For over 15 years HK-CON Maschinenbau GmbH has been designing and building high-tech metal cutting machines at its Fulda site. HK-CON recently realised a complete installation for Georg Fischer Fittings GmbH, manufacturer of cast iron fittings.

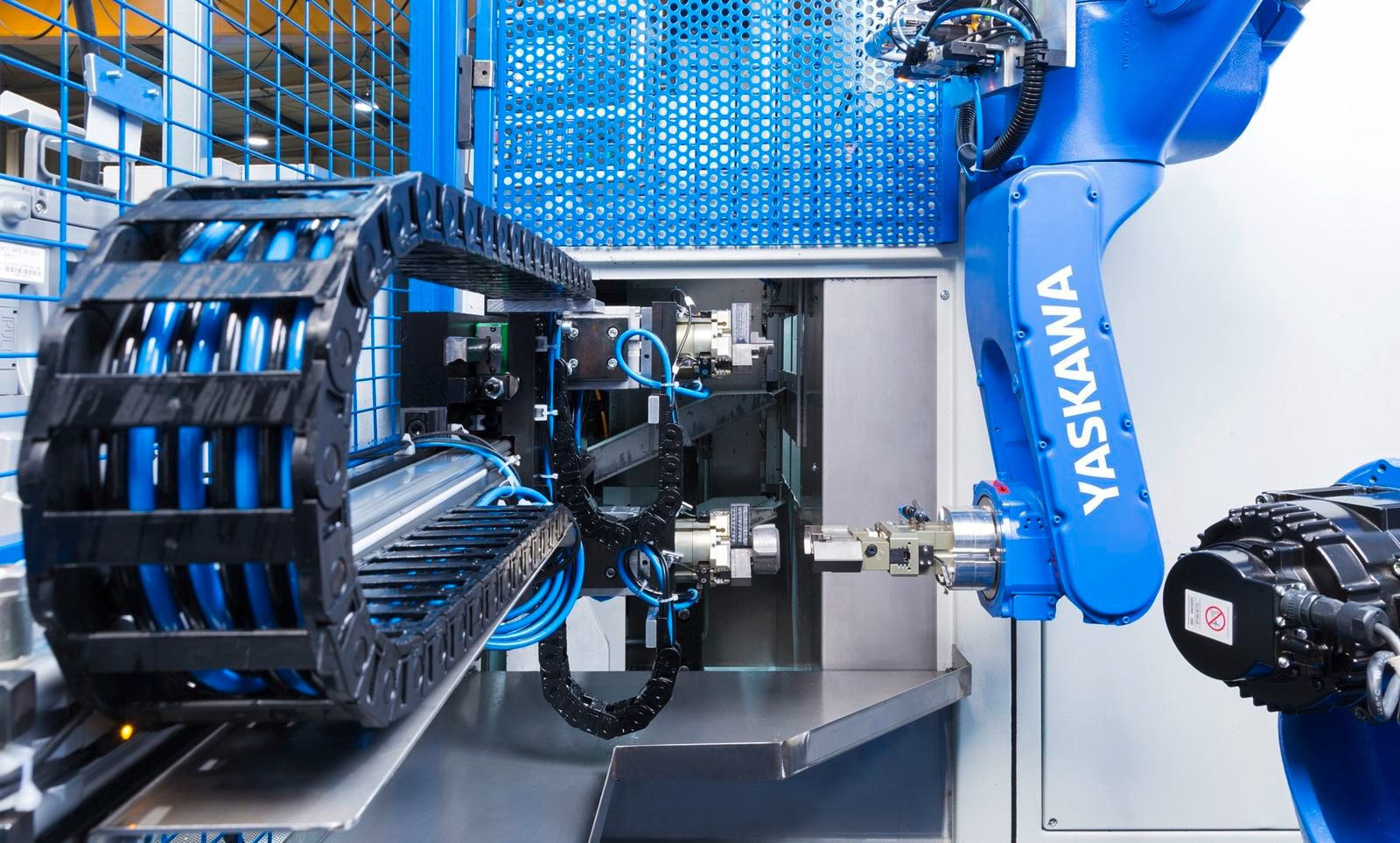

Besides replacing three previous installations, it satisfies the high customer expectations with regard to productivity and achieves exemplary cycle times despite its extremely complex design. Four Yaskawa handling robots are responsible for feeding: two Motoman MH12 and two Motoman MH5 robots, each of them operated with a DX 200 high-performance control.

At HK-CON Maschinenbau GmbH over 60 employees design and construct turning centres at a production plant of almost 4,000 m². Its product range comprises one- to two-spindle turning and milling centres which can be used, among other things, for turning, grinding or milling. About 99% of customers call for complete systems that can be integrated into their processes. In addition, the Fulda-based high-tech company offers professional services for the design and maintenance of machines. Customers from the automotive industry also employ HK-CON solutions. As David Reinmold, Head of Sales, assures: “Our solutions enable reductions of over 50% in unit costs, particularly in large-scale manufacturing, resulting in a drastic cut in overall production costs.” That also has an economic component: the lower unit costs once again make it profitable to produce in central Europe.

For Georg Fischer Fittings GmbH, based in Traisen/Austria, HK-CON has designed and constructed a complete machining centre for manufacturing malleable cast iron fittings. The challenge presented by the project: the installation was to be capable of manufacturing a total of 35 different final products – with an extremely low cycle time of five seconds per unit for the part with the shortest cycle time. Furthermore, it was critical that only absolutely immaculate parts be delivered to the cutting machine. That is the task assigned to the four Yaskawa Motoman robots – two MH 12 and two MH5 models – working in concert with the DX200 high-performance controls. They are supported by a camera system with a total of 6 cameras. The control software employed here is the MotoPlus SDK. As an interface it is responsible for communication with the cameras and regulates cooperation with them.

35 possible final products

In simplified terms, the facility has two turning centres located opposite to one another. Upstream of each of these are two Motoman robots. The robots are arranged cross-wise: the same models are situated bottom left and top right, and vice versa. This configuration has proved to be effective in achieving the necessary working range for loading – the machines could not be located closer together for work safety reasons.

The facility has a bunker for bulk material and a feeding bench for special parts, which are inserted in the correct orientation via pallets. The system can be operated either double-sided by mass feeding or one-sided for special parts, and the parts are delivered already sorted. Georg Fischer GmbH produces a total of nine different cast iron fitting components with this facility. The different sizes result in a total of 35 different final products. Hitherto, three of their own systems were required for their manufacture. Retooling times are only incurred in the new HK-CON system when a different component has to be machined. For the most part, varying sizes can be inserted without further conversion.

Robots and cameras work together

Three cameras are situated on each side, close to the robots. The first of these tell the Motoman robots where and how the parts are delivered and whether they are the desired components. Unwanted parts can already be eliminated at this point. If it is a required component, the camera inspects it for major defects and communicates the exact orientation and position to the robot. The robot now has all the information needed to pick it up. Once it has completed this step, it scans the part for casting defects, and in the case of doubt deposits it in a crate. If the part is free of defects, the handling robot moves to the next camera and rotates it three to four times, so that it can check all six to eight sides. At this point the camera checks whether sprue remains on the component. Here again, the robot has an opportunity to reject it. In addition, the camera recognises the orientation of the parts, enabling the robot to deposit them either in a subsequent turning station or directly on a belt conveying them to the next robot.

Correct parts which are flawless and lie in the right position are conveyed to the next robot. The third camera checks the position and angle of rotation. Finally, the second robot picks up the part from the outside and transfers it to the turning centre. Each of the two machines at the turning centre is two-spindle. This enables each of the two cutting machines to work two parts simultaneously and eject four finished parts, i.e. parts with the shortest cycle time, every 20 seconds. The machine runs 690 shifts per year. In this time it must produce a predetermined number of cast iron fittings.

If a different component is to be worked, a fitter may need to replace the robot jaws or adjust the delivery system. The different programs were taught, i.e. programmed, by HK-CON. The fitter only needs to select them. Every second counts in mass production. The system can be retooled in only one hour per side. Only half an operator is needed to operate the system.

Fast, precise, stable

“Because cast iron is difficult to handle, designing the system was also a challenge for us. However, with Yaskawa’s Motoman robots MH12 and MH5, the respective DX200 controls and the MotoPlus SDK software to coordinate the camera, we succeeded in designing the feed system so that at the end only high-quality parts arrive at the turning centres for machining,” explains David Reinmold. “We built a highly flexible system with higher productivity. It operates very fast, with highest precision and stability, and requires less operating personnel.”

At the time of placing the order, the customer specified that the system should be equipped with Yaskawa handling robots. One of the reasons for this was the good price-performance relationship of Yaskawa products; the other was that exclusively Yaskawa robots had hitherto been used throughout the plant, and the employees had already been trained to use them.

Summary

Thanks to HK-CON’s complete installation for metal cutting, Austrian malleable cast fittings manufacturer Georg Fischer GmbH was able to replace three old machines. For smooth running production it is important that only absolutely immaculate components be delivered to the turning centres. With the Yaskawa Motoman robots (two MH12 and two MH5 models) the DX200 controller and the MotoPlus interface for coordination of the cameras, the installation achieves precise results with extremely short cycle times. In addition, the system is highly flexible: a total of 35 different final products can be manufactured.

All pictures ©: YASKAWA