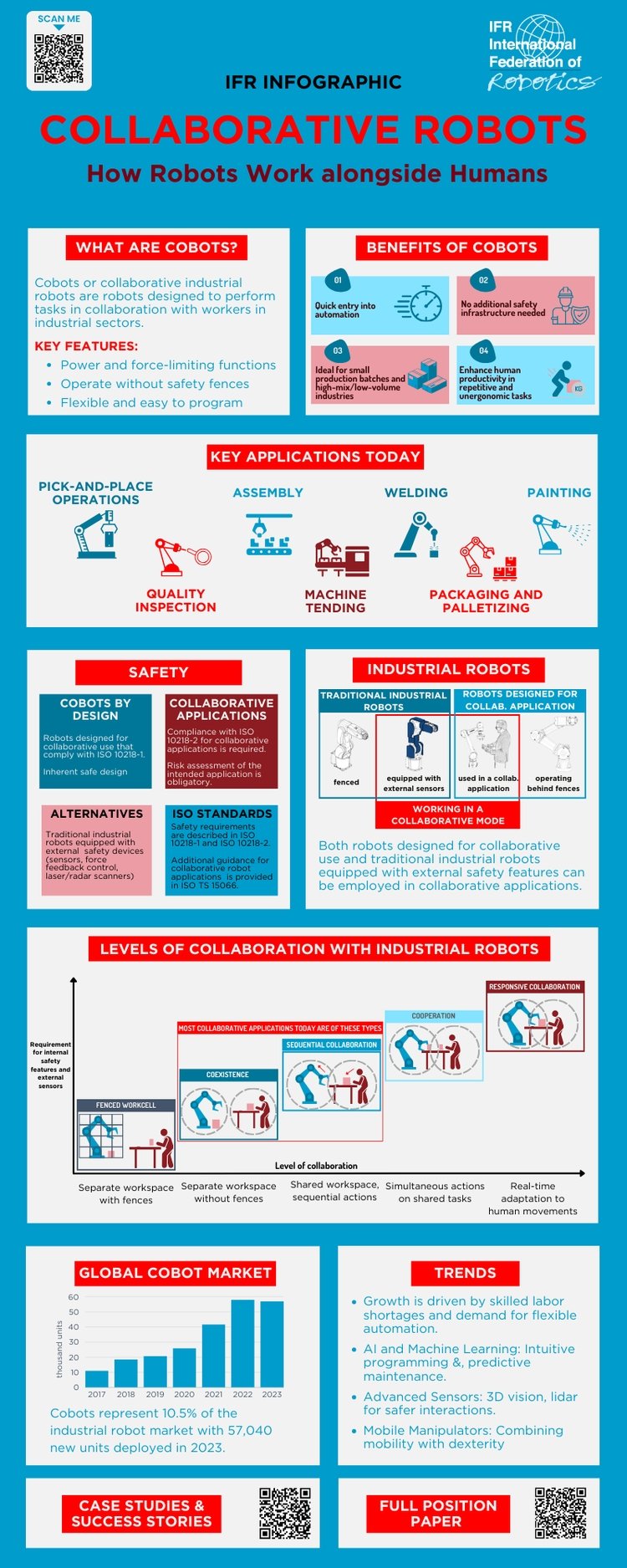

IFR updated its position paper on collaborative robots (aka cobots) and how they work alongside humans. As the world continues to face mounting labor shortages, robotics has emerged to address this challenge. In fact, cobots reached a market share of 10.5% of industrial robots installed worldwide in 2023.

Cobots offer a quick entry into automation. They are easy to program; some are programmable by hand guiding – called “lead-though teach” – or through tablet interfaces. Cobots most often require no additional safety measures to implement on the factory floor. This allows fenceless operation directly integrated into existing production areas. They can adapt flexibly by using Plug & Play technologies for example. This is especially attractive for companies which do not have engineering experts, for companies with smaller production batches and in industries where production needs are constantly changing.

Cobots vs. traditional industrial robots

Cobots typically have some trade-offs compared to traditional industrial robots. This is due to their design and purpose to safely work alongside humans: Cobots are currently not applicable e.g. for processes that require high payloads and high speeds. Their lightweight design supports easy relocation and simplified integration into mobile robot platforms. Cobots are used in many setups where a direct human-robot interaction is not required. Traditional industrial robots can be an alternative in those cases. However, cobots have additional safety functions and capabilities that are useful for many applications.

In cases where human intervention is needed, industrial robots that are equipped with external safety measures can provide good solutions without compromising velocity and payload. The safety measures include e.g. laser scanners, locking safety gates or safety mats.

Manufacturing industries have been early adopters of cobot technology. This includes automotive, electronics, aerospace, consumer goods, pharmaceuticals, logistics and warehousing. Due to a cobot’s ease of use, we typically see industries that require low volume high mix production. This can include welding, machine tending, bin picking and end of line palletizing.

Trends driving cobot development

The shortage of skilled workers will drive the development of automated solutions and will re-establish manufacturing infrastructure closer to the consumers. New applications are developed for cobots, continuously expanding their potential fields of use – from simple handling, through welding, to painting, dispensing and assembly.

Cobot manufacturers are developing machine learning systems so that cobots can “learn”. This modular technology and learning approach leads to opening further doors to expand what a cobot can do while unattended. In future, new sensors, vision technologies and artificial intelligence (AI) will allow robots to respond in real-time to changes in their environment and thus work safely – and more responsively - alongside human workers.

Cobot market

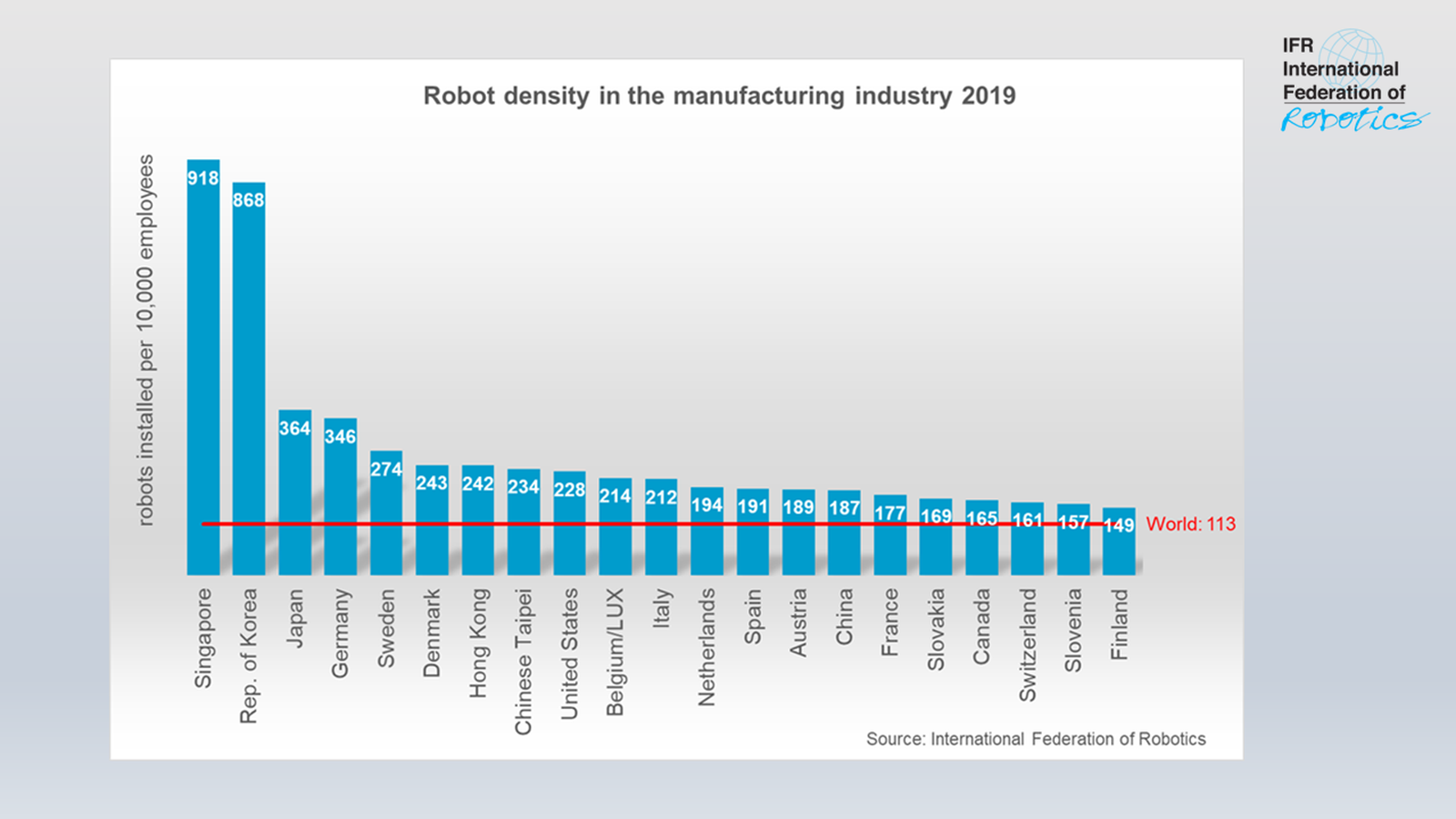

Cobots accounted for 10.5% of the total 541,302 industrial robots installed in 2023. IFR’s statistics show: collaborative robots will complement – not replace – investments in traditional industrial robots which operate at much faster speeds and will therefore remain important for improving productivity in response to tight product margins.

Download this and all other IFR Position Paper for free*.

*requires registration