KR QUANTEC prints 3D facades for Belgian construction group

Building sustainably

Mar 23, 2022 — Printing concrete rather than pouring it: the Belgian BESIX Group is working to revolutionize traditional construction methods. A KR QUANTEC from KUKA is assisting in this. It prints columns, sculptures and facade elements in 3D using concrete. Fast and environmentally friendly.

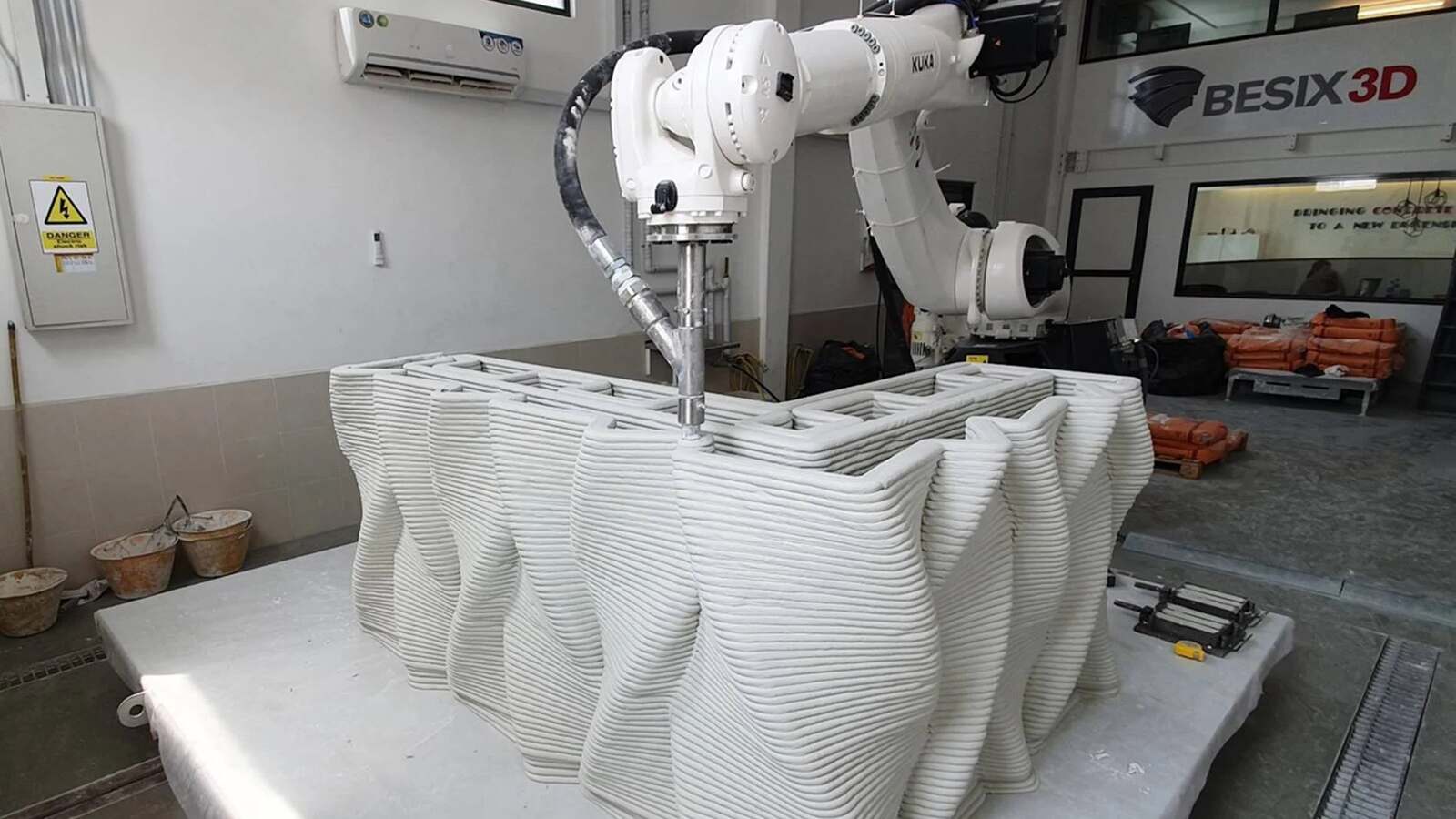

The articulated arm of the KR QUANTEC is equipped with a nozzle for 3D concrete printing. © KUKA

290 concrete panels form the facade of the BESIX 3D studio in Dubai, part of the Belgian BESIX Group. 290 panels, each of which was printed in around ten minutes with the aid of a KUKA robot and then simply mounted on the building on site. It was the construction group’s first groundbreaking project and is currently considered the largest 3D-printed concrete facade in the world.

Fast, environmentally friendly and safe: 3D printing with concrete is set to revolutionize traditional construction methods. The additive manufacturing process avoids waste and delivers customized solutions or even entire series in just a few hours. Construction companies around the world are currently working to find the best method for 3D printing. One of them is the BESIX Group, headquartered in Brussels. Founded in 1909, the company set up a 3D studio in Dubai for this purpose in December 2018 and installed a robot from the KR QUANTEC family for carrying out the printing.

Strong partners for new methods in additive manufacturing

“For us, it was particularly important to find a reliable partner at the start of the project who was prepared to think in new dimensions with regard to printing. We found this partner in KUKA and can now implement our project automatically,” says Benoît Meulewaeter, Senior Project Manager for Design and head of the BESIX 3D team. Together with automation specialist KUKA from Augsburg, the company developed its robot application for 3D printing with concrete as the material. All the shaped elements required by the customer are modeled in advance using 3D software.

3D software passes specifications on to KR QUANTEC

“There are no limits in additive manufacturing – even for complex requirements. 3D printing enables us to individually produce any customized shape,” explains Meulewaeter. Once the model is ready, the software transfers the data to the KR QUANTEC, which has a nozzle on its articulated arm for 3D printing. The robot then prints sculptures, facade elements and other components for buildings layer by layer according to the specifications. Fast and effective. In this way, a two-meter high column is produced in less than an hour.

No waste and low CO2 emissions through use of a robot

The customer also has flexibility when it comes to color: colorfast pigments can be mixed into the concrete material before printing to achieve the customer’s desired color. The robot not only carries out its work quickly, but also does so in near silence and in an environmentally friendly manner. The liquid concrete material is converted 1:1 into the end product, so that no waste is produced in the process. Use of the KR QUANTEC also reduces CO2 emissions since the robot can print the desired prefabricated concrete element directly at the construction site and it does not have to be specially transported.

3D printing with environmentally friendly material

Benoît Meulewaeter notes: “Through 3D printing using concrete, we are resolutely pursuing our corporate goal of offering efficient and environmentally friendly solutions.” KUKA provides support here as well. Alois Buchstab, head of the KUKA team overseeing the 3D project, says: “We are delighted that the BESIX Group has chosen KUKA as a cooperation partner. Thanks to our energy-efficient robotic solutions and expertise, we are living up to our responsibility to create a sustainable future.”

The BESIX 3D team is currently working with other partners to develop environmentally friendly concrete mixtures for additive manufacturing. These can be used in areas such as the construction of breakwaters. The company is also considering having the KUKA robot print directly on site in order to avoid transport costs. “We are highly satisfied with our collaboration and certainly will be able to move forward with many more projects with KUKA in the near future,” says Benoît Meulewaeter. The company is considering expanding its production facility in Dubai or even opening similar studios in Belgium or the Netherlands.