Another year is coming to an end - a year of many ups and downs. In January, there were hopes around the globe for a return to normal. In the recent weeks, Europe is speeding towards new lockdowns and restrictive measures to fight the pandemic. Last-minute cancellations of trade fairs felt more like the prior year. At the same time, China seems to have the situation under control by compromising freedom of travel and other restrictive measures intended to keep infections low.

Dear Reader,

Another year is coming to an end - a year of many ups and downs. In January, there were hopes around the globe for a return to normal. In the recent weeks, Europe is speeding towards new lockdowns and restrictive measures to fight the pandemic. Last-minute cancellations of trade fairs felt more like the prior year. At the same time, China seems to have the situation under control by compromising freedom of travel and other restrictive measures intended to keep infections low.

2021 brought about the phrase "new normal", but we long for the "old normal", being able to travel freely and meet each other in person.

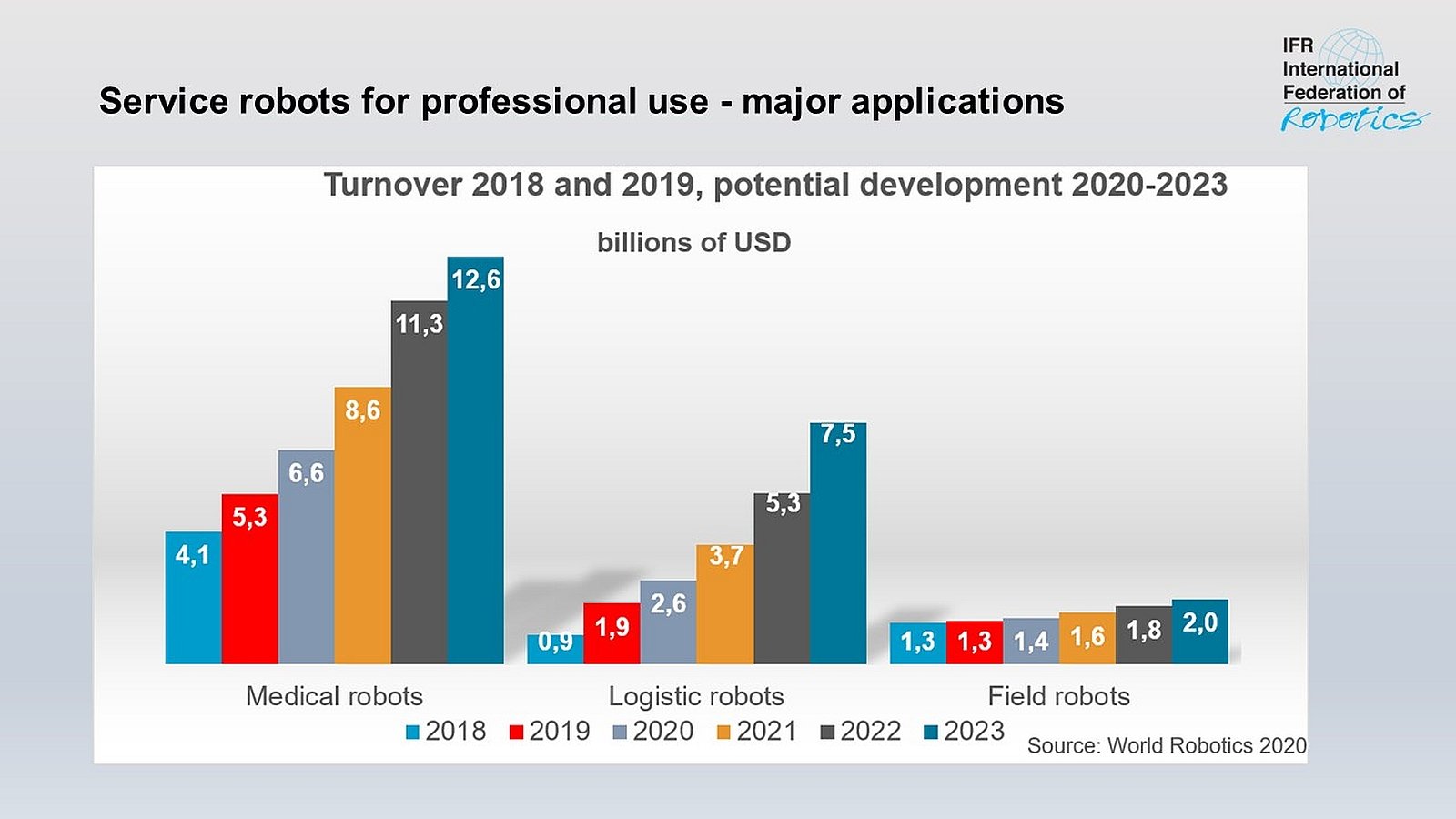

Looking to our market there are encouraging signs. Robotic sales are on the rise. A record 3 million industrial robots are operating in factories around the world. Despite the global pandemic, robot sales grew slightly in 2020 at a rate of +0.5%. China led the rebound ahead of the Americas and Europe. Overall, 2020 was the third most successful year on record for the robotics industry. The outlook for 2021 is even more optimistic with a double-digit growth projected.

Several market trends are propelling the growth outlook. Localization and regionalization of supply chains will make them more resilient by bringing production closer to the customer. New business models such as Robots-as-a-service (RaaS) or Pay-as-you-use lower entry barriers. The growing supply of low-cost robots will further reduce the total cost of ownership (TCO) opening robot usage in new markets. Lastly, “Batch size 1” production allows customized product variations at the unit costs of serial production. These trends will be a driver for advanced robotics systems and provide a platform for fully digitalized production from order to delivery. The case for robots has never been stronger.

Looking to COP 26, sustainability in manufacturing is no longer a "nice-to have". This initiative will increasingly impact investment decisions where robotics have a multitude of impact:

First, robots are crucial for cost-efficient production of green technology, for example solar panels and batteries for electric vehicles.

Second, robotic production reduces the share of rejects, lowering the carbon footprint by improving input-output ratios.

Third, robot manufacturers play a crucial role in further reducing the overall energy consumption of production systems, by designing energy-efficient units and end-of-arm tools.

With a bit of luck, 2022 will be the year where we are back meeting face to face, with all three major international robotics events taking place within the first six months. We are looking forward to our industry coming together again for lively discussions, Executive Roundtables and physical IFR meetings.

I wish you a peaceful holiday season and a happy and successful start to the New Year.

Milton Guerry

IFR President