in tactile technology and its applications for future robots. We have chosen the time of obtaining CE certification to rebrand as Touché Solutions, reflecting our commitment to make headway in the international market and become the leading brand for tactile sensor technology. We will continue providing solutions for human-robot collaboration, and help clients achieve their production capacity and quality optimization goals.”